Motion control method of cable robot and cable robot

A motion control and robot technology, applied in the motion control of cable robots, the field of cable robots, can solve problems such as cable surface damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

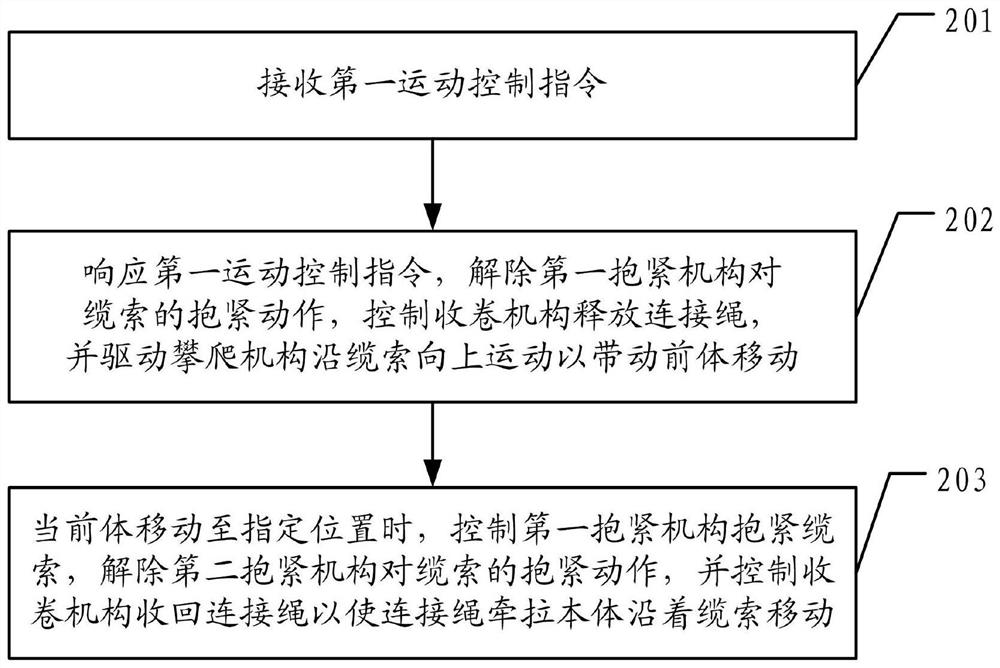

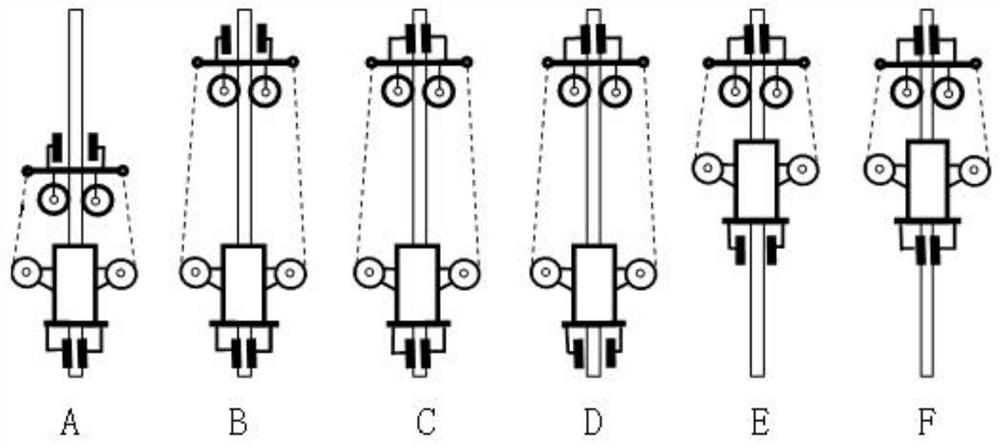

[0060] Embodiments of the present application provide a motion control method of a cable robot and the cable robot, so that the cable robot hardly causes damage to the cable during the movement process.

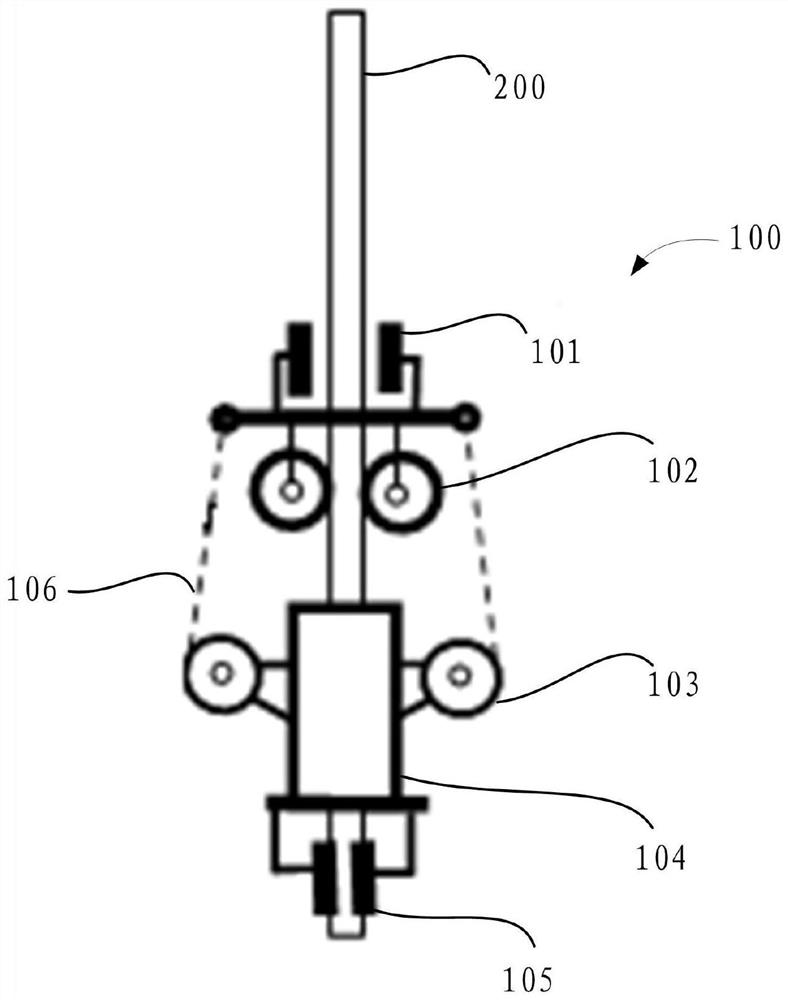

[0061] see figure 1 , the structural composition of the cable robot in the embodiment of the present application includes:

[0062] The front body, the winding mechanism 103 and the body, wherein the front body includes a first gripping mechanism 101 and a climbing mechanism 102, the body includes a second gripping mechanism 105 and a mechanism 104 for carrying a load, and the winding mechanism 103 is connected by A cord 106 connects the precursor to the body.

[0063] Wherein, the winding mechanism 103 can be arranged on the front body or on the main body. Preferably, the winding mechanism 103 is arranged on the body.

[0064] The climbing mechanism 102 may be a roller, or other mechanism capable of climbing on the cable 200 .

[0065] The first gripping mechanism 101 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com