Integrated device for winding and taking up of textiles

A technology of winding and threading rollers, applied in the textile field, can solve the problems of easy loosening of yarns when taking up, and achieve the effect of improving quality, avoiding loosening of yarns, and avoiding loosening of take-ups.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

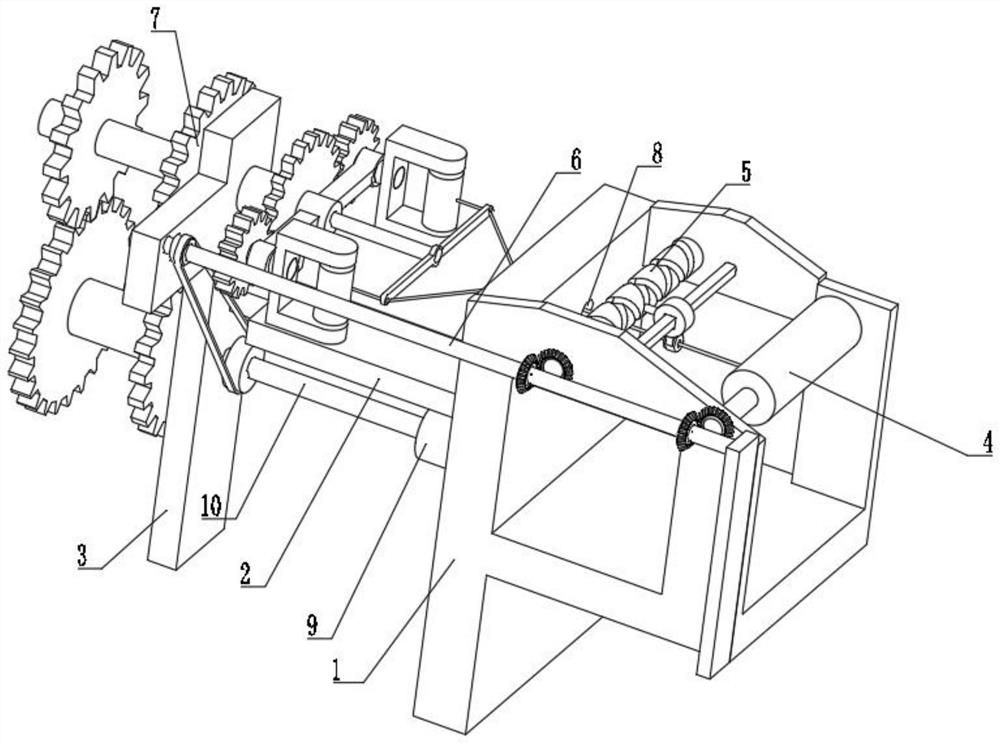

[0029] see Figure 1-5 , an integrated device for textile winding and take-up, comprising a fixed base 1, the left side of the fixed base 1 is respectively fixedly connected with a connecting plate 2 and a motor 9, the motor 9 is located under the connecting plate 2, and the left side of the connecting plate 2 is fixed Connected with a support plate 3, the interior of the support plate 3 is provided with a transmission mechanism 7, the output end of the motor 9 is fixedly connected with a transmission shaft 10, the surface of the transmission shaft 10 is provided with a connection mechanism 6, and the inner wall of the fixed seat 1 is rotatably connected with a take-up wire The roller 4 is provided with a wire mechanism 5 inside the fixed seat 1 , and a threading hole 8 is opened inside the fixed seat 1 .

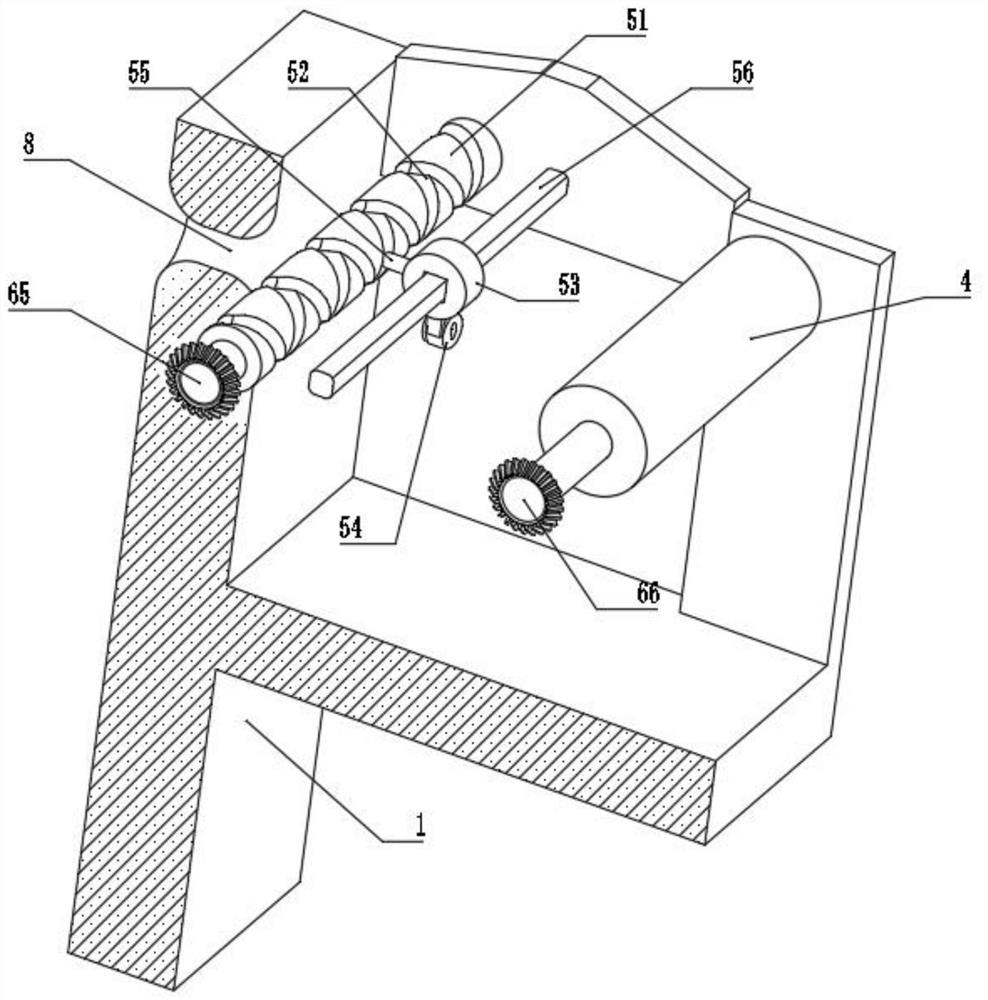

[0030] In this embodiment, the guide wire mechanism 5 includes a rotating roller 51, the surface of the rotating roller 51 is provided with a turning groove 52, the inner w...

Embodiment 2

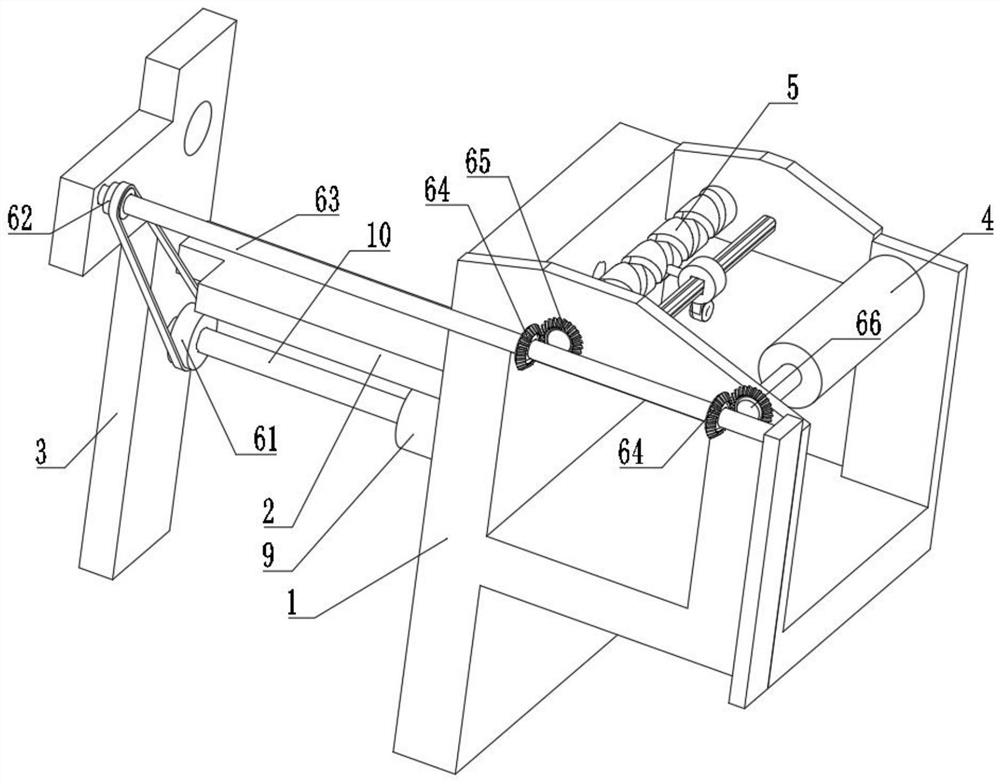

[0035] see Figure 6-7, the transmission mechanism 7 includes a first gear set 71, the right side of the first gear set 71 is fixedly connected with the left end of the transmission shaft 10, the surface of the first gear set 71 is engaged with a gear one 72 and a second gear set 73 respectively, the gears A connecting sleeve 77 is fixedly connected to the shaft center of -72, and the surface of the connecting sleeve 77 is connected to the inside of the second gear set 73 for rotation, and the surface of the second gear set 73 is connected to the inside of the support plate 3 for rotation, and the second gear set 73 The surface meshing with gear two 76, through the design of two gear sets, the rotation speed of gear two 76 and the rotation of the second gear set 73 has a certain speed difference, which improves the tightness in the winding process and avoids excessive speed and uncompact winding.

[0036] In this embodiment, the inside of the connecting sleeve 77 is fixedly co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com