Supporting vehicle for constructional engineering construction

A technology for construction engineering and support vehicles, which is applied to support components, trolleys, motor vehicles, etc., and can solve the problems of inability to fully realize material unloading activities and manual unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

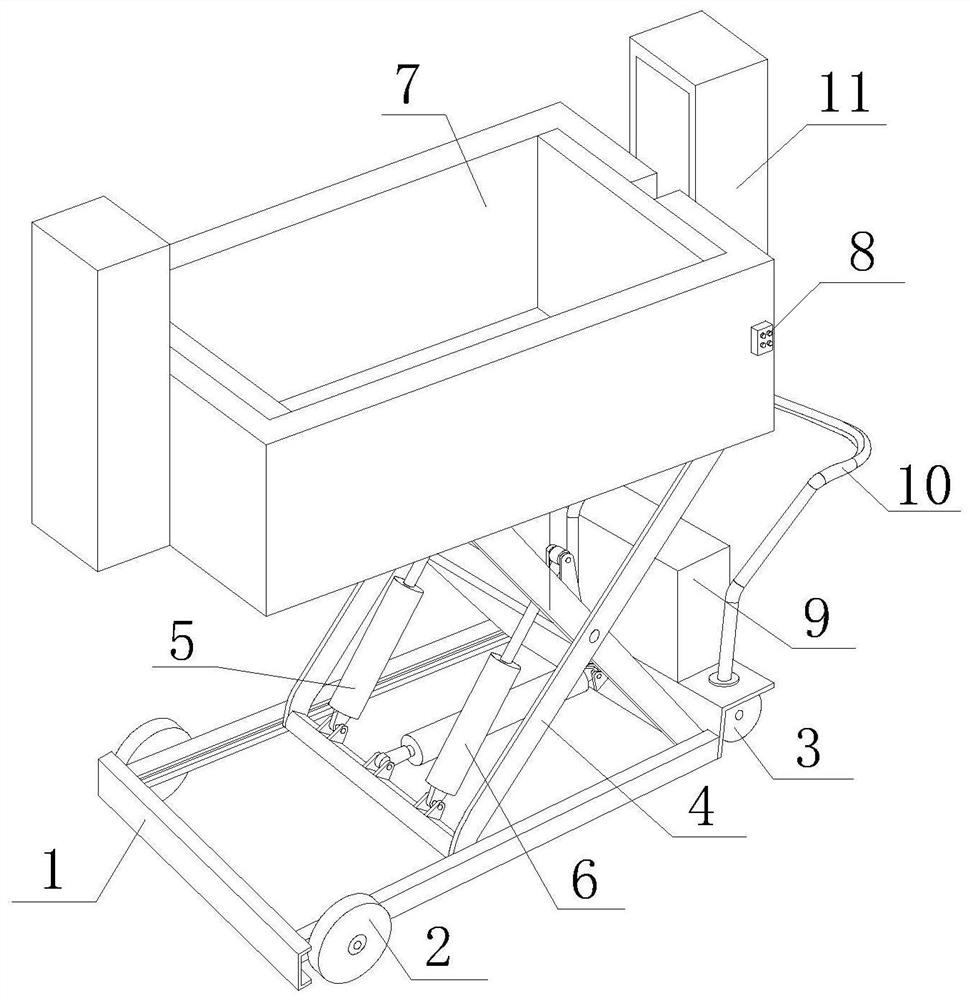

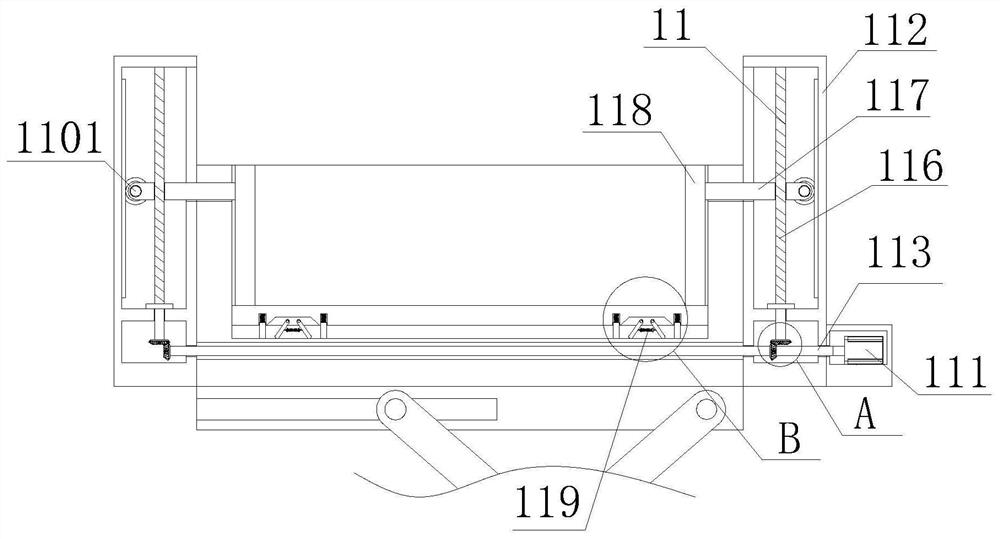

[0030] see figure 1 , the present invention provides a kind of support vehicle for building engineering construction through improvement, including an underframe 1 and a pushing device 11, front wheels 2 are rotatably connected to the front and rear ends of the left side of the underframe 1, and front wheels 2 are connected to the front and rear sides of the right side of the underframe 1. Both ends are provided with universal wheels 3, and the inner middle part of the bottom frame 1 is provided with a lifting frame 4, and the front and rear ends of the left side of the lifting frame 4 are rotatably connected to the first hydraulic cylinder 5, and the left middle part of the lifting frame 4 is rotatably connected to a second hydraulic cylinder. Hydraulic cylinder 6, the upper end of the right side of the first hydraulic cylinder 5 is rotatably connected with the lifting frame 4, the right side of the second hydraulic cylinder 6 is rotatably connected with the bottom frame 1, th...

Embodiment 2

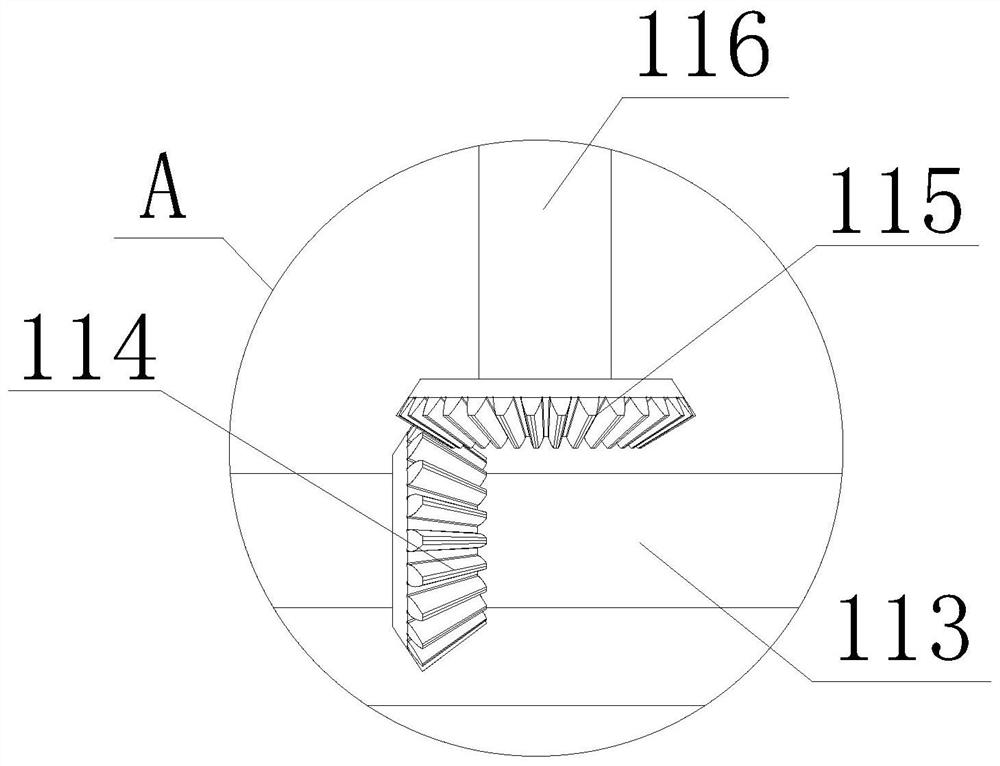

[0035] The present invention provides a kind of support vehicle for building engineering construction through improvement, the left and right sides of the pushing plate 118 are provided with the same length as the length of the left and right sides of the placement box 7, and the thickness of the bottom of the pushing plate 118 is 4CM, so that the pushing Material board 118 undertakes effect firmly, buffer board 1192 lower end and placement box 7 fit together, and buffer board 1192 can rotate angle to be 30 °, make through buffer board 1192 buffering and accepting effect, realize the strengthening of buffering protection to pusher board 118.

[0036] The present invention provides a kind of support vehicle for building engineering construction through improvement, and its working principle is as follows;

[0037] First, the material is placed inside the placement box 7, and then the support car is pushed to the designated position through the push handle 10 provided on the righ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com