Loader gearbox clutch engagement control method and system

A control method and clutch technology, applied in the direction of transmission control, mechanical equipment, components with teeth, etc., to avoid one-sidedness, improve the service life of the clutch, and achieve the effect of precise tracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

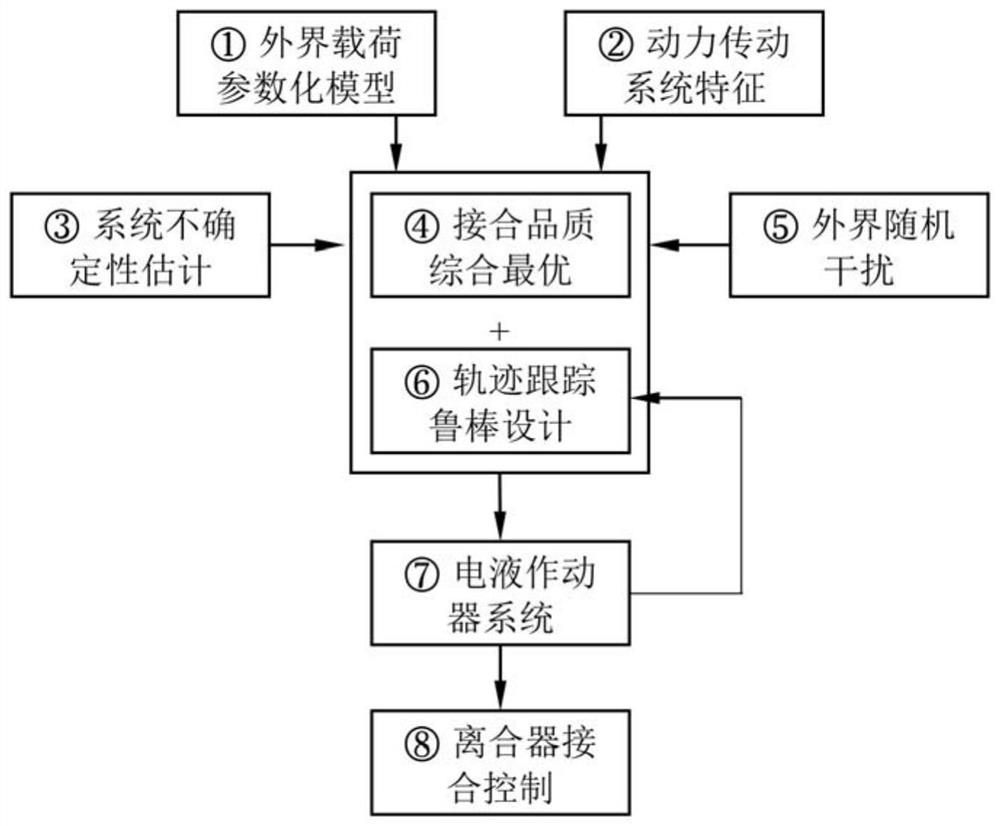

[0039] The clutch control method is to control the oil pressure to control the transmission of torque during the clutch engagement process. The torque transmission can be understood as the engagement torque trajectory, and the clutch engagement control oil pressure changes with time. The control oil pressure can be understood as the engagement pressure trajectory. Due to the lack of consideration of the load characteristics and external random disturbances in the actual engagement process, as well as the uncertainty estimation of the engagement system and changes in clutch characteristics, the torque variation during the clutch engagement process exceeds the control range, causing large fluctuations in the transmitted torque, resulting in clutch engagement. Increased process jitter produces a sense of frustration, making precise control impossib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com