3D printing burn pressure mask based on silicone coating and manufacturing method thereof

A 3D printing and manufacturing method technology, applied in the direction of processing and manufacturing, manufacturing auxiliary devices, liquid material additive processing, etc., can solve the problems of not being able to meet pressure masks, materials that cannot be reheated and modified, and scar pressure that cannot be accurately realized. The effect of precise pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

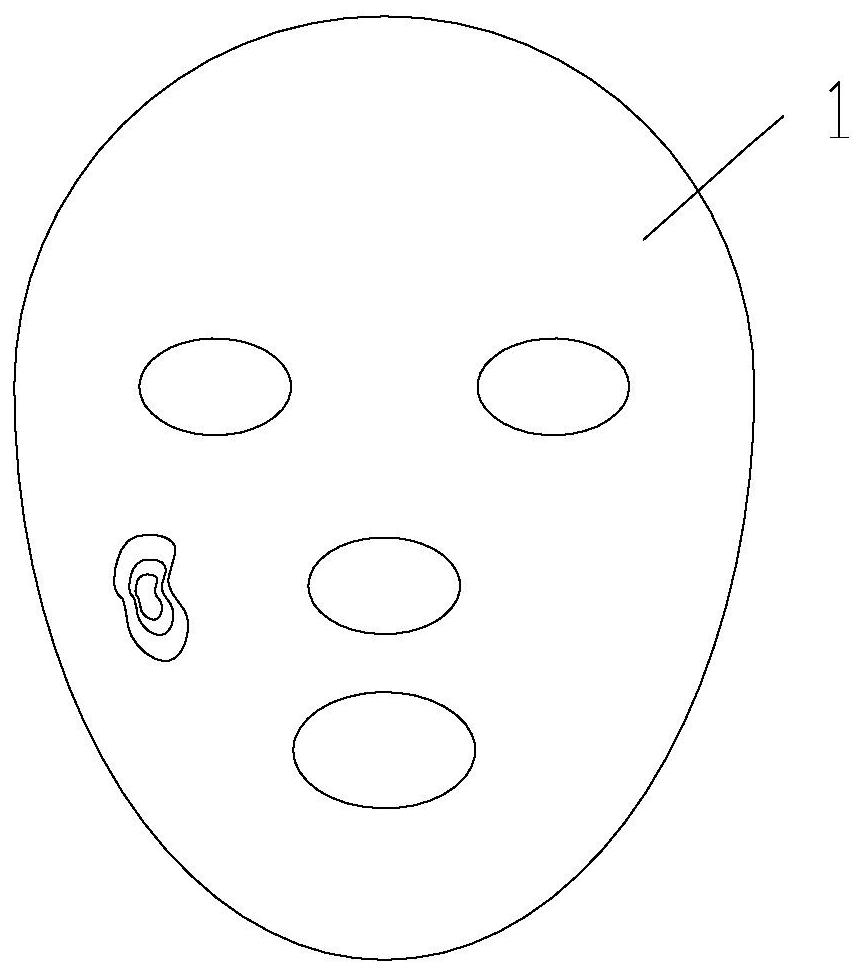

[0036] Such as Figure 1 to Figure 3 Shown is an embodiment of the silicone-coated 3D printed burn pressure mask of the present invention, which is used to cover the face of a burn patient for pressure treatment of scars.

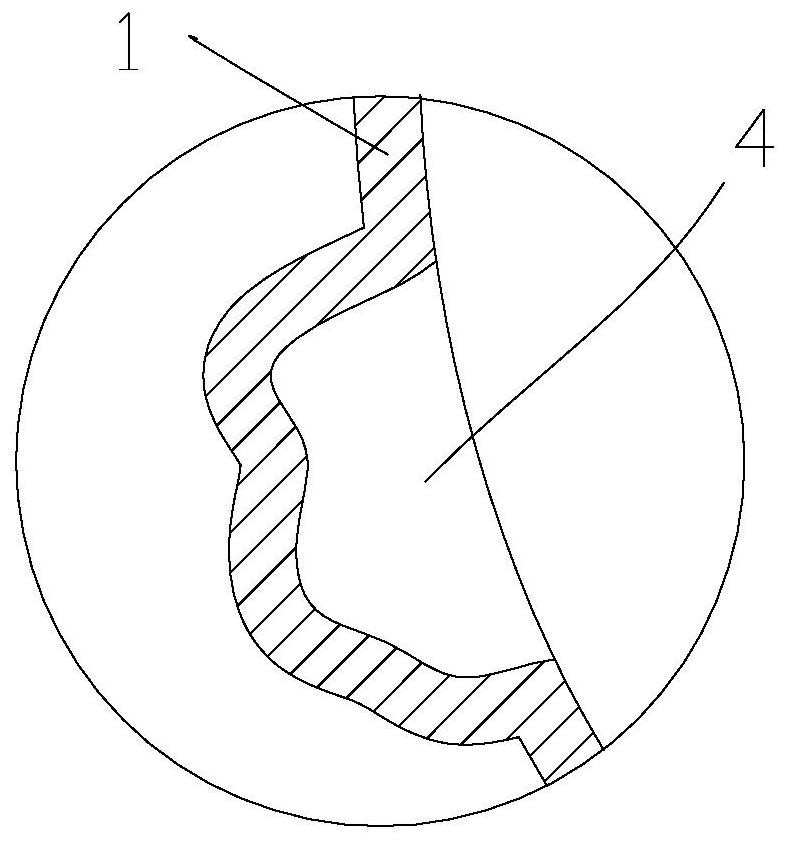

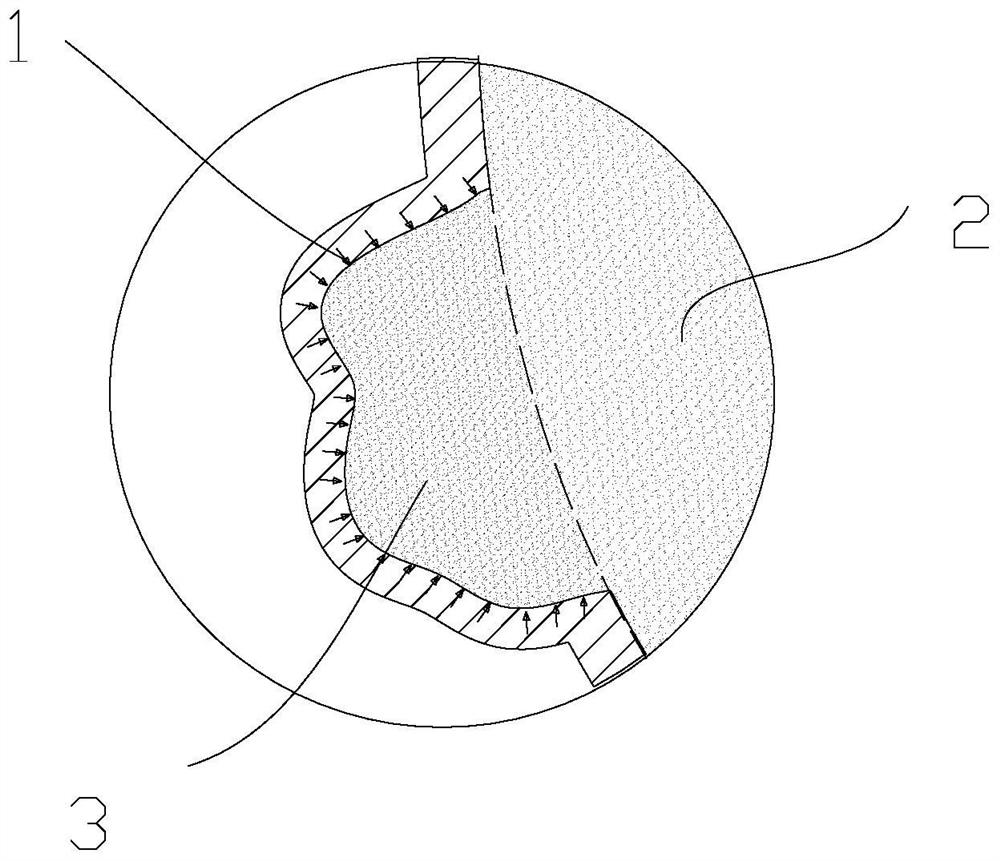

[0037] The material of the mask 1 is photosensitive resin, and the face of the mask facing the patient's face 2 is covered with a silicone coating and is provided with an indentation 4 corresponding to and smaller than the burn hypertrophic scar 3 of the burn patient. The indentation in this embodiment corresponds to and is uniformly smaller than Patients with burn hypertrophic scars. From figure 2 and image 3 It can be seen that the indentation 4 is smaller than the hypertrophic scar, so the mask at the indentation becomes thinner after wearing the patient's face, thus generating uniform pressure to point to the hypertrophic scar, as shown by the small arrow.

[0038] Of course, the indentation 4 is not necessarily uniformly smaller since it is smalle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com