Air inlet window

A technology of air inlet windows and windows, applied in the field of air inlet windows, can solve the problems of air leakage of air inlet windows, thicker anti-bird nets, and inability to bolt connection, etc., to achieve good overall performance, avoid relative deformation, and have a remarkable sealing effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

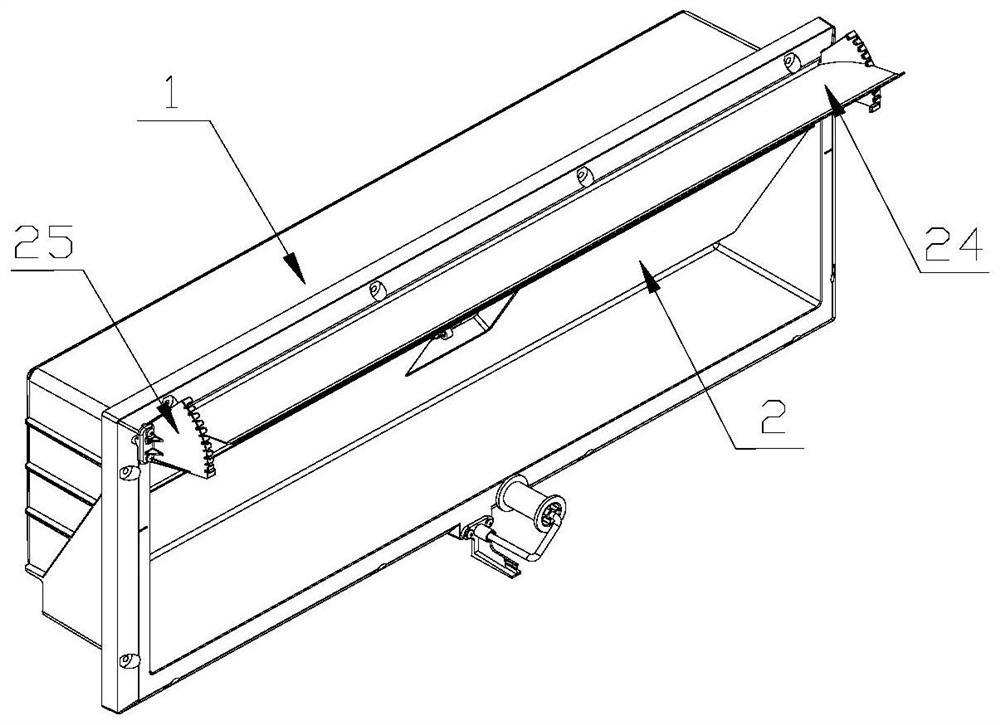

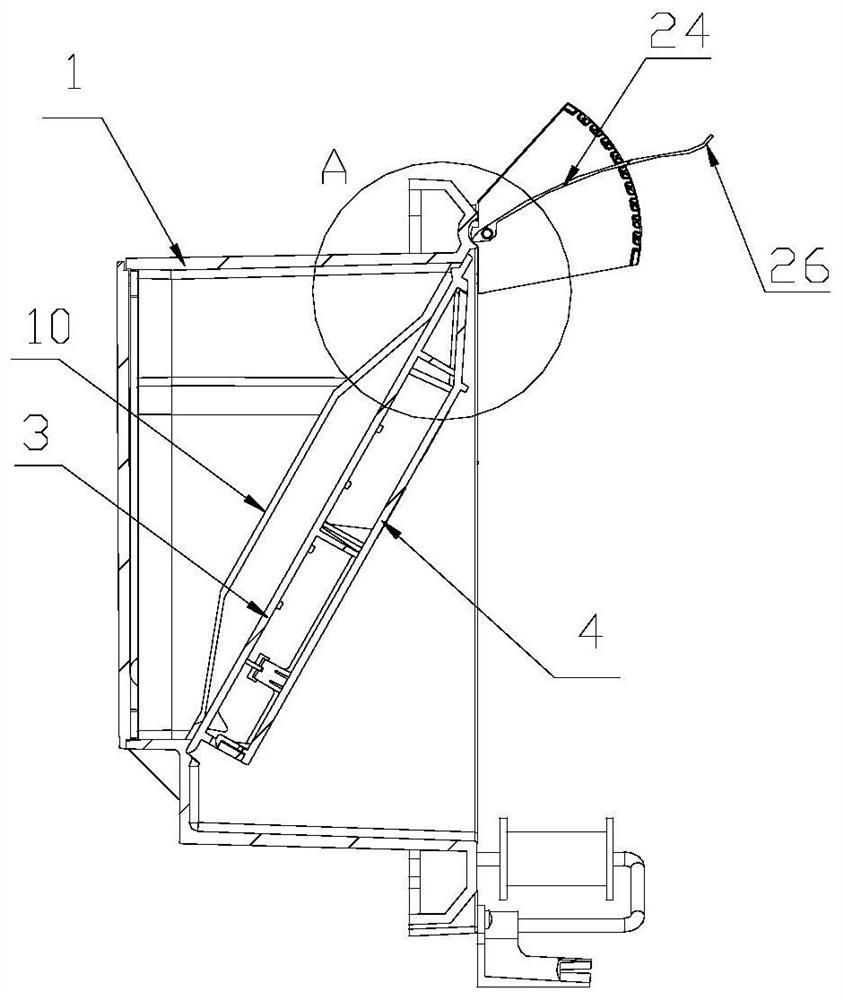

[0049] like figure 1 As shown, a wind inlet window includes a window 1 and a door panel 2, wherein the bottom of the door panel 2 is rotatably connected to the window 1, and its top is connected to the transmission assembly to realize free opening and closing and control the ventilation area. To achieve the purpose of indoor ventilation.

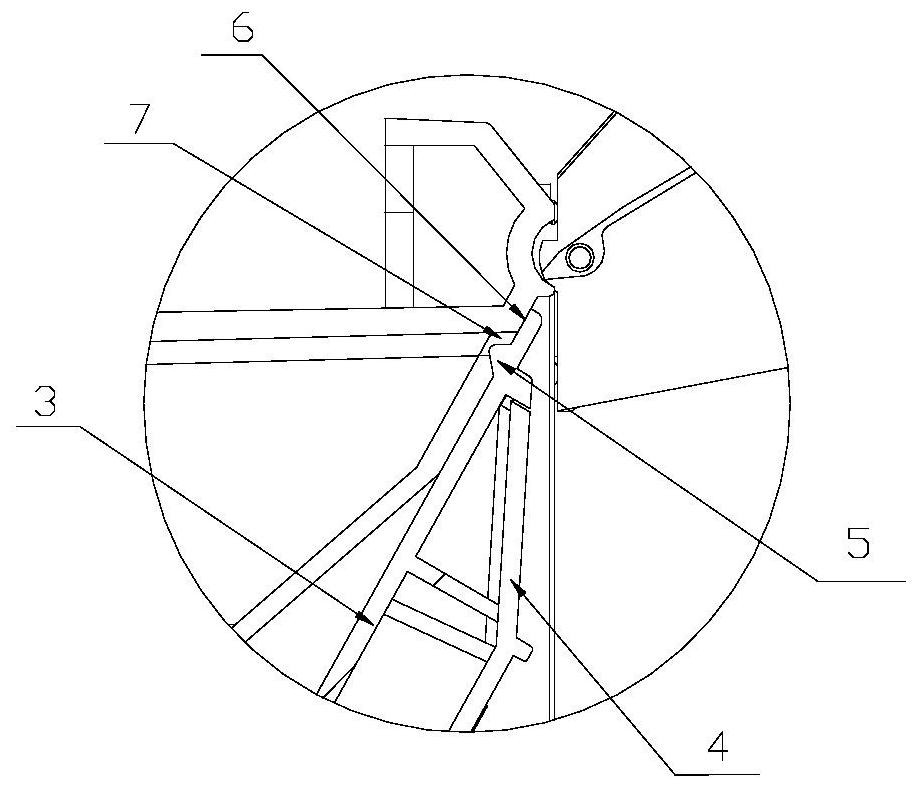

[0050] like Figure 1 to Figure 4 As shown, the door panel 2 includes an inner cover plate 3 and an outer cover plate 4, and the inner surface of the window 1 is provided with a sealing plate 8, that is to say, there are 2 sealing plates 8, and 2 sealing plates 8 are respectively located on the left side and the right side of Form 1. One side of the sealing plate 8 is set as an inclined surface 9, specifically, the side of the sealing plate 8 close to the door panel 2 is set as an inclined surface. At the same time, there is a gap 7 between the top of the sealing plate 8 and the window 1 , and correspondingly, the inner cover 3 is provide...

Embodiment 2

[0053] like figure 2 , Figure 5 to Figure 9 As shown, the inner cover 3 and the outer cover 4 are connected by buckles 12, and the buckles 12 are located on the outer cover 4, and a through hole 16 is opened on the inner cover 3 corresponding to the buckles 12, That is to say, through the synergistic effect of the buckles 12 and the through holes 16, the inner cover 3 and the outer cover 4 are integrated, and at the same time, the buckles 12 are evenly distributed on the surface of the outer cover 4, that is, There are multiple buckles 12 to further improve the integrity and stability of the door panel 2 and avoid problems such as relative deformation of the inner cover 3 and the outer cover 4 .

[0054] The buckle 12 includes an integrally formed connection end 14 and a first inverted claw 15, the connection end 14 is fixedly connected to the outer cover 4, and at the same time, a supporting rib is provided between the outer cover 4 and the connection end 14 13. Improve t...

Embodiment 3

[0057] like Figure 4 , Figure 10 to Figure 12 As shown, the inside of the window 1 and the outside of the inner cover 3 are provided with an anti-bird net 11, and the anti-bird net 11 is grid-shaped or mesh-shaped, which can effectively prevent outside birds from entering the room.

[0058] The anti-bird net 11 is provided with a plurality of inverted claw locks 19 for connecting the anti-bird net 11 and the window 1. At the same time, there are at least two inverted claw locks 19 to improve the anti-bird net 11 and the window. Connection stability of Form 1. Preferably, a plurality of inverted claw locks 19 are evenly distributed on the anti-bird net 11 . The window 1 is provided with a mounting sleeve 22 corresponding to the inverted claw lock 19, one end of the inverted claw lock 19 is fixedly connected to the bird-proof net 11, and the other end is at least two branches 20 arranged at intervals, and at least The end of one branch 20 is provided with a second inverted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com