Enameled wire paint surface scraping machine

An enameled wire varnish, small motor technology, applied in mechanical equipment, chemical instruments and methods, cleaning methods and utensils, etc., can solve problems such as laboriousness and inability to scrape off insulating paint, and achieve the effect of avoiding residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

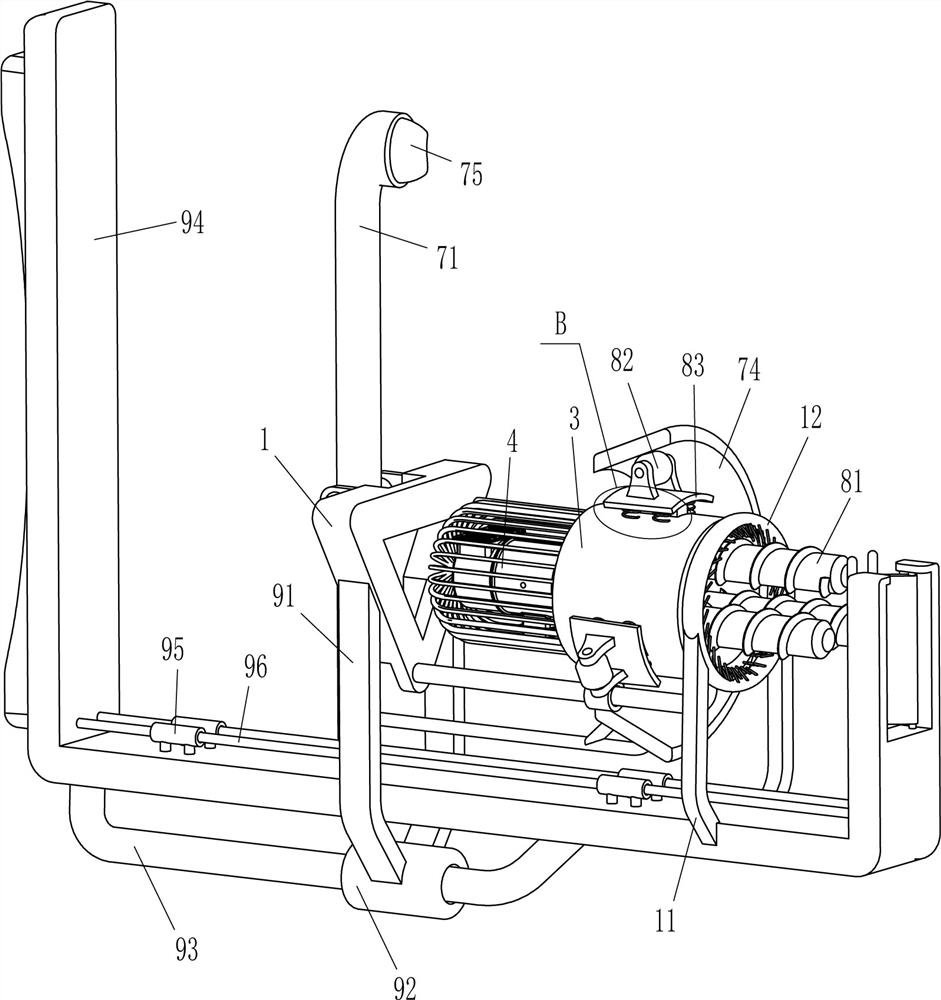

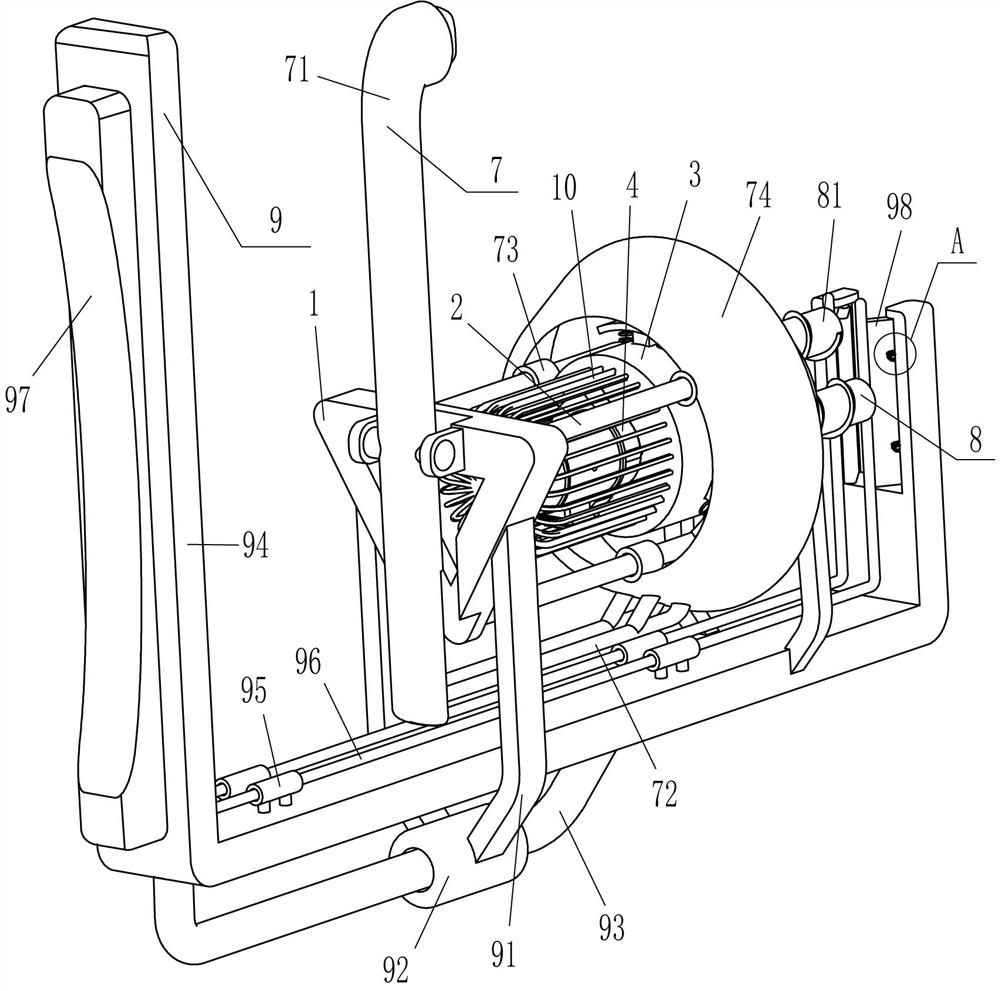

[0024] A kind of enameled wire paint surface scraping machine, such as figure 1 , figure 2 , image 3 ,and Figure 5 As shown, it includes a triangular plate 1, an L-shaped rod 2, a cylinder 3, a small motor 4, a rotating shaft 5, a first gear 6, a driving mechanism 7 and a scraping device 8, and the right side of the triangular plate 1 is fixedly connected with three L-shaped rods 2, a cylinder 3 is fixedly connected between the inner ends of the three L-shaped rods 2, and the center of the left side of the cylinder 3 is rotatably connected with a rotating shaft 5, and the right end of the rotating shaft 5 is fixedly connected with a first gear 6, the cylinder 3 A small motor 4 is installed in the middle of the outer left side, the end of the output shaft of the small motor 4 is fixedly connected with the left end of the rotating shaft 5, the cylinder 3 is provided with a scraping device 8 in the circumferential direction, and a driving mechanism is provided between the L-...

Embodiment 2

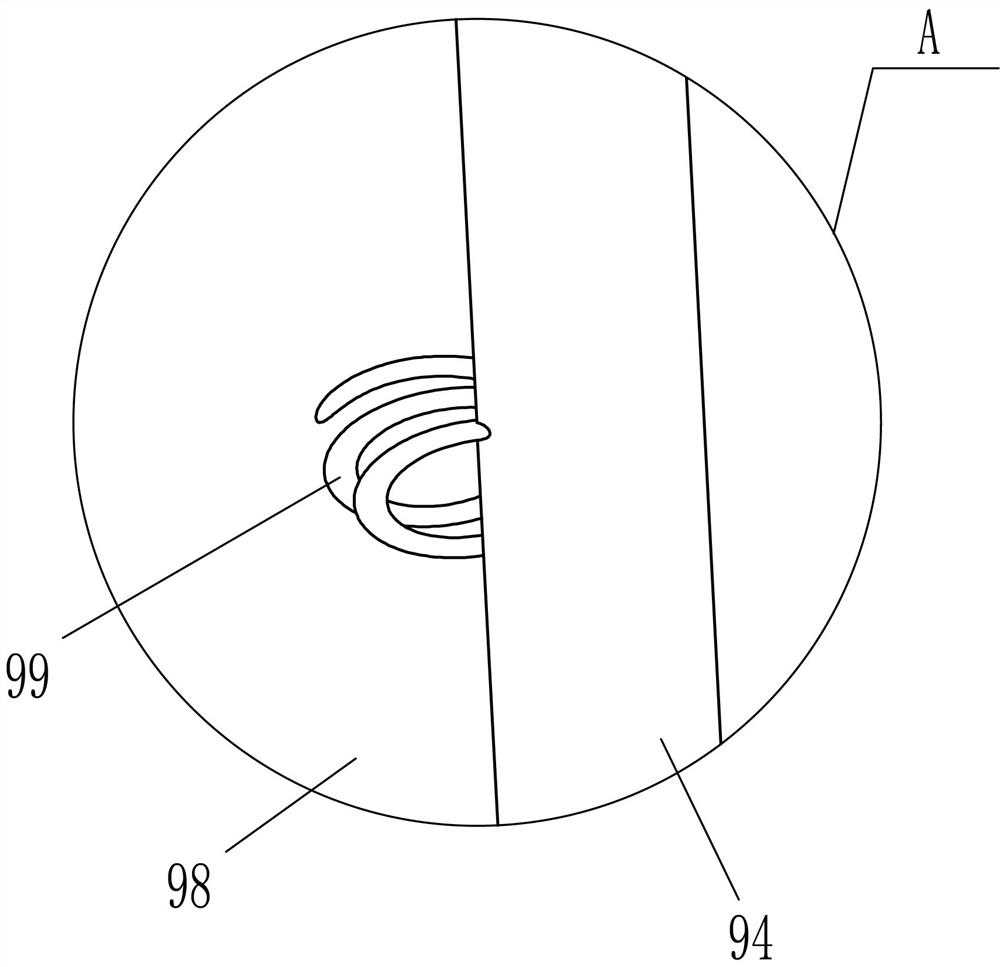

[0031] On the basis of Example 1, such as figure 1 and Figure 4 As shown, a clamping mechanism 9 is also included, and the clamping mechanism 9 includes a vertical bar 91, a first guide sleeve 92, a u-shaped bar 93, a u-shaped plate 94, a second guide sleeve 95, an L-shaped slide bar 96, a push Plate 97, splint 98 and the second spring 99, the middle part of the front and rear sides of the triangular plate 1 are all fixedly connected with vertical bars 91, and the first guide sleeve 92 is fixedly connected between the bottom ends of the front and rear sides of the vertical bars 91, inside the first guide sleeve 92 The sliding type is provided with a u-shaped bar 93, and a u-shaped plate 94 is fixedly connected between the two ends of the u-shaped bar 93, and the upper side of the right part of the u-shaped plate 94 is connected with a splint 98 symmetrically rotated forward and backward, and the upper and lower sides of the outer surface of the splint 98 A second spring 99 i...

Embodiment 3

[0034] On the basis of embodiment 1 and embodiment 2, such as figure 1 and figure 2 As shown, a protective cover 10 is also included, and the outer left side of the cylinder 3 is circumferentially fixed with the protective cover 10 , and the small motor 4 is located in the protective cover 10 .

[0035] Also includes support rod 11 and annular wire brush 12, U-shaped plate 94 is fixedly connected with support rod 11 on the right side of the lower part of the front and rear sides, and is fixedly connected with ring wire brush 12 between the tops of the front and rear sides of support rod 11, scraping roller 81 is located in the ring wire brush 12 and is in contact with it.

[0036] When the small motor 4 is in use, the protective cover 10 can protect the small motor 4, so that foreign objects can be prevented from smashing the small motor 4 and causing it to be unusable.

[0037] When the scraping roller 81 rotates to scrape off the insulating varnish on the enameled wire, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com