Data processing method of rolling mill equipment based on 5G network and related equipment

A technology of data processing and equipment, applied in the field of data processing, can solve the problems of high-frequency vibration data acquisition, transmission, diagnosis and analysis of rolling mills, etc., and achieve the effect of simplifying identification and management work and realizing transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

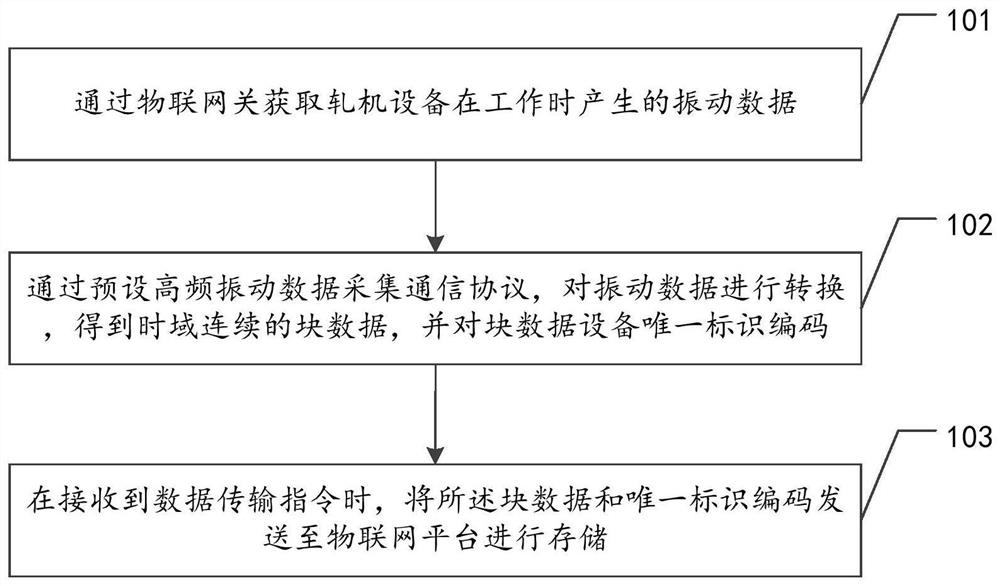

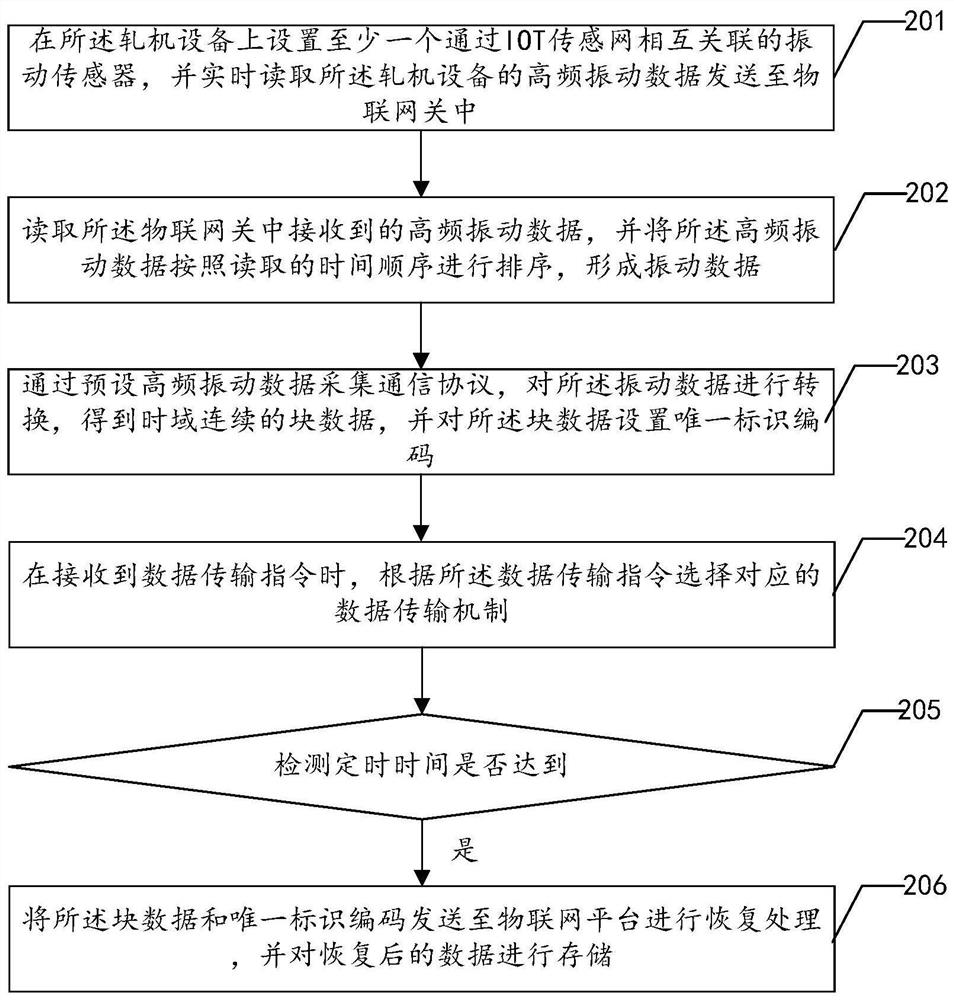

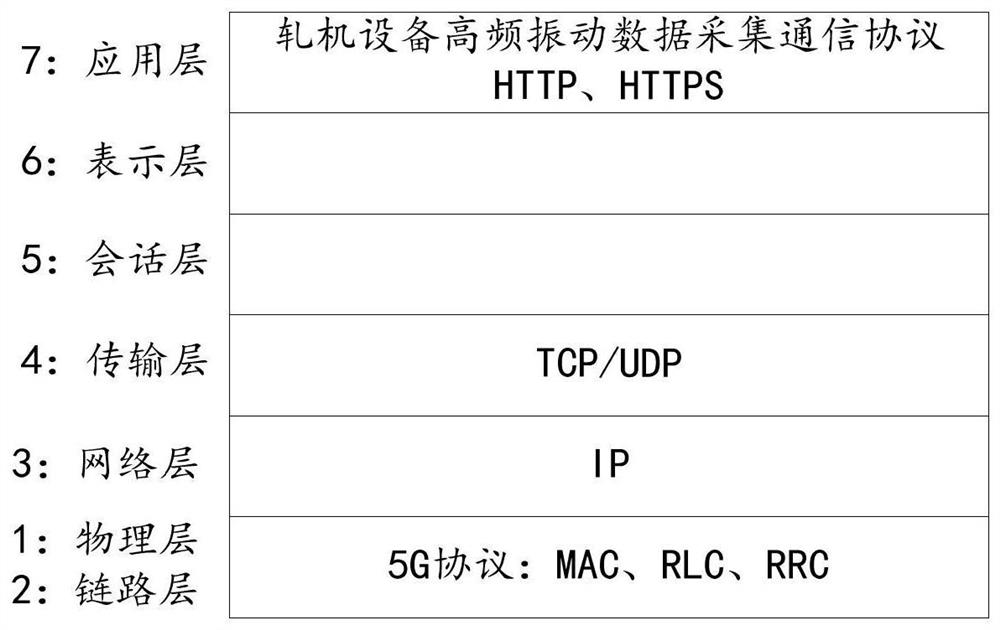

[0067] The embodiment of the present invention provides a data processing method of rolling mill equipment based on 5G network and related equipment. The high-frequency vibration data generated by the rolling mill equipment during operation is obtained through the gateway of the Internet of Things, and the high-frequency vibration data is collected by preset high-frequency vibration data. The communication protocol converts the vibration data to obtain continuous block data in the time domain, and sets a unique identification code for the block data, and sends the block data and the unique identification code to the object when receiving a data transmission instruction. The storage on the networking platform realizes the conversion of the vibration data communication protocol by deploying embedded vibration data protocol analysis on the IoT gateway under the 5G network environment of the rolling mill equipment, thereby realizing the transmission of continuous high-frequency vibr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com