a kind of p 2 o 5 Structural materials and their preparation methods and applications

A P2O5, structural material technology, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., to achieve the effects of good catalytic activity, good selectivity and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

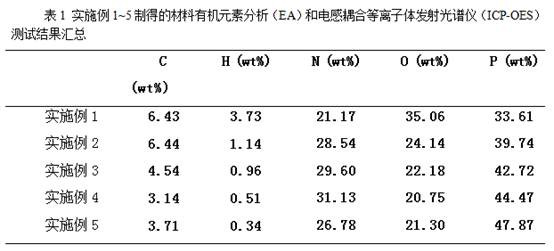

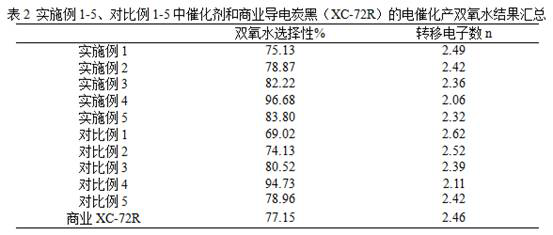

[0035] Embodiment 1: A kind of P-like for electrocatalytic production of hydrogen peroxide 2 o 5 Material (P 2 (N X o 5-X )-500) Preparation method:

[0036] Accurately weigh 1.0 g of guanidine phosphate and 1.0 g of polyvinylpyrrolidone raw materials, grind them thoroughly and place them in two crucibles. Two crucibles with precursors were placed in the tube furnace, and the crucible containing the polyvinylpyrrolidone precursor was placed upstream of the crucible containing the guanidine phosphate precursor. In access N 2 Atmosphere with 2 o C / min heating rate from room temperature to 500 o After C, calcine at constant temperature for 3 hours, then cool naturally to room temperature, take out the product in the guanidine phosphate crucible, and grind to obtain P-like 2 o 5 material of construction, denoted as P 2 (N X o 5-X )-500. the P 2 (N X o 5-X SEM images of )-500 material at 5μm and 2μm Figure 1a shown.

Embodiment 2

[0037] Embodiment 2: A kind of P-like for electrocatalytic production of hydrogen peroxide 2 o 5 Material (P 2 (N X o 5-X )-600) Preparation method:

[0038] Accurately weigh 1.0 g of guanidine phosphate and 1.0 g of polyvinylpyrrolidone raw materials, grind them thoroughly and place them in two crucibles. Two crucibles with precursors were placed in the tube furnace, and the crucible containing the polyvinylpyrrolidone precursor was placed upstream of the crucible containing the guanidine phosphate precursor. In access N 2 Atmosphere with 2 o C / min heating rate from room temperature to 600 o After C, calcine at constant temperature for 3 hours, then cool naturally to room temperature, take out the product in the guanidine phosphate crucible, and grind to obtain P-like 2 o 5 material of construction, denoted as P 2 (N X o 5-X )-600. the P 2 (N X o 5-X SEM images of )-600 material at 5μm and 2μm Figure 1b shown.

Embodiment 3

[0039] Embodiment 3: A kind of P-like for electrocatalytic production of hydrogen peroxide 2 o 5 Material (P 2 (N X o 5-X )-700) Preparation method:

[0040] Accurately weigh 1.0 g of guanidine phosphate and 1.0 g of polyvinylpyrrolidone raw materials, grind them thoroughly and place them in two crucibles. Two crucibles with precursors were placed in the tube furnace, and the crucible containing the polyvinylpyrrolidone precursor was placed upstream of the crucible containing the guanidine phosphate precursor. In access N 2 Atmosphere with 2 o C / min heating rate from room temperature to 700 o After C, calcine at constant temperature for 3 hours, then cool naturally to room temperature, take out the product in the guanidine phosphate crucible, and grind to obtain P-like 2 o 5 material of construction, denoted as P 2 (N X o 5-X )-700. the P 2 (N X o 5-X SEM images of )-700 material at 5μm and 2μm Figure 1c shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com