Automatic slag filter for ground gangue selection

A slag filter, automatic technology, applied in the direction of spring/shock absorber, vibration suppression adjustment, chemical instrument and method, etc., can solve the problems of low efficiency, poor screening effect, unsafe, etc., to avoid damage to the device and improve practical Longevity and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

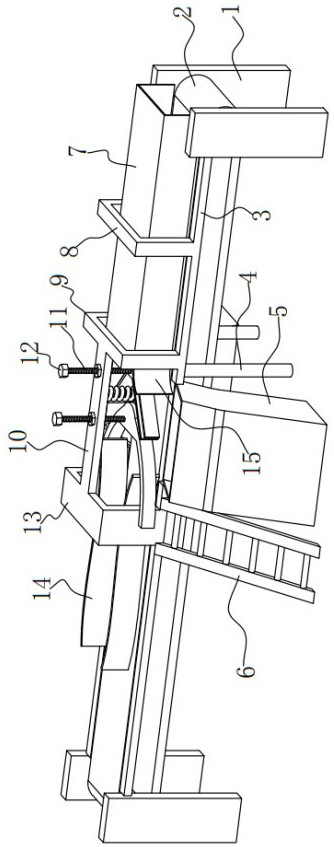

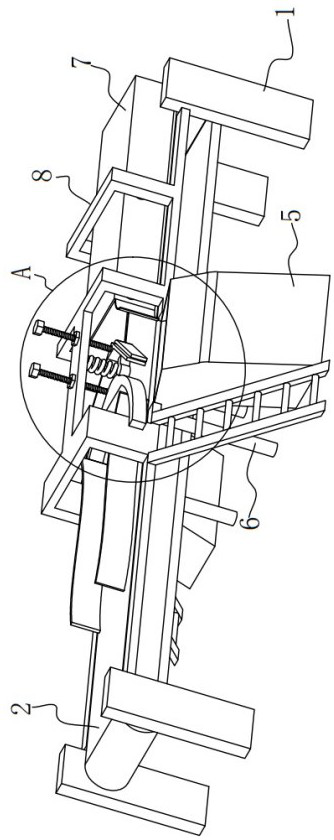

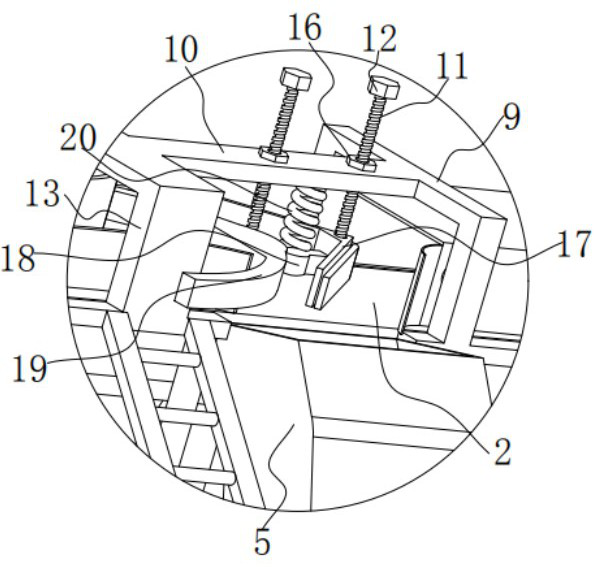

[0024] see figure 1 with figure 2 , the present invention provides the following technical solutions: an automatic slag filter for ground gangue selection includes support feet 1, two sets of support feet 1 are provided, two sets of support feet 1 are provided, and a conveyor belt 2 is arranged between the two sets of support feet 1 , two connecting plates 3 are fixed between each set of supporting feet 1, and the upper ends of the plurality of connecting plates 3 are sequentially fixed with a third supporting plate 13, a second supporting plate 9 and a first supporting plate 8 from left to right. A crossbeam 10 is fixed between the three support plates 13 and the second support plate 9, the lower end of the crossbeam 10 is fixed with a connection block 18 by a spring 20, and the left and right ends of the connection block 18 are respectively fixed with a second filter plate 19 and a first filter plate 17. There is a gap between the lower ends of the first filter plate 17 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com