Discharging device suitable for pipe fitting assembling production line

A technology for assembling production lines and pipe fittings, applied in the direction of conveyor objects, transportation and packaging, conveyors, etc., can solve problems such as vibration of finished products, and achieve the effects of ensuring quality, preventing loosening, and smooth transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

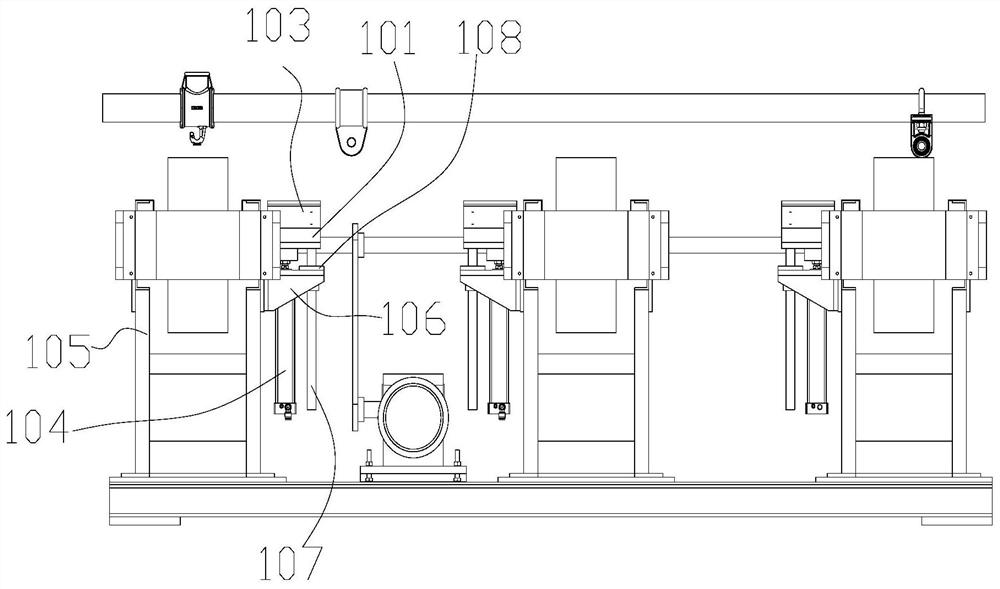

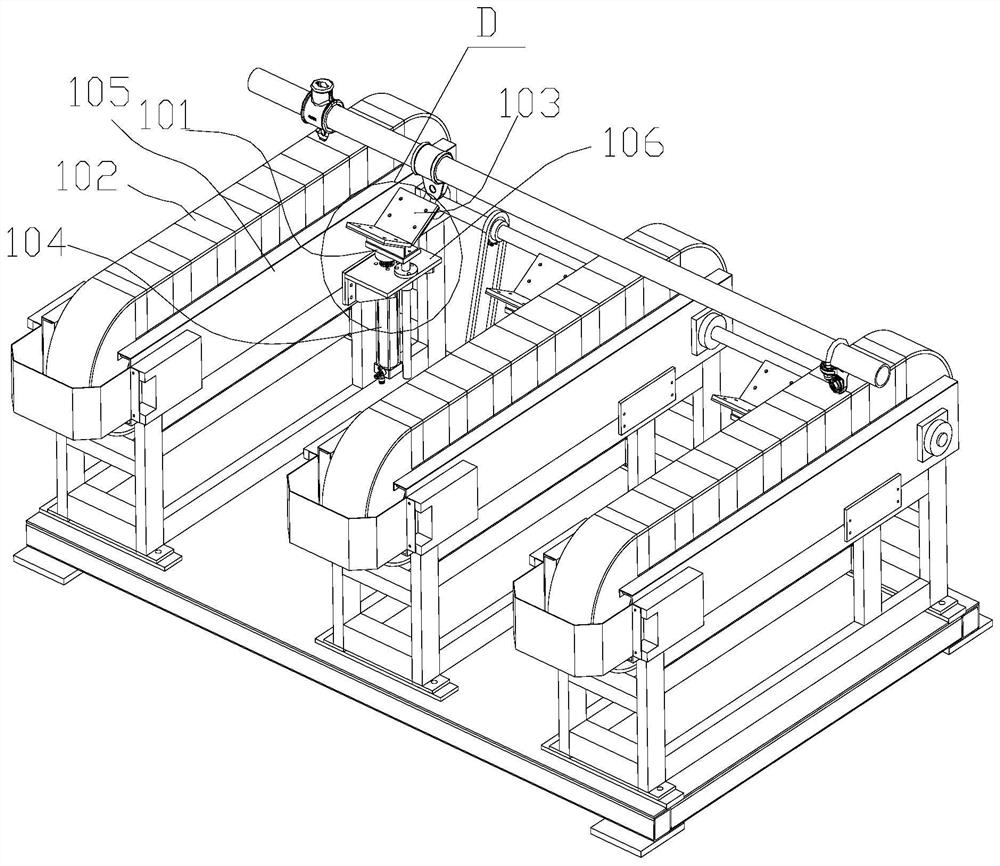

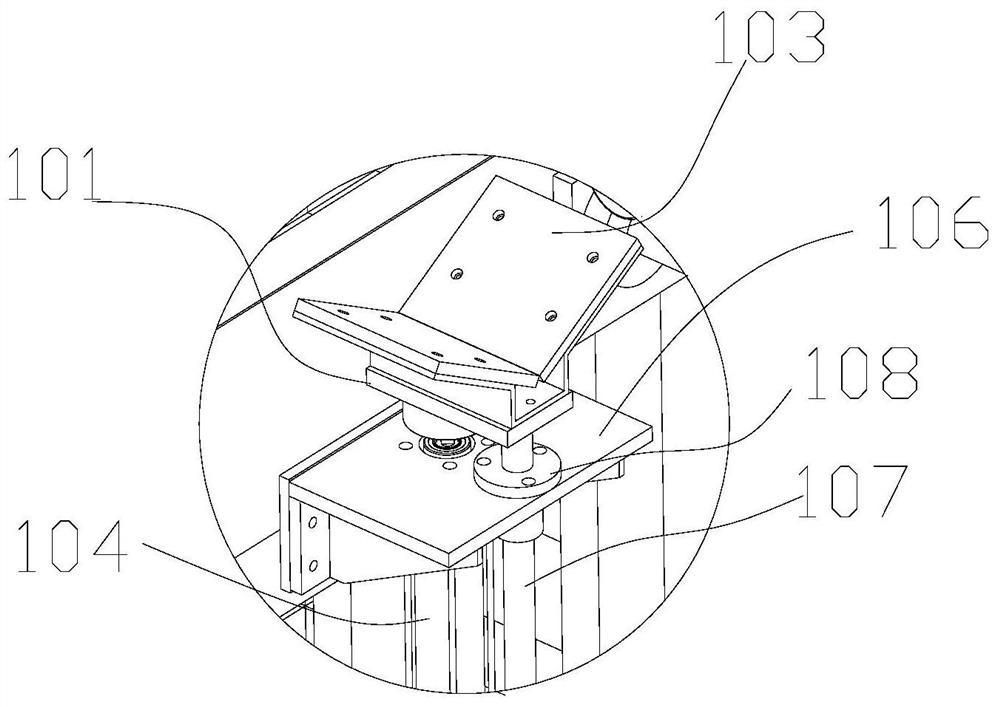

[0026] The production line can take the following embodiments:

[0027] Such as Figure 4-13 , a wrist-arm assembly production line, which sequentially includes a pipe fitting feeding device 1, a pipe fitting pretreatment device 2, a coding device 3, a pipe threading tightening device 4 and a finished product blanking device 5 according to the conveying direction of the production line, and the pipe threading tightening device 4 is at least Including two groups, each group of pipe threading and tightening devices 4 includes a feeding mechanism 41 that is arranged next to the conveying line and will be used to convey parts to the production line for pipes to pass through. The pre-installed screw tightening mechanism 42, the pipe threading tightening device 4 includes at least two groups, and the production line also includes a conveying device 6 that conveys the pipe fittings from front to back on the conveying line.

[0028] The pipe fitting feeding device 1 comprises a feedi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com