Automatic film pasting equipment for steel sheet connecting line blanking

A film-attaching equipment and connection technology, which is applied in the field of automatic film-attaching equipment for steel sheet line blanking, can solve the problems of high cost, manual use, and inability to meet the production needs of enterprises, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the object, technical solution and advantages of the present invention more clear and definite, the present invention will be further described in detail below with reference to the accompanying drawings.

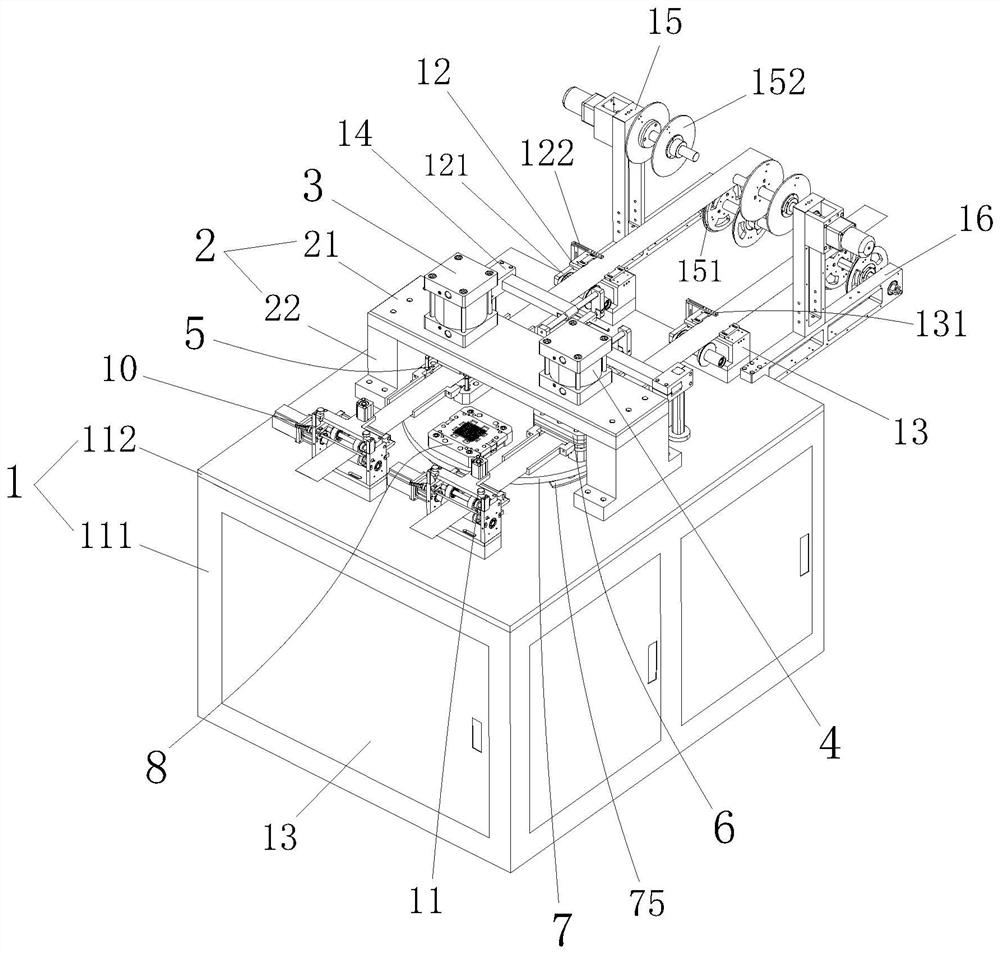

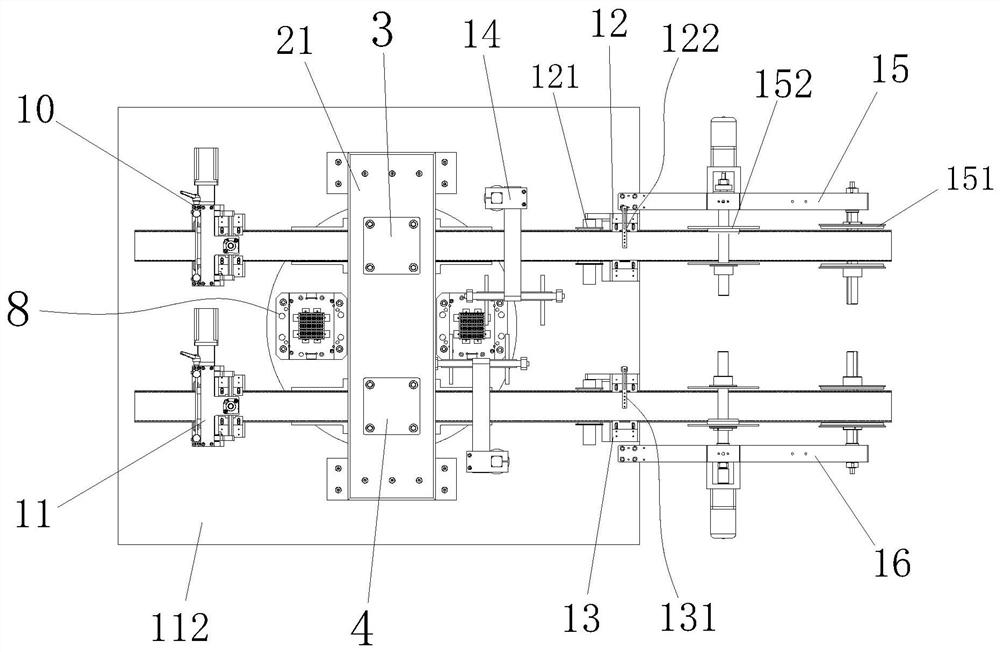

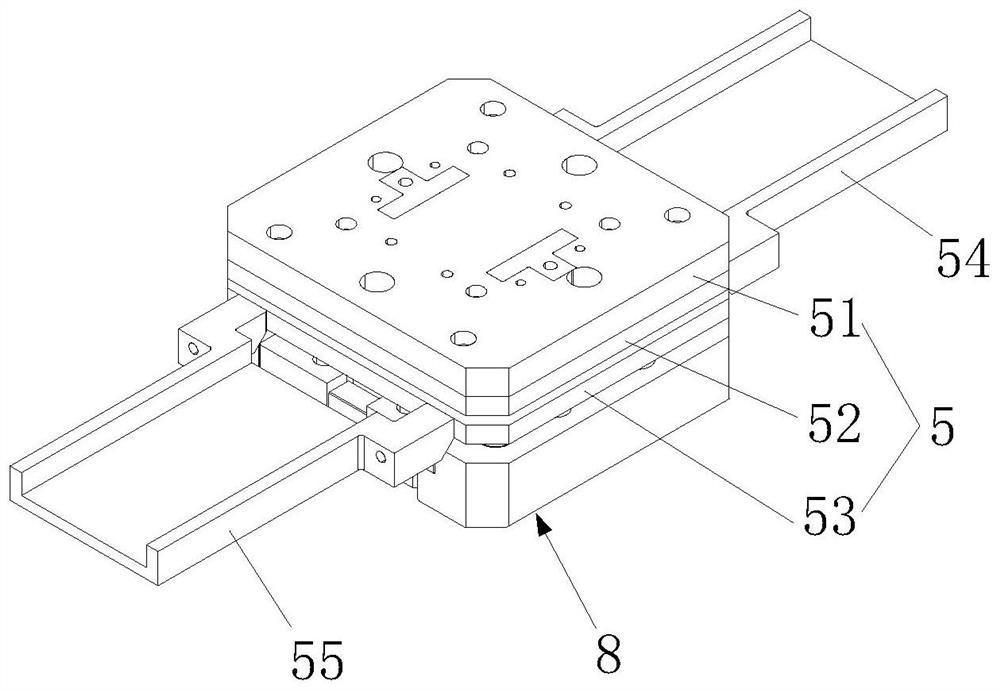

[0032] refer to Figure 1 to Figure 8 As shown, a steel sheet line blanking automatic film laminating equipment provided by the present invention includes: a machine 1, a bracket 2, a first driving device 3, a second driving device 4, a first upper die set 5, a second upper Module 6, turntable 7, lower mold group 8, ejector device 9, control module, first material pulling device 10, second material pulling device 11, first material guide block 12 and second material guide block 13.

[0033] refer to figure 1 , Figure 5 As shown, the machine platform 1 includes a frame body 111 and a workbench 112 arranged on the top of the frame body 111. The workbench 112 is provided with a first workbench through hole 1121 and four second workbench through holes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com