A corrugated electroplated diamond wire

A technology of electroplating diamond and corrugated shape, which is applied in the direction of metal sawing equipment, metal processing equipment, sawing machine tools, etc. It can solve the problems that diamond particles are easy to fall off and affect the service life, so as to achieve enhanced chip removal ability and eliminate line marks , the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

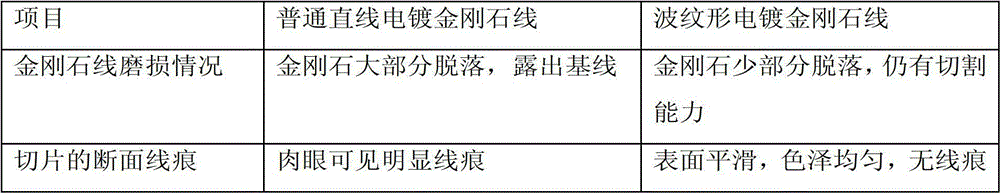

[0017] Select the corrugated shape is U-shaped, the peak height is 0.05 ~ 0.5mm, the wave pitch is 1 ~ 5mm, the metal embryo wire is 0.1mm in diameter, the diamond particle size is 10 ~ 20μm, and the corrugated electroplating method is prepared by composite electroplating method. The diamond wire is compared with the linear diamond wire prepared by the same wire diameter, the same diamond particle size, and the same process. On the same cutting machine, slice two polysilicon rods of the same size, the diameter of the polysilicon rod is 2″, and cut out 50 silicon wafers at the same time. After cutting, observe the wear condition of the diamond wire and the line marks of the sliced section, as shown in Table 1:

[0018] Table 1

[0019]

[0020] The service life of the corrugated electroplated diamond wire and the quality of the cut section are obviously better than that of the ordinary straight line electroplated diamond wire.

Embodiment 2

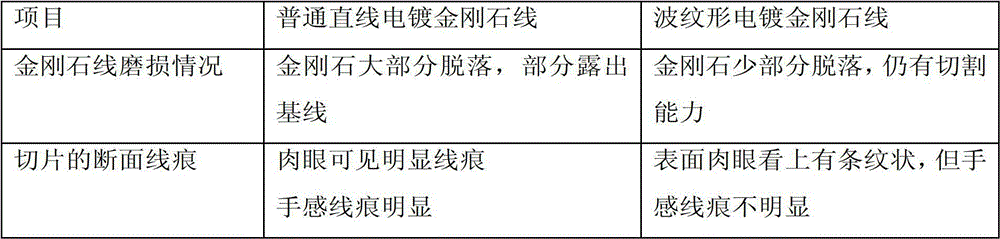

[0022] Choose a metal embryo wire with a V-shaped corrugation, a peak height of 1-1.5 mm, a wave pitch of 5-10 mm, and a wire diameter of 0.5 mm. The diamond particle size is 60-70 μm, and the corrugated electroplating method is prepared by composite electroplating. The diamond wire is compared with the linear diamond wire prepared by the same wire diameter, the same diamond particle size, and the same process. On the same cutting machine, slice two polysilicon rods of the same size, the diameter of the polysilicon rod is 2″, and cut out 50 silicon wafers at the same time. After cutting, observe the wear of the diamond wire and the line marks on the end face of the slice, as shown in Table 2:

[0023] Table 2

[0024]

[0025] The service life of the corrugated electroplated diamond wire and the quality of the cut section are obviously better than that of the ordinary straight line electroplated diamond wire.

Embodiment 3

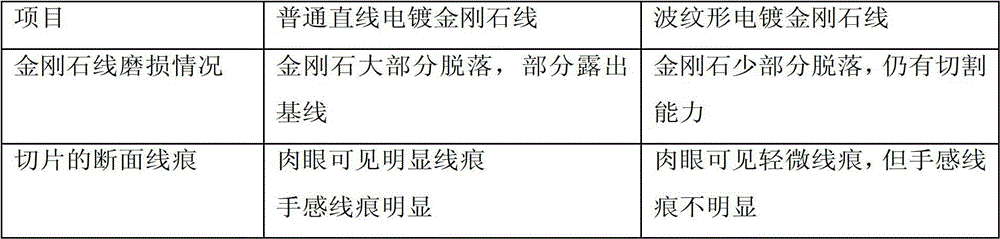

[0027] Choose a metal embryo wire with a V-shaped corrugation, a peak height of 2.5-3mm, a wave pitch of 10-15mm, and a wire diameter of 1.2mm. The diamond particle size is 130-150μm, and the corrugated electroplated diamond prepared by the composite electroplating method Wire, compared with the straight diamond wire prepared by the same wire diameter, the same diamond particle size, and the same process. On the same cutting machine, slice two polysilicon rods of the same size, the diameter of the polysilicon rod is 2″, and cut out 50 silicon wafers at the same time. After cutting, observe the wear condition of the diamond wire and the line marks of the sliced section, as shown in Table 3:

[0028] table 3

[0029]

[0030] The service life of the corrugated electroplated diamond wire and the quality of the cut section are obviously better than that of the ordinary straight line electroplated diamond wire.

[0031] It can be known from Tables 1, 2, and 3 that the servic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com