A cooling type mid-wave infrared athermalization optical lens

The technology of an optical lens and an infrared optical system is applied in the field of cooling type mid-wave infrared athermalization optical lens, which can solve the problems of poor imaging quality, high manufacturing cost, and many types of materials, and achieves easy assembly and adjustment, simple and compact structure, The effect of barrel length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

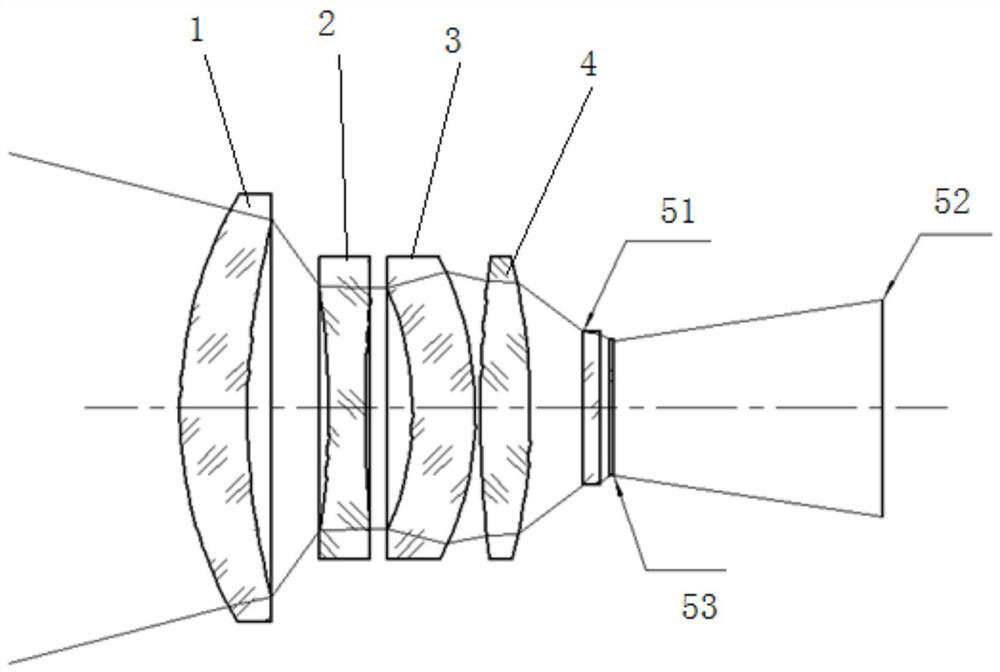

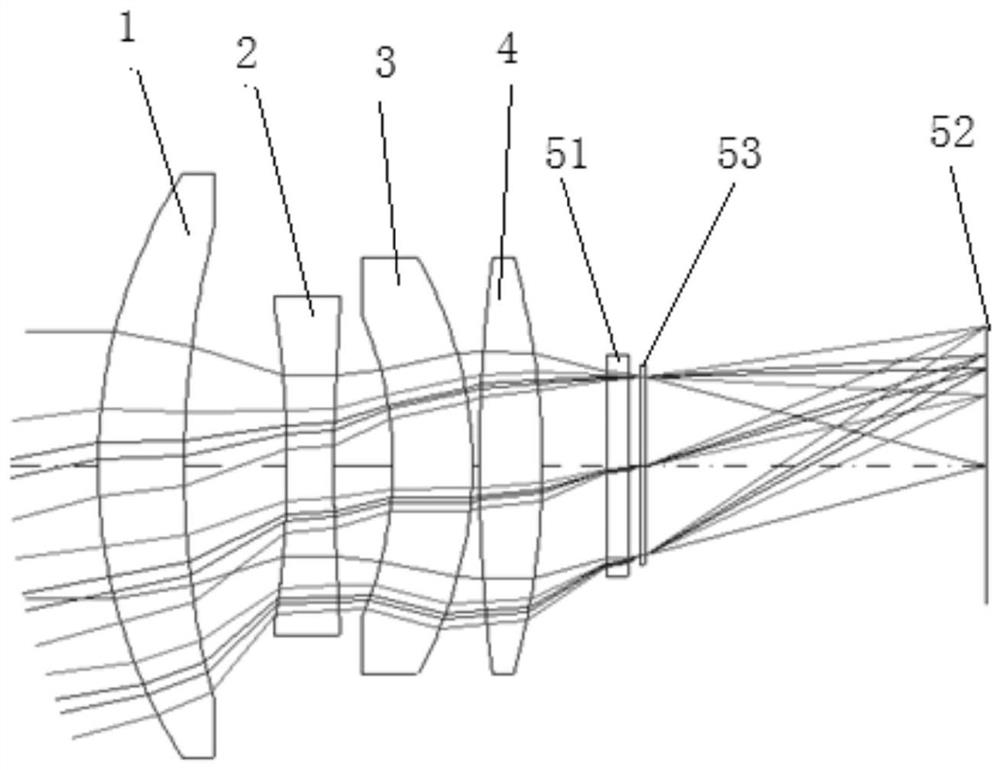

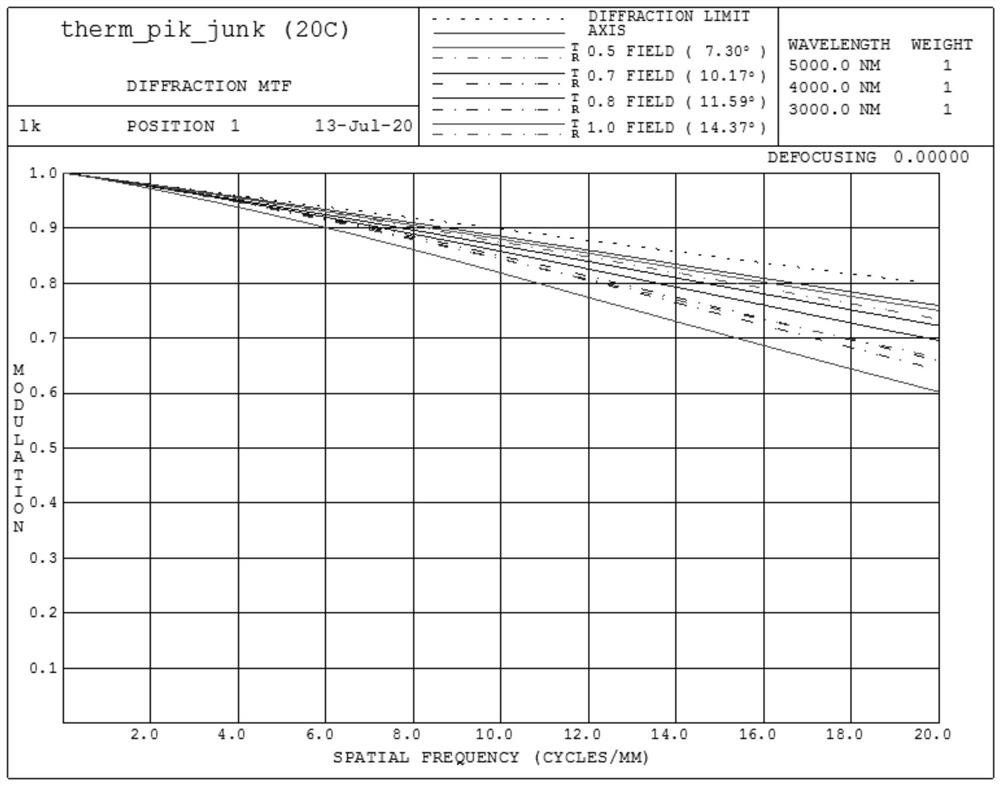

[0043] like figure 1 and figure 2 As shown, a cooling type mid-wave infrared athermalization optical lens includes a lens barrel and a mid-wave infrared optical system arranged in the lens barrel. The athermalization design of the optical system means that the temperature caused by the The thermal aberration is eliminated together with the geometric aberration, so that the optical system can image well in a large temperature range. The medium-wave infrared optical system of the present invention adopts the optical passive athermalization technology, and by matching the naturalized thermal difference coefficient of the optical material and the thermal expansion coefficient of the optical-mechanical structural material, the thermal defocus of each influencing factor is compensated each other, so that the medium-wave Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com