A gas hydrate and oil and gas production well discharge plugging removal device

A technology for oil, natural gas and hydrate, which is applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc. It can solve the problems of filter tube hole clogging, poor oil (gas) flow, sand and mud production in production layers, etc. , to achieve the effect of eliminating hole blockage, simple and reliable system structure, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

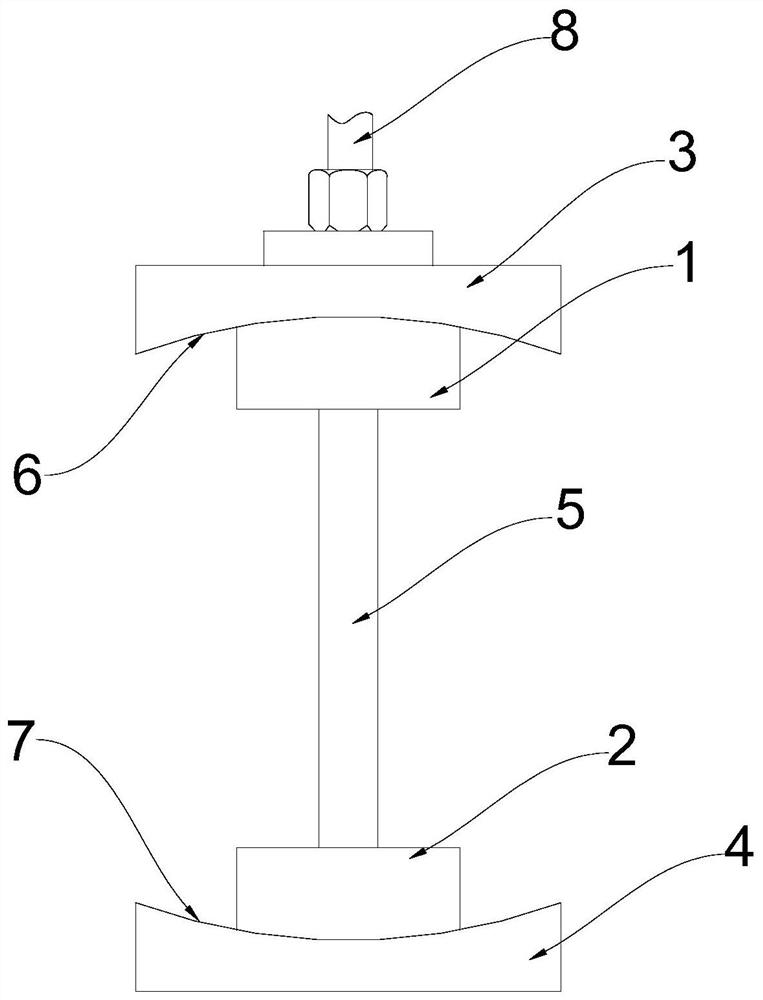

[0021] Please refer to figure 1 , the embodiment of the present invention provides a natural gas hydrate and oil and gas production well discharge plugging removal device, including an upper insulating flange 1, a lower insulating flange 2, a discharge electrode 5, an upper insulating reflector 3 and a lower insulating reflector4.

[0022] Specifically, the upper insulating flange 1 and the lower insulating flange 2 have the same structure and are arranged opposite to each other up and down, and the upper insulating flange 1 is located above the lower insulating flange 2 .

[0023] The discharge electrode 5 is arranged between the upper insulating flange 1 and the lower insulating flange 2, and the upper end of the discharge electrode 5 is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com