Deep hole machining device for production

A processing device and deep hole technology, applied in metal processing, etc., to achieve the effect of reducing cost, reducing severe vibration, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

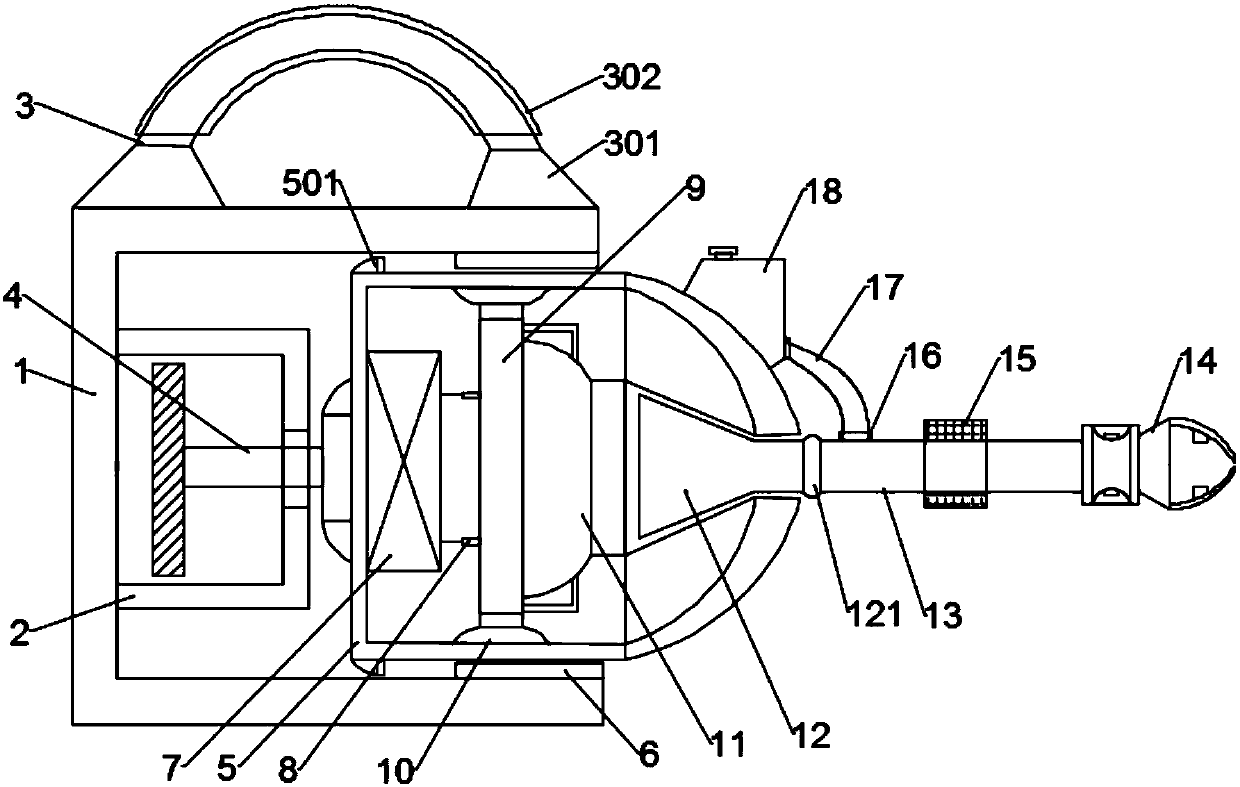

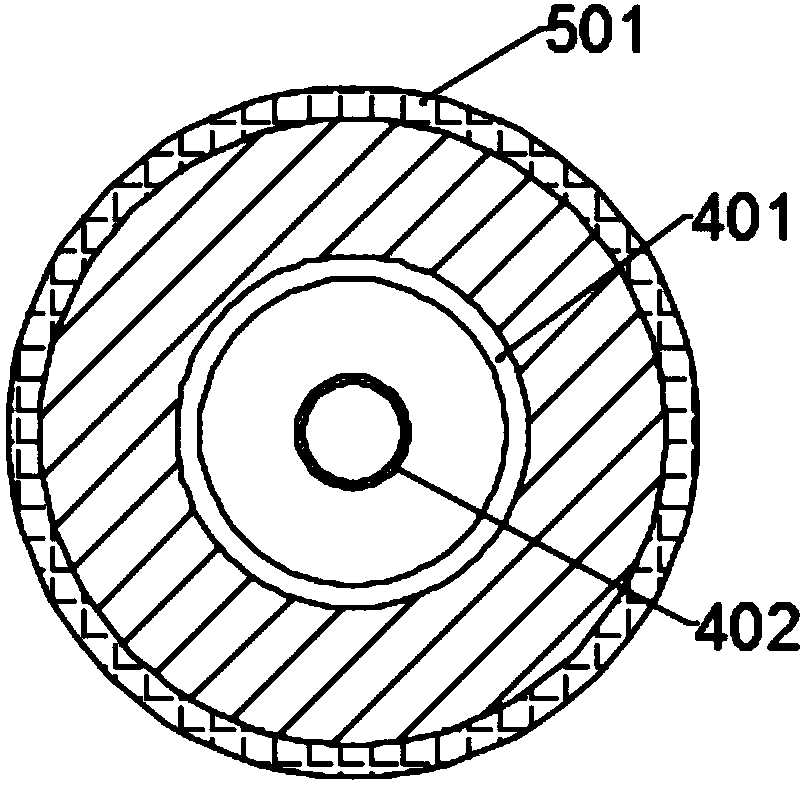

[0026] Such as figure 1 and figure 2 As shown, the present invention provides a deep hole processing device for production, including a device main frame 1, a hydraulic cylinder 2 is installed inside the device main frame 1, and a portable The handle 3, wherein the two ends of the portable handle 3 are fixedly installed on the outer surface of the device main frame 1 through the base plate 301, and the portable handle 3 is covered with a non-slip rubber sleeve 302, which is convenient for people to hold the deep hole Processing device, to carry out normal deep hole processing operations, the piston rod 4 of the hydraulic cylinder 2 is connected with an ultrasonic vibration box 5, and the top of the piston rod 4 is fixedly connected with the ultrasonic vibration box 5 through a mounting plate 401. The installation The disc 401 is a circular platform structure, and a rod hole 402 is provided in the middle of the mounting disc 401, and the rod hole 402 is connected with the pis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com