A chestnut processing and screening machine

A sieving machine and sieving technology, applied in the fields of sieving, solid separation, chemical instruments and methods, etc., can solve the problems of poor sieving efficiency, increase of operators, high noise, etc., achieve high degree of freedom and improve sieving The effect of efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention.

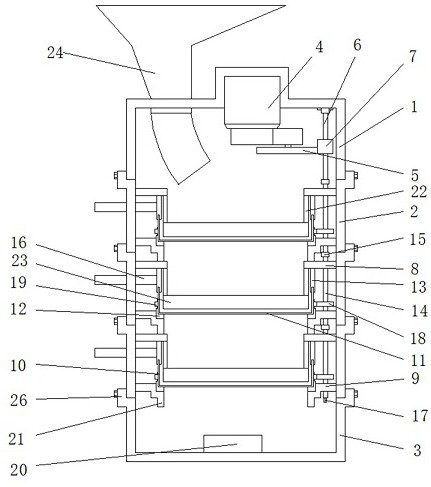

[0019] see figure 1 , the specific embodiment is realized by adopting the following technical scheme, which includes a machine head box body 1, the bottom of the machine head box body 1 is provided with a screening device that is buckled and fixed with it, and the described screening device is composed of several sequentially It consists of a fastened and fixed screening box body 2, and a final collection box body 3 that is fastened and fixed with it is installed at the bottom of the screening device;

[0020] The head box body 1 is a hollow tubular structure with an opening at the bottom as a whole, a motor assembly 4 is embedded in the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com