A dedusting type hulling and polishing equipment for rice processing

A technology of rice processing and equipment, which is applied in the fields of application, grain finishing, and grain husking, etc. It can solve the problems of processing environment impact, inconvenient feeding and unloading material transportation, and affecting the appearance of rice, so as to reduce pollution and increase aesthetics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

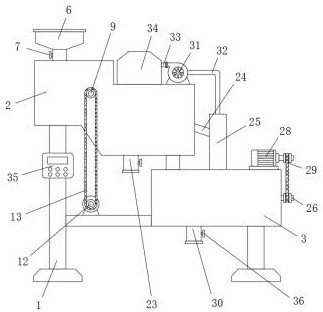

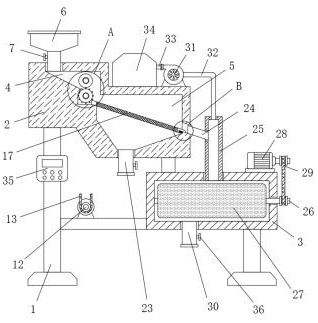

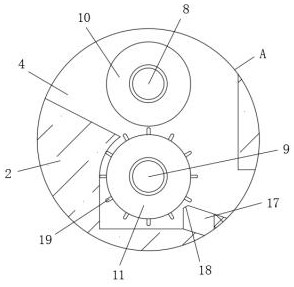

[0027] refer to Figure 1-7, a dust-removing type hulling and polishing equipment for rice processing, comprising a mounting frame 1, a shelling box 2 and a polishing box 3 are respectively fixedly installed on the mounting frame 1, the shelling box 2 is located obliquely above the polishing box 3, and The inside of the shell box 2 is respectively provided with a shelling chamber 4 and a screening chamber 5, and the shelling chamber 4 is located on the obliquely above the side of the screening chamber 5 away from the polishing box 3 and communicates with the screening chamber 5 One side of the top of the shelling box 2 is provided with a feed hopper 6 communicating with the shelling chamber 4, and one side of the feed hopper 6 is provided with a first solenoid valve 7, and the shelling chamber 4 is provided with a shelling chamber 4. Assemblies, the shelling chamber 4 and the screening chamber 5 are slidably connected with the same screen 17, and the screen 17 is matched with ...

Embodiment 2

[0029] Further improved on the basis of embodiment one:

[0030] In the present invention, the two ends of the second rotating rod 9 respectively extend to the outsides of both sides of the shelling box 2, and the first motor 12 positioned at the bottom of the shelling box 2 is fixedly installed on the mounting frame 1, and the output shaft of the first motor 12 The same first belt 13 is connected to one side of the second rotating rod 9 on the outside of the shelling box 2 , and the first motor 12 is started to provide power for the rotation of the second rotating rod 9 through the first belt 13 .

[0031] In the present invention, one side of the first rotating rod 8 extends to the outside of the shelling box 2 and is fixedly covered with a large pulley 14, and the second rotating rod 9 is positioned outside the shelling box 2 and fixed on the side away from the first belt 13. The small pulley 15 is sleeved, and the large pulley 14 and the small pulley 15 are driven and conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com