Novel movable end supporting device for rolling bearing mill

A technology of rolling bearing and supporting device, which is applied to the rigid bracket, bearing element, shaft and bearing of bearing components, etc., can solve the problems of poor sealing of the sealing device, inability to put the roller in, and the roller is out of the groove, so as to avoid the problem of moving , Simple structure, simple installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to clearly illustrate the technical characteristics of this solution, the following describes this solution through a specific implementation and in conjunction with the accompanying drawings.

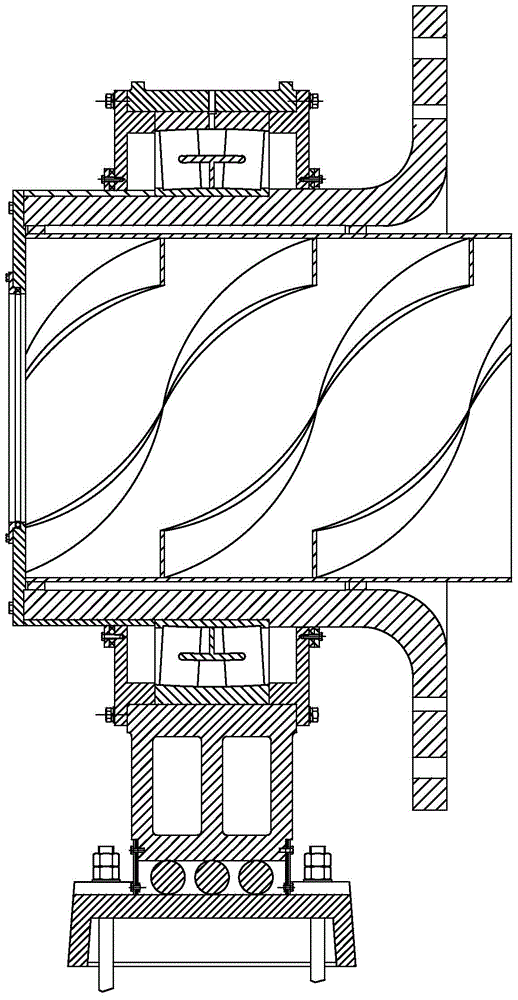

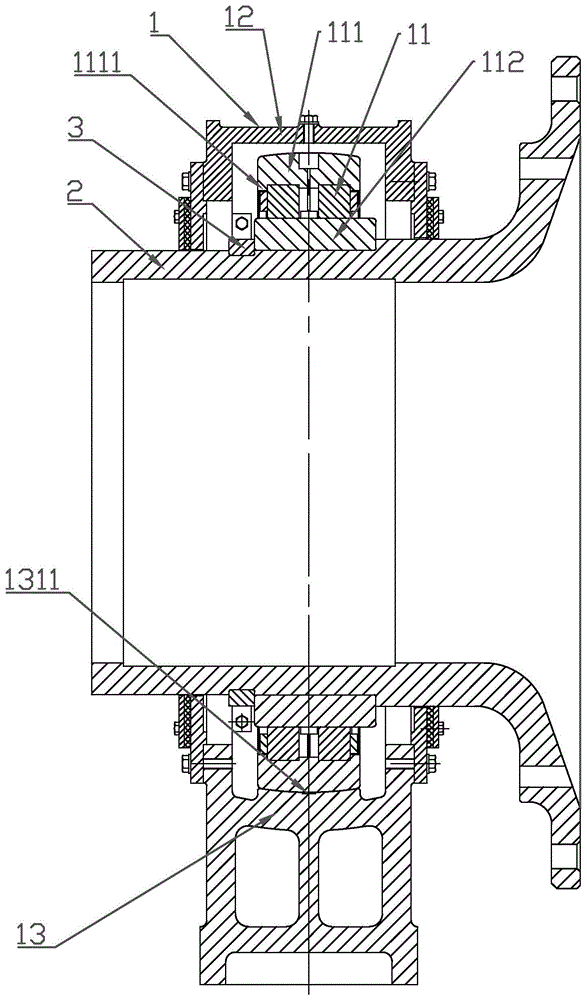

[0019] Such as Figure 2-5 As shown, a novel rolling bearing mill movable end support device of the present invention includes a bearing support body 1 and a hollow shaft 2. The bearing support body 1 and the hollow shaft 2 together constitute the movable end support device of the mill.

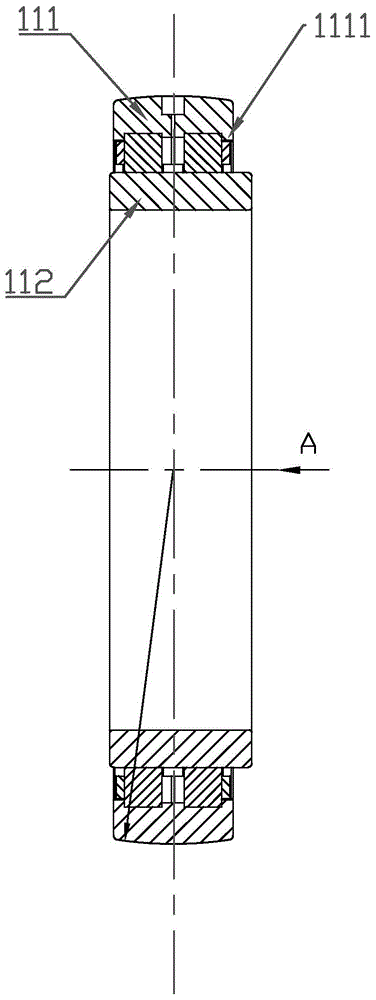

[0020] The bearing support 1 includes a rolling bearing 11, a bearing upper cover 12, and a bearing lower seat 13. The rolling bearing 11 is arranged inside a bearing housing composed of the bearing upper cover 12 and the bearing lower seat 13, and the bearing support The rolling bearing 11 of 1 is sleeved on the hollow shaft 2. The rolling bearing 11 is an outer spherical self-aligning double row cylindrical roller bearing, the bearing outer ring 111 of the rolling bearing is a spherical s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com