Inverted paper cutting machine with upward cutting edge

An inverted paper cutter technology, applied in the mechanical field, can solve problems such as uneven incisions and machine debris accumulation, and achieve the effects of solving uneven incisions, improving safety, and improving cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

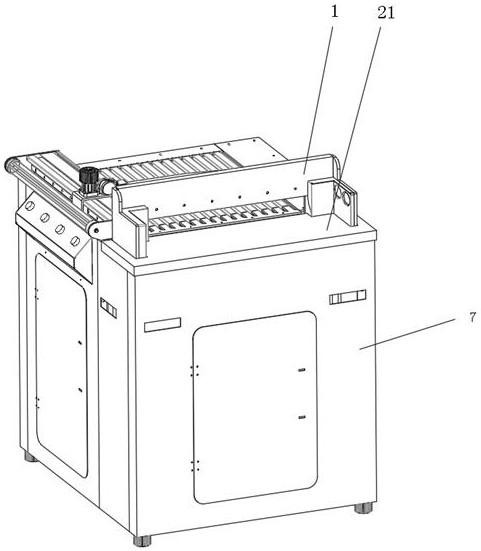

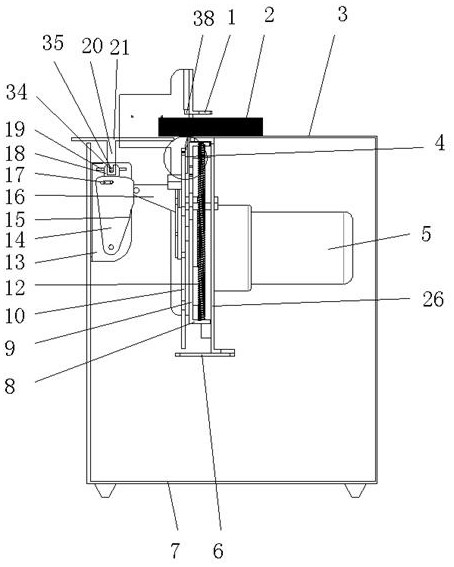

[0035] Such as Figure 1 to Figure 21 As shown, a paper cutter with an upside-down blade of the present invention includes a frame 7, a paper cutting mold 3, and a motor 5, and the paper cutting mold 3 is arranged on the top surface of the frame 7, wherein the frame 7 is provided with a paper pressing frame 9, and the paper pressing frame 9 is perpendicular to the paper cutting mold 3, and a power input shaft is arranged in the frame 7, and a cam 22 is fixedly arranged on the power input shaft, and a cutting machine is arranged in the frame 7. Knife driving mechanism and spring pressing mechanism,

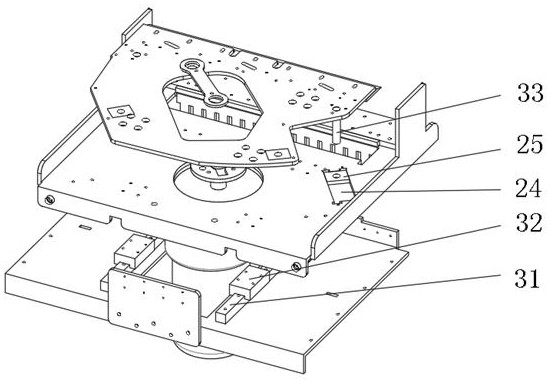

[0036] Described cutter driving mechanism comprises a connecting rod 23 and a knife rest 10, and knife rest 10 is arranged on one side of paper press frame 9 in parallel, and knife rest 10 upper end is fixedly connected with the cutting knife 4 that blade goes up, and paper press frame 9 An inclined chute 24 is respectively arranged on both sides of the top, and a first slide bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com