An energy-saving and environment-friendly construction method for building exterior walls

A technology of energy saving, environmental protection and construction method, applied in the direction of building thermal insulation materials, buildings, building components, etc., can solve the problems of poor construction environment and dust, and achieve the effect of shortening working hours, reducing dust and avoiding errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

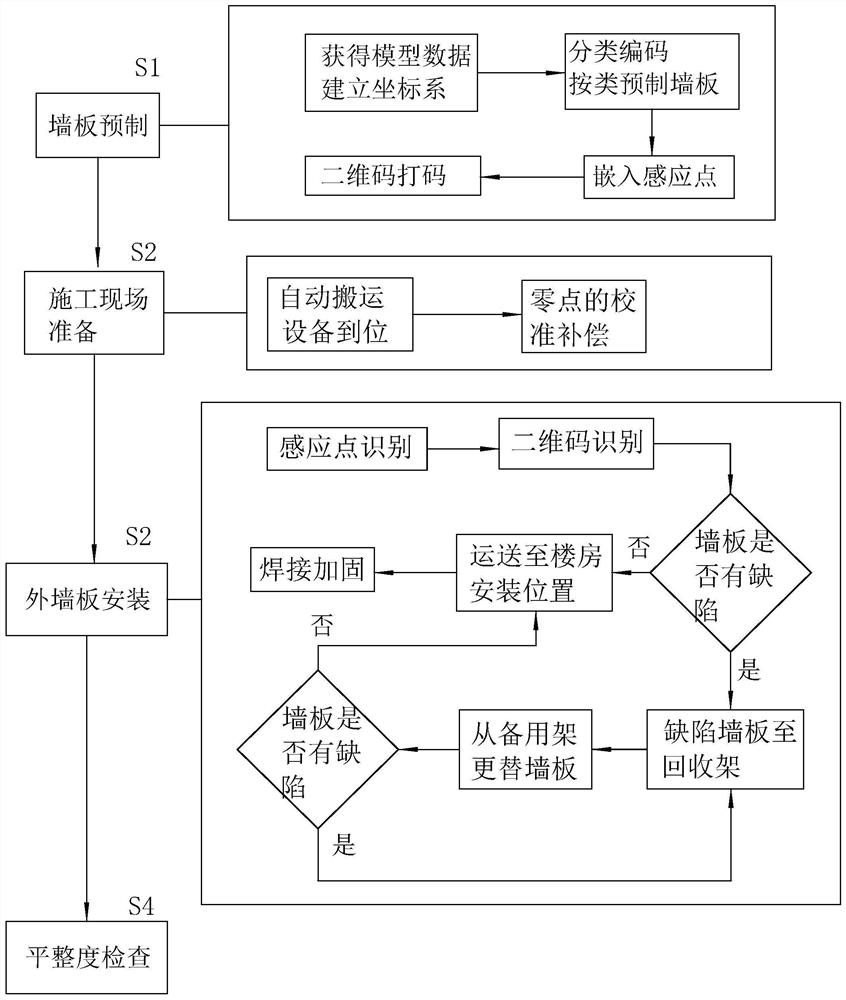

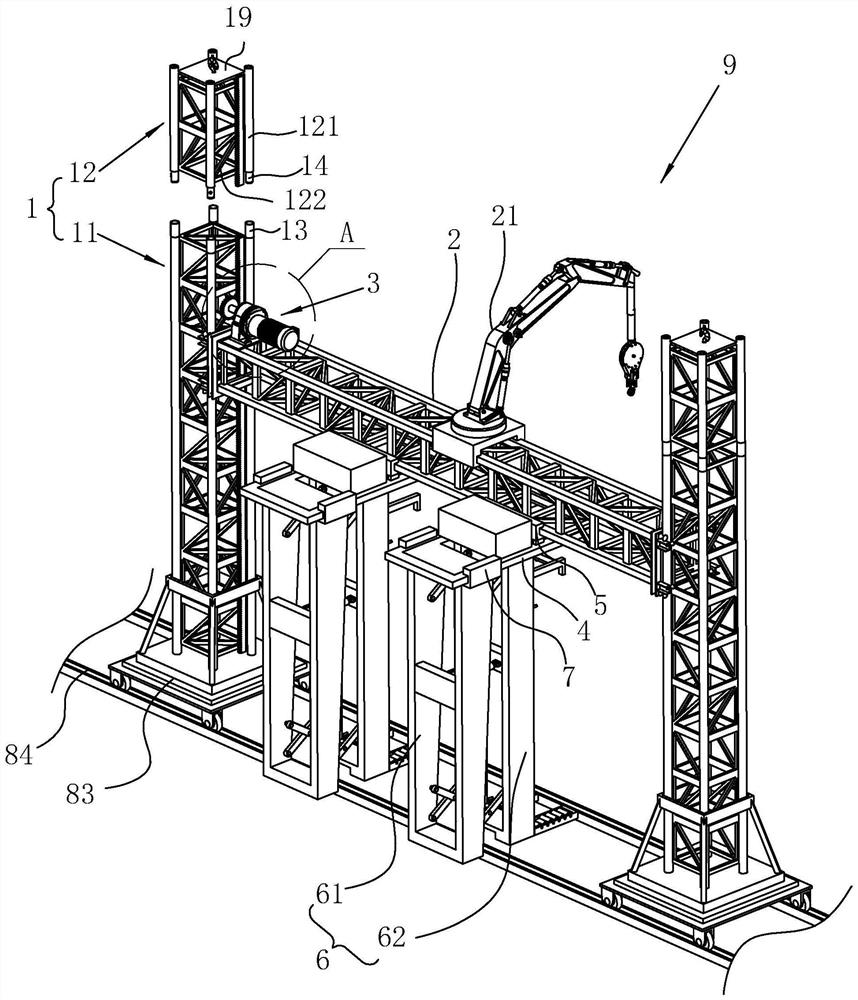

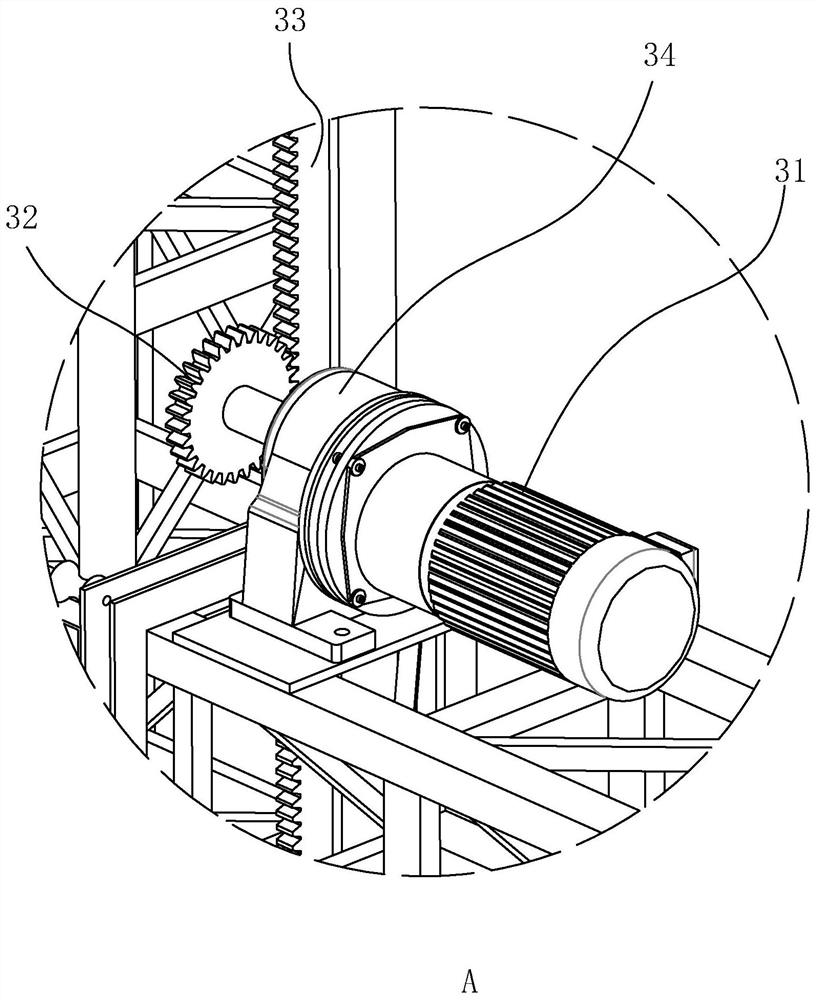

Method used

Image

Examples

Embodiment 2

[0072] Embodiment 2 is different from Embodiment 1 in that a full-load detection mechanism is provided on the spare rack, and the full-load detection mechanism is an infrared sensor installed on the outermost side of the transfer rack. Also no longer move the wall panels on the transfer rack back to the standby rack after the wall panels have been installed. Instead, the wall panels are continuously transferred to the transfer rack until it is fully loaded. After full load, the spare rack with the least number of wall panels is re-identified as the transfer rack.

[0073] In the above method, it is necessary to stack the spare wallboards of the same type close to each other, and during the construction process, the continuous construction of the same type of wallboards is the main method. This condition can select replaceable wall panels more quickly in the method of the present embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com