Mixed heat energy tea leaf fixation machine capable of preventing leaves from being burnt

A greening machine and thermal energy technology, which is applied in the field of mixed thermal energy tea greening machine, can solve the problems of uneven heating of green leaves, large temperature gradient of the drum, and affecting the quality of greening, so as to achieve the point of not easy to burn leaves, uniform heating, and improve the quality of greening Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

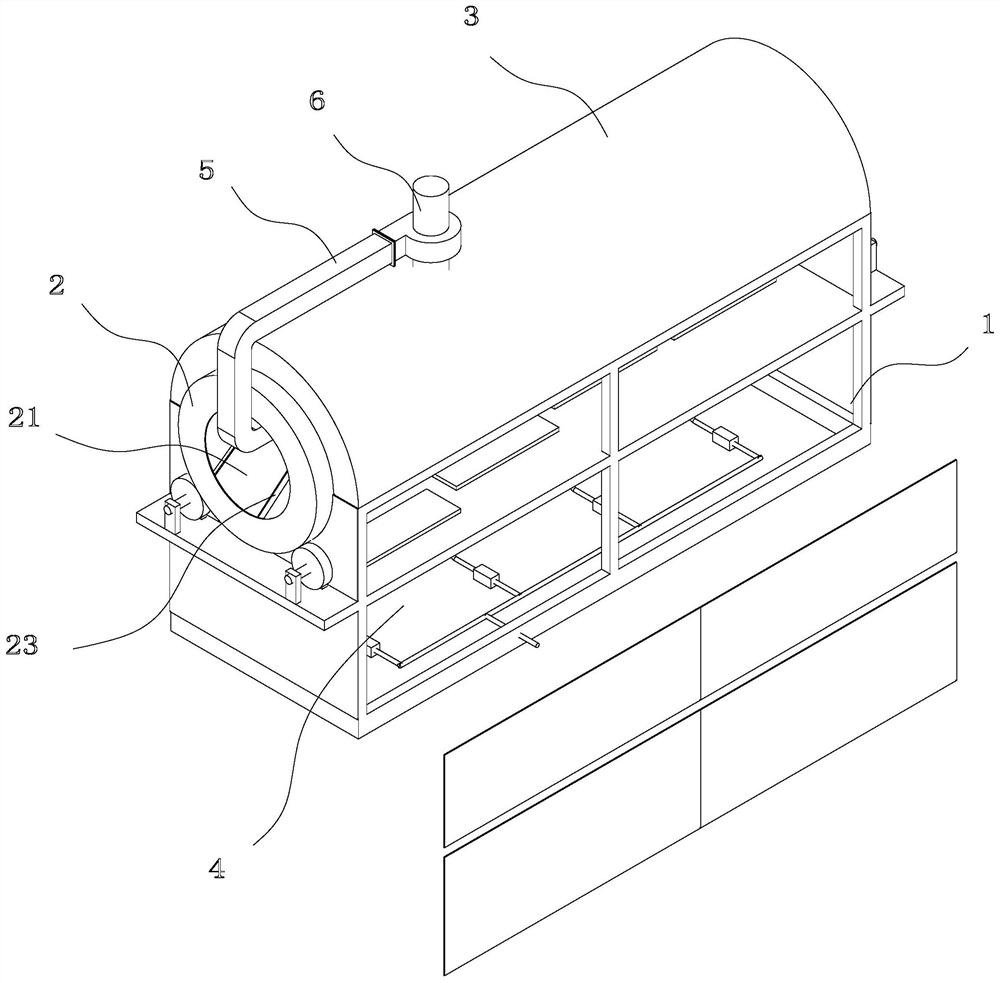

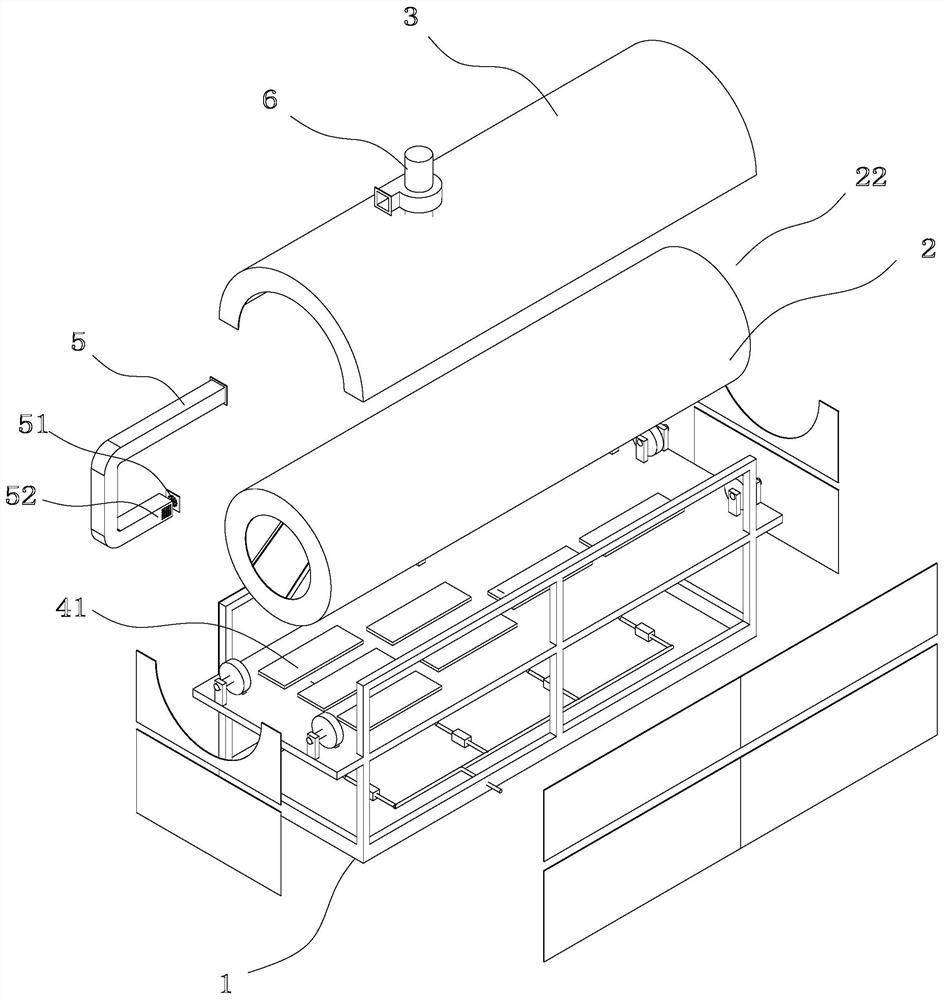

[0023] Embodiment 1: the mixed thermal energy tea greening machine that prevents scorched leaf of present embodiment 1, as figure 1 and figure 2 As shown, it includes a frame 1, a drum 2 placed on the frame, an outer cover 3, a transmission device, a heating device 4 and a controller. The inner wall of the drum is designed with a plurality of right-handed spiral guide vanes 22. The above-mentioned heating device includes a plurality of gas heating plates 41 located below the drum and distributed along the axis of the drum. The plurality of gas heating plates are equipped with independent gas proportional valves and Corresponding to the igniter, the gas proportional valve is externally connected to the gas storage tank through the gas pipeline, and multiple gas hot plates are distributed along the central axis of the drum to form multiple heating blocks, and the multiple heating blocks heat the outer surface of the drum in sections, among which There are four heating areas al...

Embodiment 2

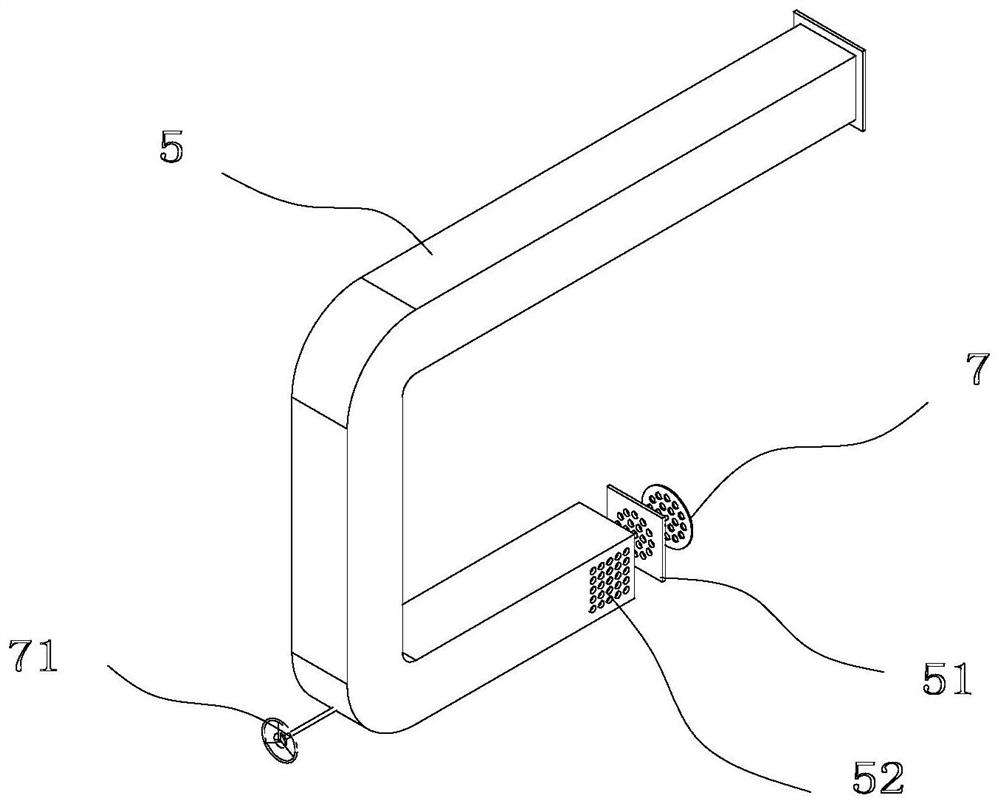

[0025] Embodiment 2: the mixed thermal energy tea greening machine that prevents scorched leaf of present embodiment 2, as image 3 As shown, a rotary damper plate 7 is also designed on the end plate of the hot air pipe. The above-mentioned rotary damper plate is designed with adjustment holes corresponding to the ventilation holes on the end face, and an adjustment rod 71 is fixed on the rotary damper plate. The axis of the adjusting rod coincides with the central axis of the above-mentioned hot air pipe. The adjusting rod passes through the above-mentioned horizontal hot air pipe and extends out of the drum. The operator can drive the rotation of the rotary damper plate through the adjusting rod according to the requirements of the finishing process, and then control the damper plate. The overlapping degree of the upper adjustment hole and the ventilation hole of the end plate adjusts the air volume and wind pressure of the end face of the hot air pipe accordingly, and a dial...

Embodiment 3

[0026] Embodiment 3: the mixed thermal energy tea greening machine that prevents scorched leaf of present embodiment 3, as Figure 4As shown, the end side pipe wall and the bottom pipe wall of the hot air pipe are also designed with a pull-out damper plate 8 respectively. Corresponding to the adjustment hole, a control rod 81 is fixed on the pull-out damper plate. The axis of the control rod is parallel to the axis of the above-mentioned hot air pipe. The control rod is close to the wall of the hot air pipe and extends to the outside of the drum. Pull the pull-out damper plate through the control rod, and then control the overlapping degree of the adjustment hole on the damper plate and the ventilation hole on the pipe wall, and adjust the air volume and air pressure of the side wall and bottom pipe wall of the hot air pipe accordingly. Scale lines can also be set on the wall, which can accurately display the pulling distance of the damper plate. The other parts of this embodi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap