a broadband motor

A motor and broadband technology, applied in the field of broadband motors, can solve the problems of spring breakage and high stress, and achieve the effects of large driving force, good consistency, and enhanced tactile feedback effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

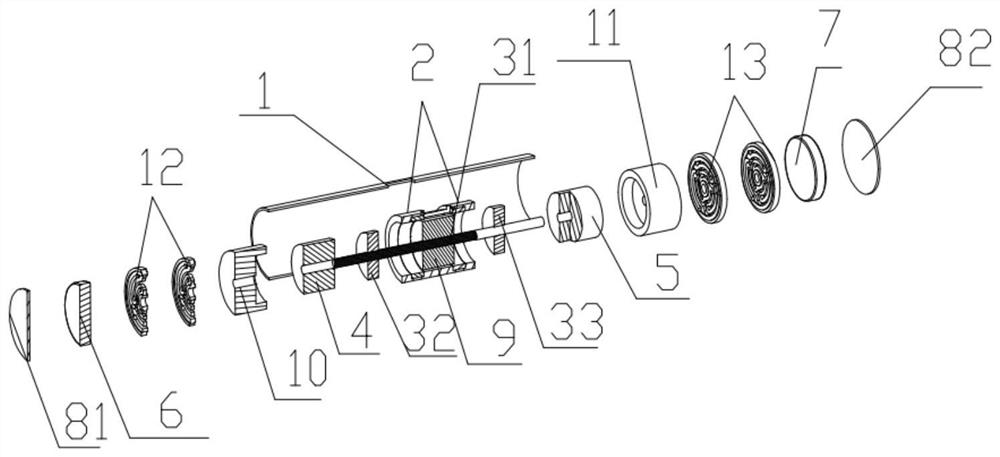

[0050] Example 1: Broadband motor with plastic spring

[0051] Such as Figure 1-16 As shown, a broadband motor provided in this embodiment includes a coil assembly, and the coil assembly includes two coils 2, a housing 1, a magnetic assembly, a connector 3, a mass and an elastic mechanism, and the magnetic assembly is arranged in the housing 1 , the magnetic assembly includes a first magnetic part 4 , a second magnetic part 5 , a third magnetic part 6 , a fourth magnetic part 7 and an inner magnetic part 9 .

[0052] The first magnetic part 4 and the second magnetic part 5 are located on both sides of the inner magnetic part 16, the first magnetic part 4 is provided with a third magnetic part 6 on the side away from the connecting part 3, and the second magnetic part 5 is provided with a fourth magnetic piece 7 on the side away from the connecting piece 3, the first magnetic piece 4 and the inner magnetic piece repel each other, the second magnetic piece 5 and the inner magn...

Embodiment 2

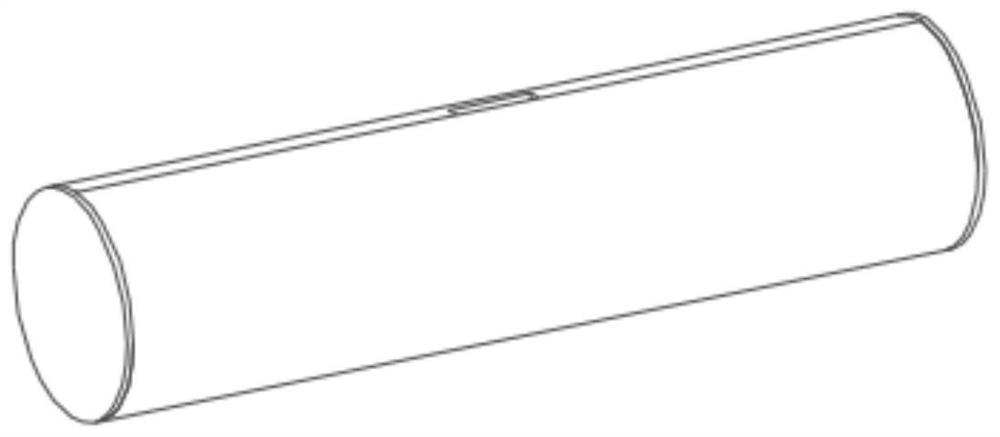

[0062] Example 2: Broadband motor with plastic spring

[0063] Such as Figure 17 As shown, the difference between this embodiment and Embodiment 1 is that: the shell 1 is different; and the coil supporting structure is canceled in this embodiment, and the shell in this embodiment is as follows Figure 18 As shown, the shell 1 is an integral cylindrical structure, the coil 2 is directly wound on the inside of the shell 1, the independent coil support structure is canceled, and the internal structure of the shell is directly set to support the coil; that is, the above-mentioned improvement can greatly Reduce part manufacturing cost and assembly cost.

[0064] The invention realizes the flexible adjustment of the vibration system f0 through the superposition of multiple plastic springs; through the structural design of the special plastic spring, the radial stiffness is increased, and it is rigidly connected with the shaft-shaped fixing part of the vibrator, so as to avoid the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com