Special lifter for large-scale cruise ship sheet segmented deck reverse side and lifter arrangement method

An arrangement method and technology of hanging horses, which are applied to the hull deck, load hanging elements, hull parts, etc., can solve the problems of segmental deformation, deformation, and hanging horse deformation of thin plates, and achieve easy installation, firm fixation, and steel plate saving. effect of material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

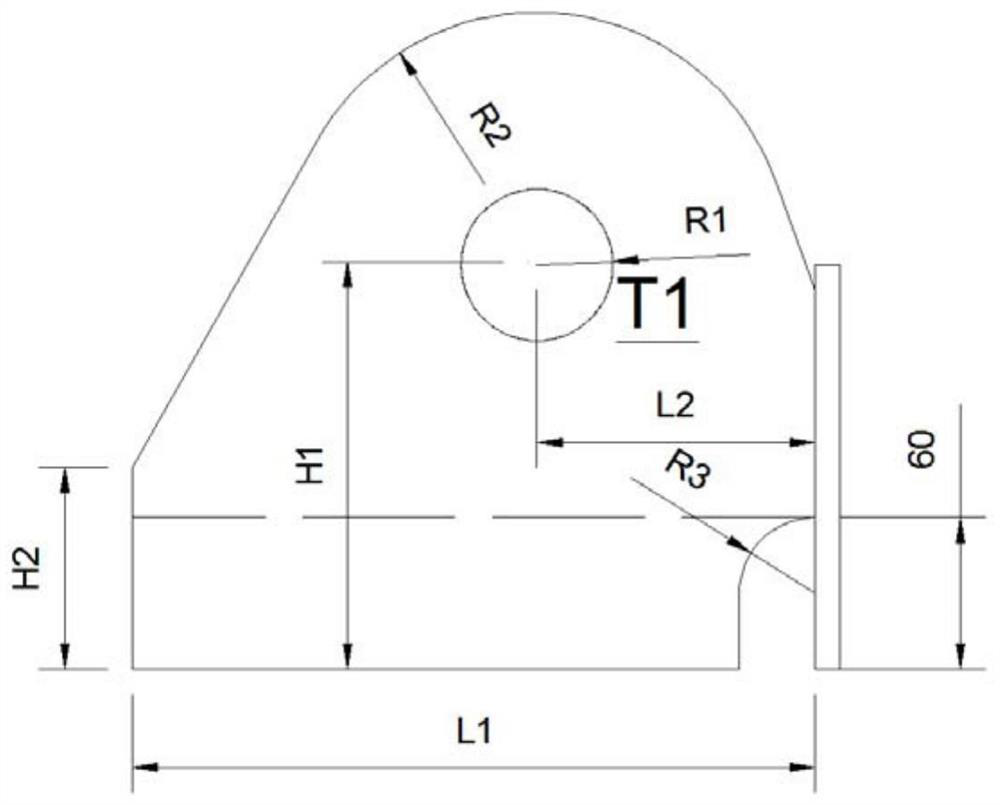

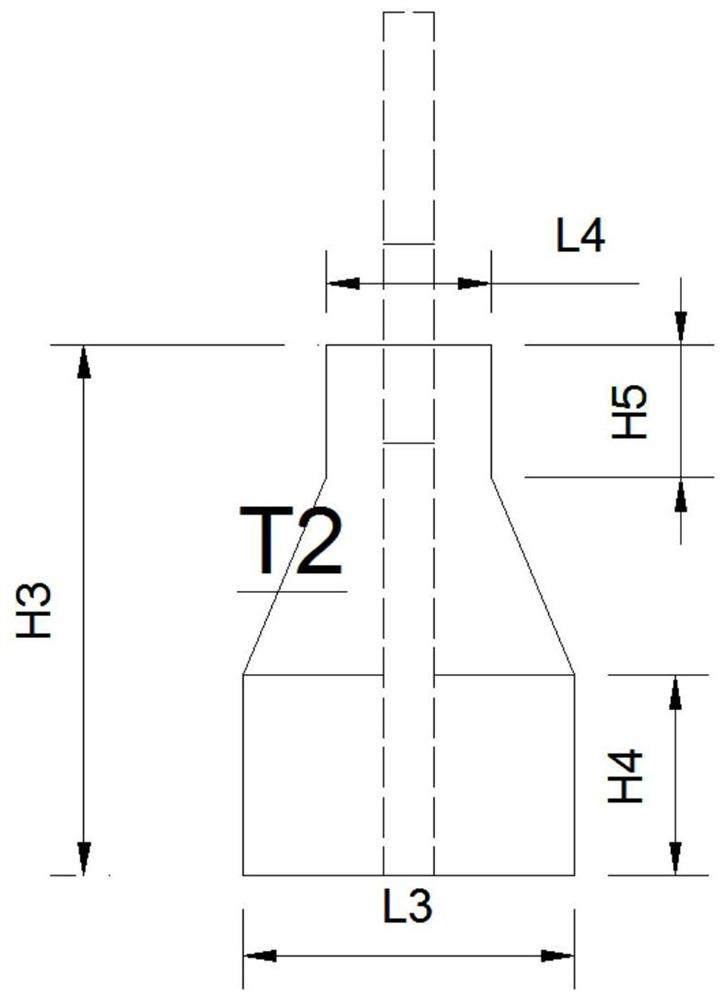

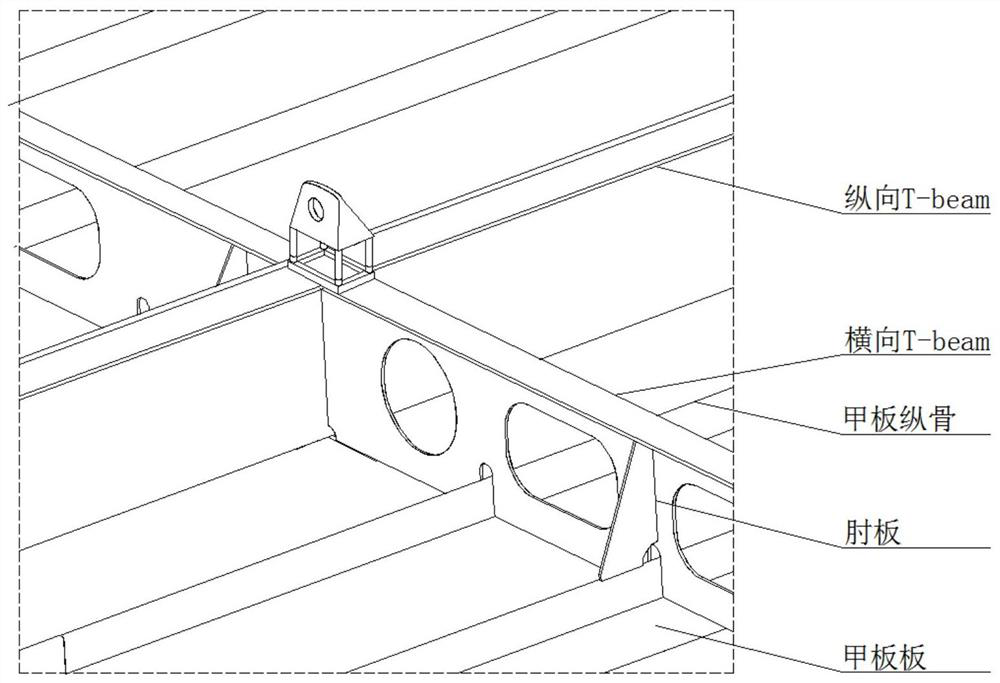

[0029] see Figure 1-8 , the present embodiment provides a special hoisting horse for the opposite side of the thin plate section deck of a large cruise ship, including a body 1, a fixing plate 3 is connected to the bottom of the body 1 through a steel wire rope 2, and an inner opening 4 is opened inside the fixing plate 3.

[0030] Wherein, when in use, welding is carried out on the bottom surface of the fixed plate 3, and the fixed plate 3 is arranged, and the body 1 of the hanging horse is connected above the fixed plate 3 through the wire rope 2; , when the fixed plate 3 is arranged, the outer surface of the fixed plate 3 and the inner surface of the inner port 4 are welded and connected, so that there are more solder joints on the fixed plate 3, so that the welding area of the fixed plate 3 is larger, and the The fixing of the fixing plate 3 is more firm, and this design facilitates the fixing of the fixing plate 3 and facilitates the removal of the fixing plate 3; wher...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com