Reciprocating type double-station integrated IC card packaging robot

A double-station, integrated technology, which is applied to record carriers, instruments, and computer components used in machines, can solve the problems of low integration, large equipment footprint, and long circulation path, and reduce the space occupied by volume , Compact structure, shortening the effect of circulation path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the implementation scope of the present invention is not limited thereto.

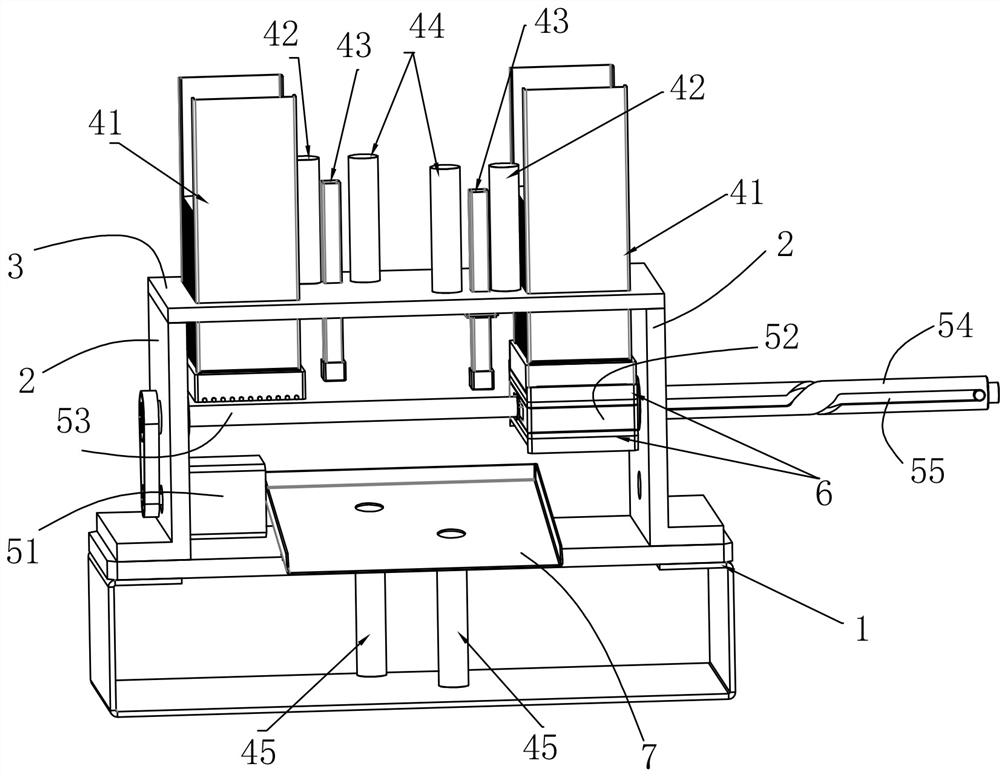

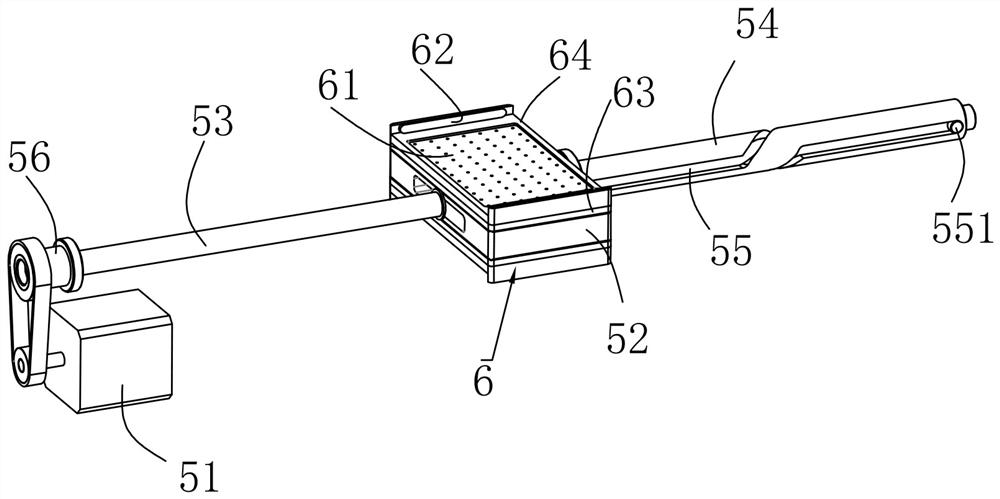

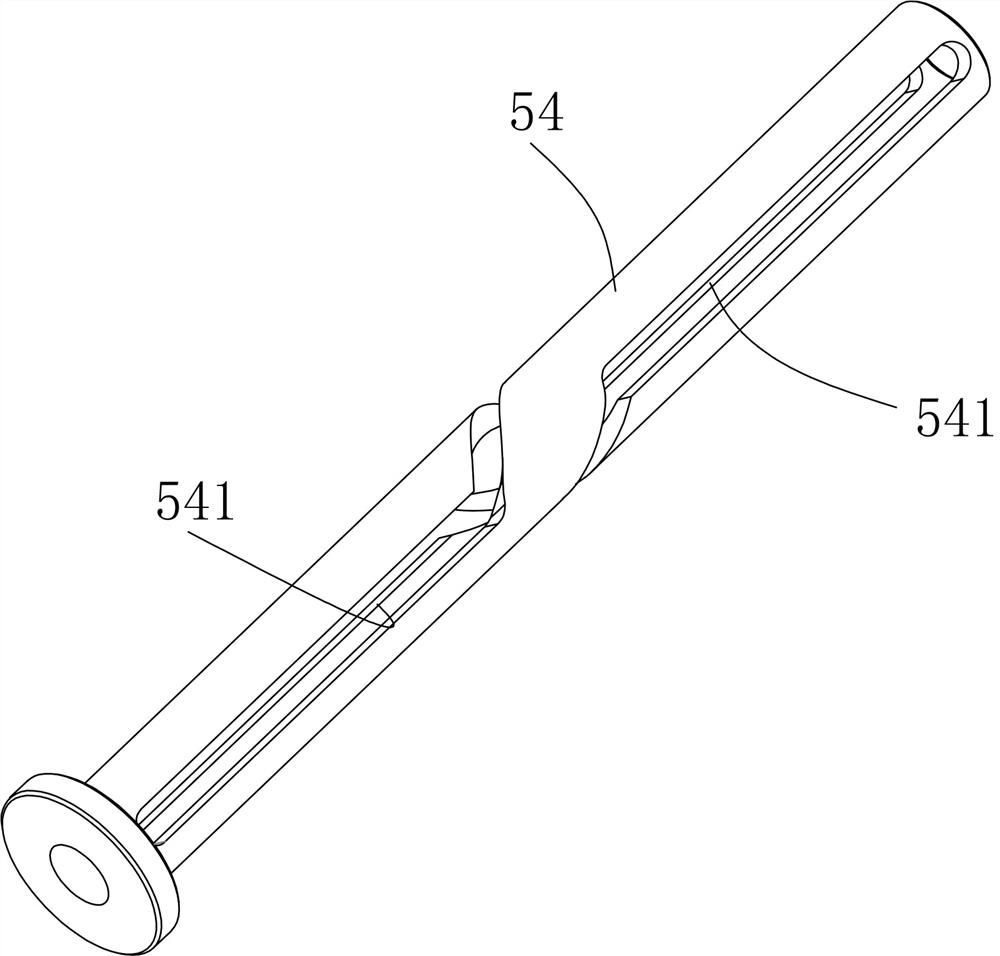

[0026] Such as Figure 1 to Figure 8 As shown, a reciprocating double-station integrated IC card packaging robot described in this embodiment includes a support base 1, two flipping support frames 2 symmetrically arranged on the support base 1, and two ends are fixedly connected to the two sides. The top plate 3 at the top of the flip support frame 2, the package assembly, the flip unit and the card vacuum carrier 6 arranged on the flip unit;

[0027] The packaging assembly includes a card placement unit 41, a glue injection unit 42, a chip placement unit 43, a heat press unit 44 and a cold press unit 45, and the card placement unit 41, the glue injection unit 42, the chip placement unit 43, and the heat press unit 44 is separately arranged on the top plate...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap