Spare power automatic switching device control system for electric power

A technology of device control and self-switching, which is applied in the direction of circuit devices, electrical components, emergency power supply arrangements, etc., can solve problems such as inconvenient practical use, generation of waste products, production stoppage, etc., and achieve the effect of being convenient for practical use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

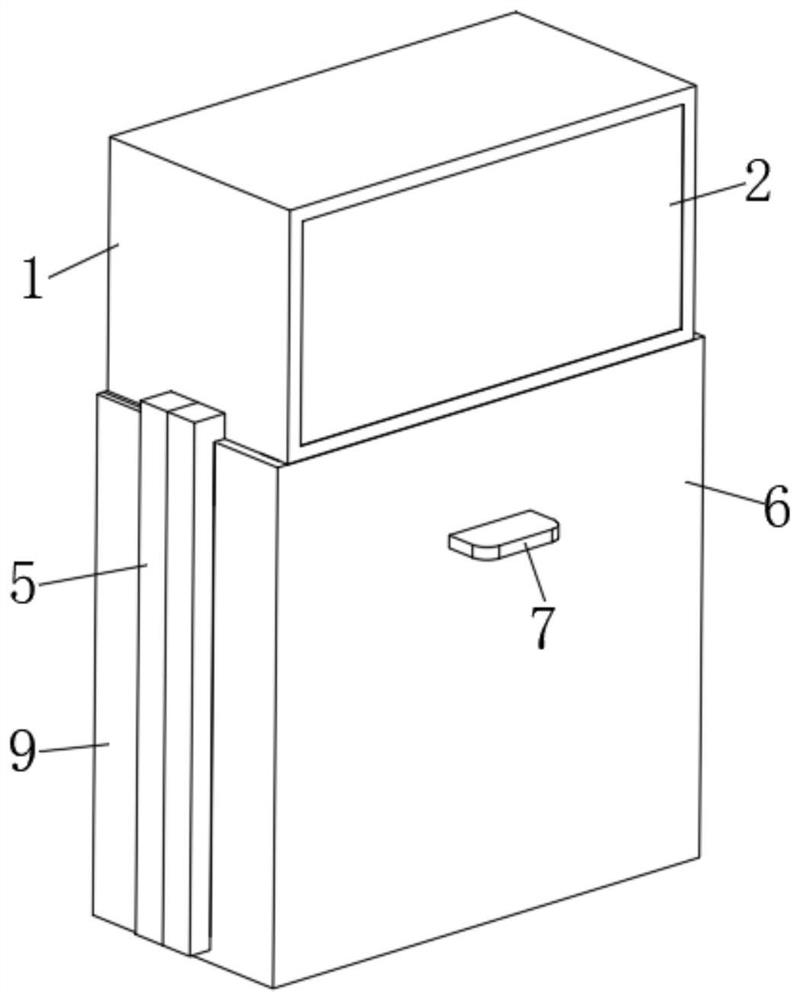

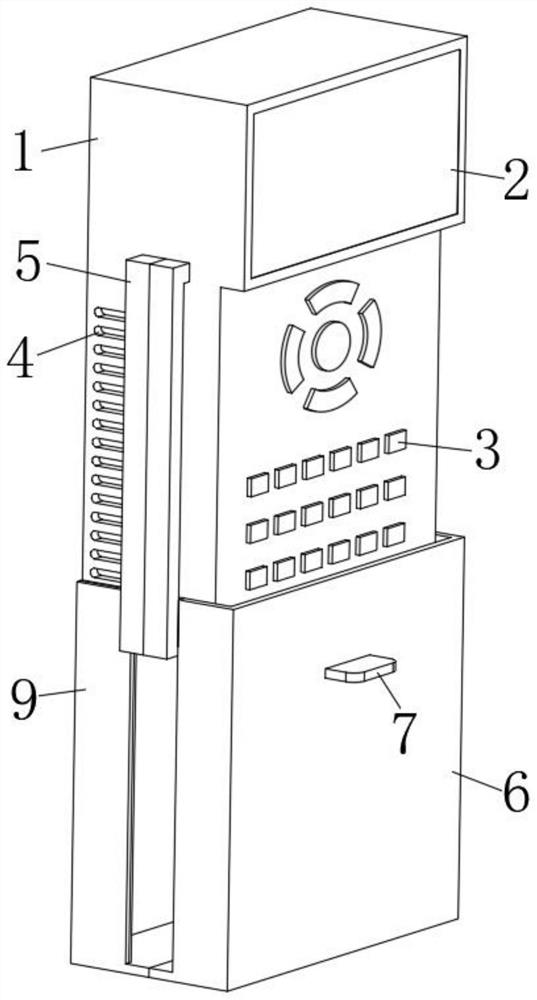

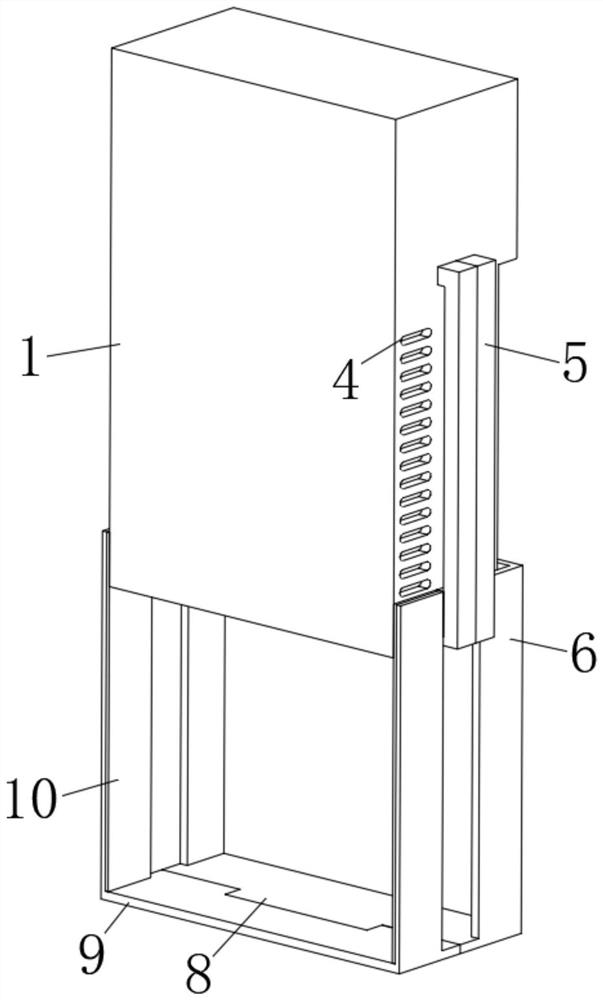

[0024] Such as Figure 1-6 As shown in the figure, a control system for self-injection device for electric power standby, it includes a device main body 1, a display screen 2 is arranged on one side of the device main body 1, a button 3 is arranged on one side of the device main body 1, and two sides of the device main body 1 are provided with There is a heat sink 4, and one side of the main body 1 of the device is fixedly connected with a sliding mechanism 5, and the number of the sliding mechanism 5 is two groups;

[0025] One side of the device main body 1 is movably connected with a protective cover 6 through one of the sliding mechanisms 5, one side of the protective cover 6 is fixedly connected with a pull block 7, and one side of the protective cover 6 is fixedly conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com