Intelligent Fault Detection Method for Air Braking Devices of Railway Freight Cars

A technology for air brakes and railway wagons, applied in the direction of brakes, brake components, brake safety systems, etc., can solve problems such as performance degradation, difficult failures, and inability to accurately reflect facts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

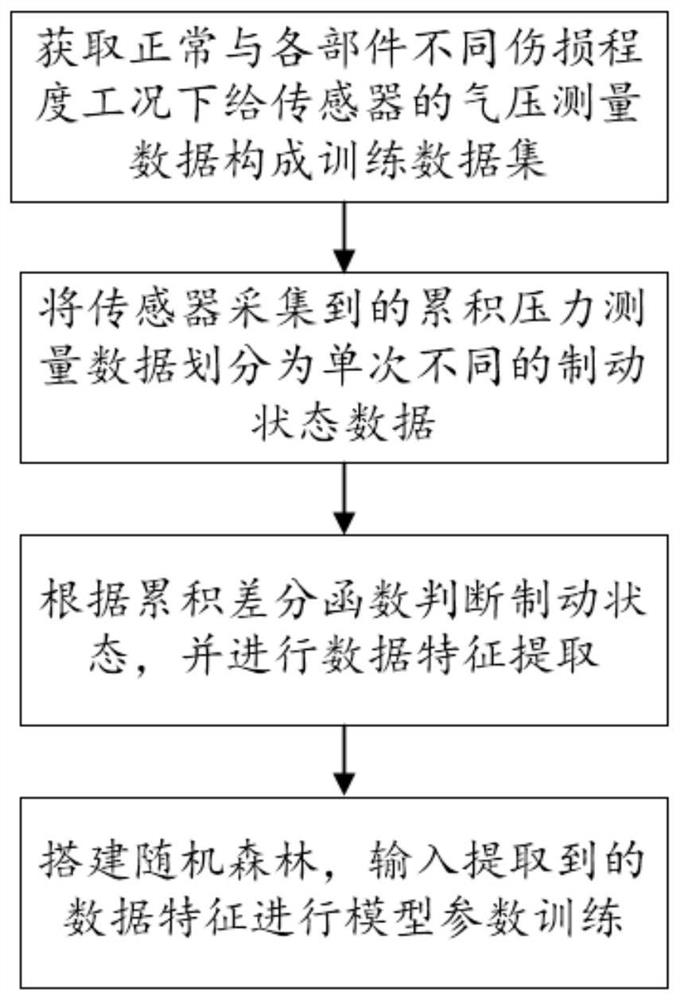

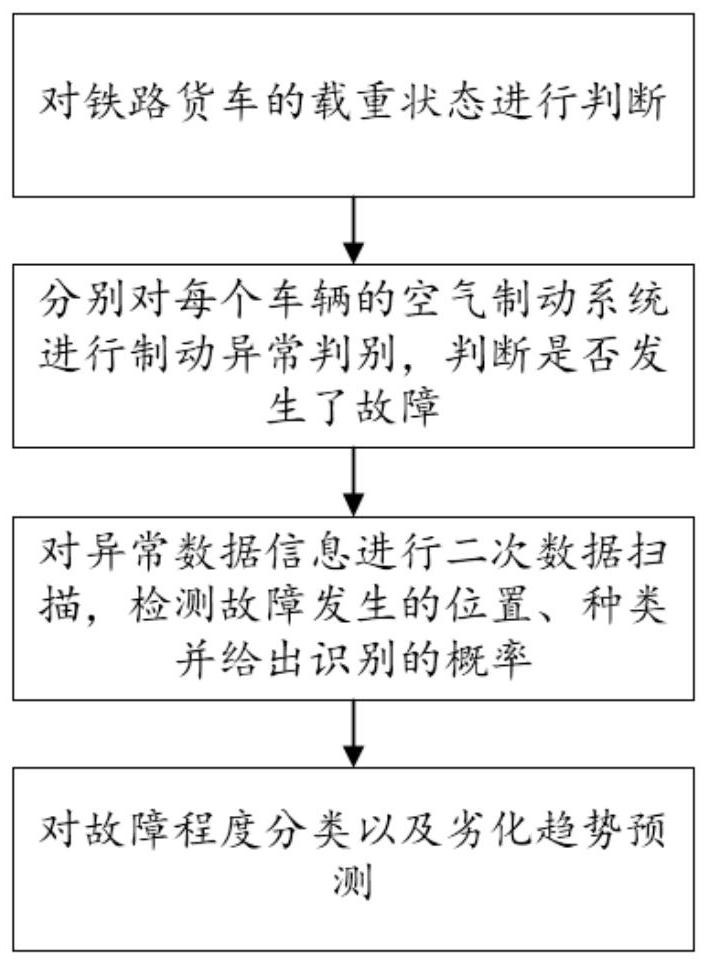

[0041] Such as figure 1 As shown, the present embodiment provides an intelligent fault detection method for an air brake device of a railway freight car, which includes the following steps:

[0042] 1. Obtain the air pressure measurement data given to the sensor under normal and different damage conditions of each component to form a training data set;

[0043] 2. Divide the cumulative pressure measurement data collected by the sensor into different braking state (braking, pressure holding and relief) data;

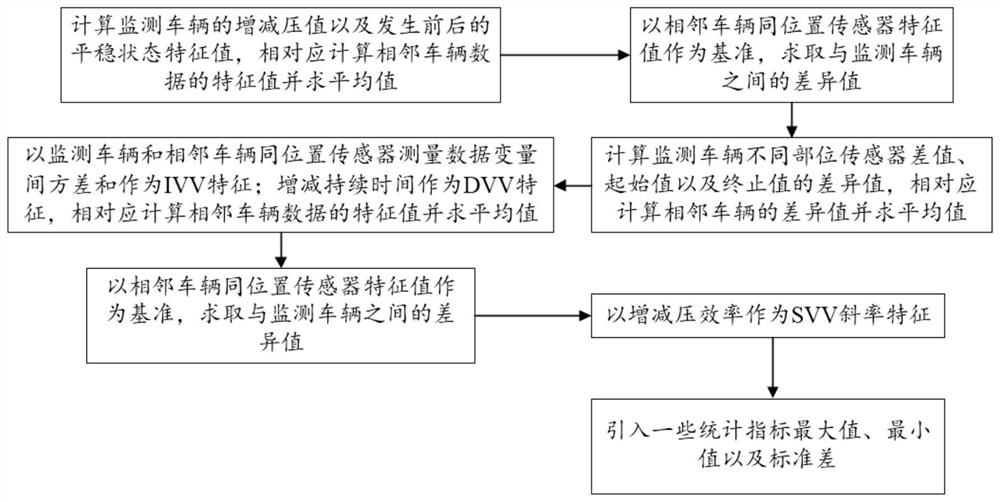

[0044] 3. Judging the braking state according to the cumulative difference function, and extracting data features. The data features include peak value, slope, duration of increase and decrease, increase and decrease amount, pressure difference between brake cylinder, auxiliary air cylinder and main pipe, and relative Variance characteristics of adjacent vehicles;

[0045] 4. Build a random forest and input the extracted data features for model parameter training. The t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com