a ruo 2 Foamed nickel composite electrode and its preparation method and application

A composite electrode, nickel foam technology, applied in electrodes, electrolysis components, electrolysis process, etc., can solve the problems of complex treatment process and difficult removal, and achieve the effect of good cycle stability, less precious metal consumption and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

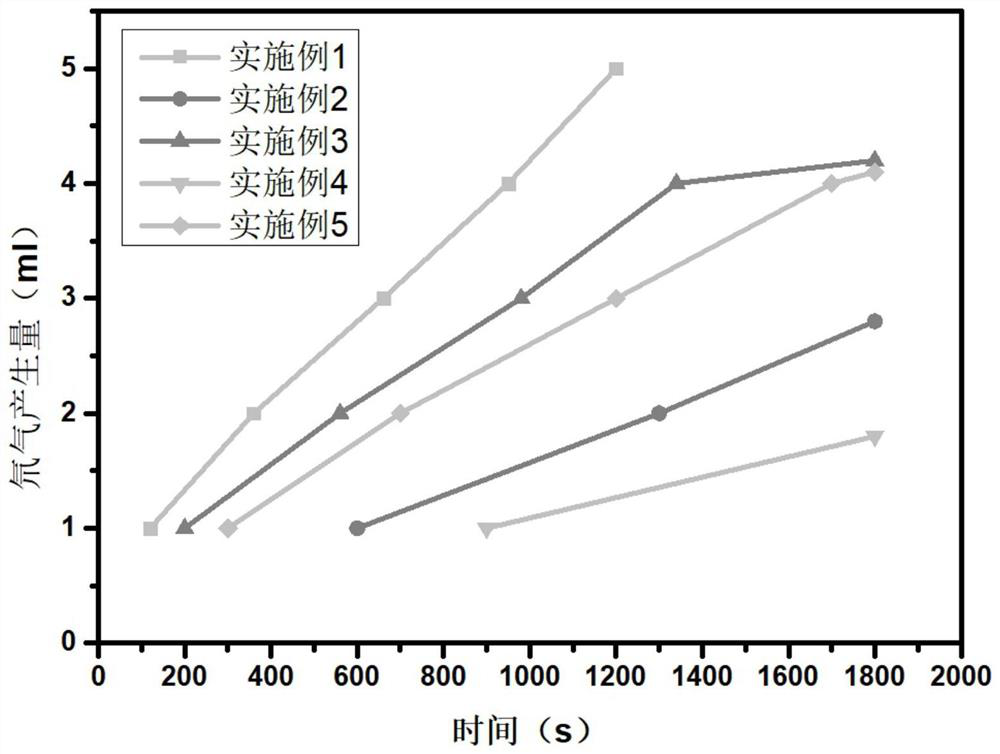

Embodiment 1

[0028] A RuO 2 The preparation of foamed nickel composite electrode (ruthenium oxide content 0.19mg) includes the following steps:

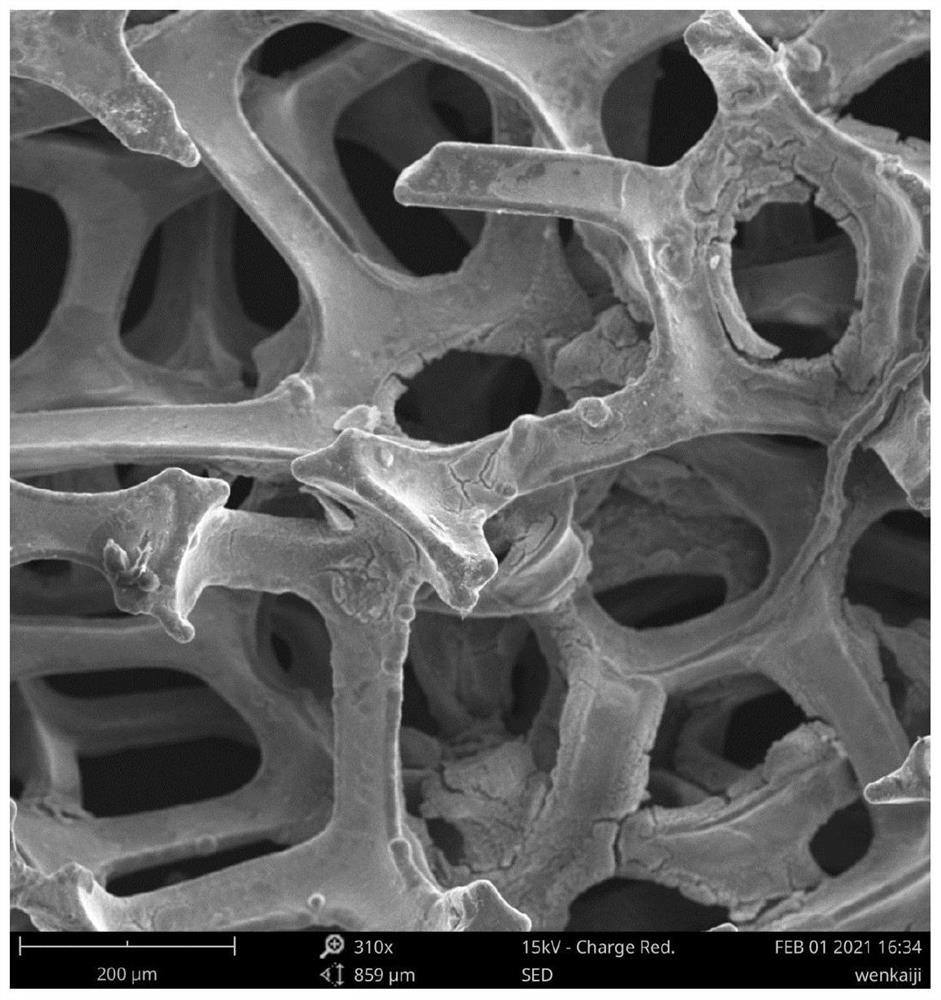

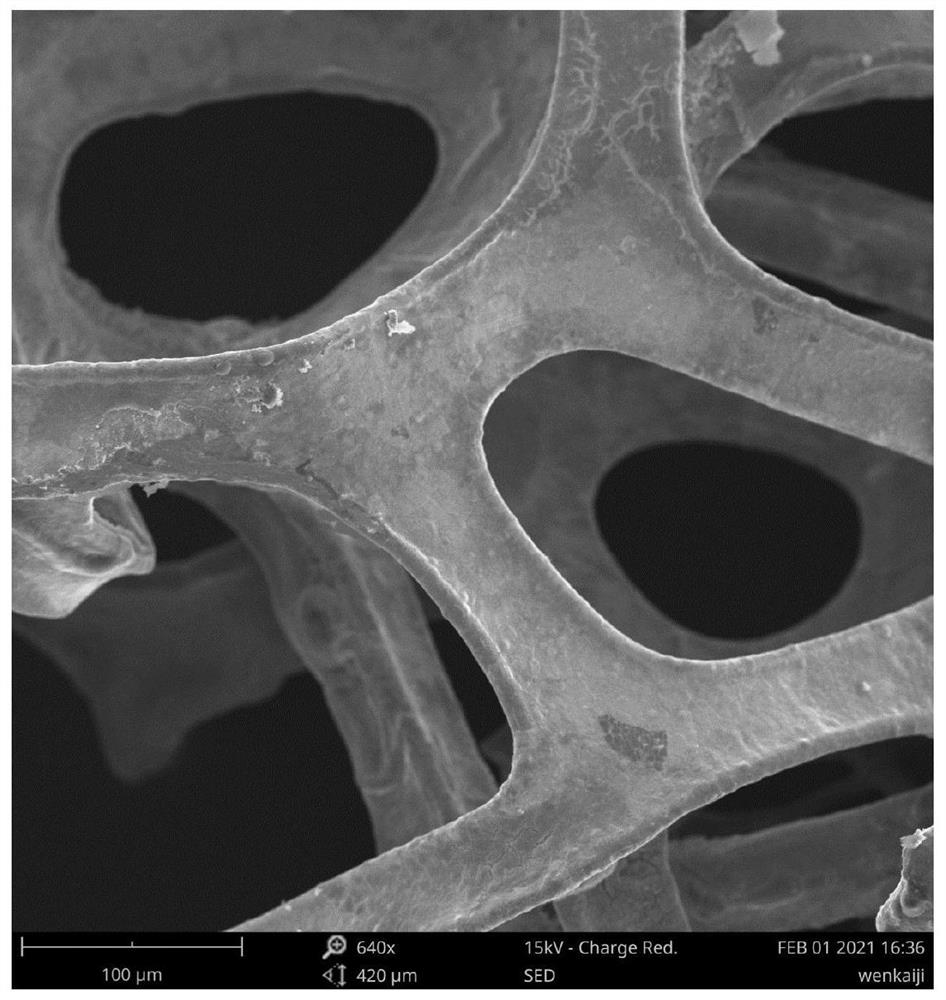

[0029] 1) Accurately weigh 30 mg of ruthenium chloride and add it to 1 ml of n-butanol, then ultrasonically dissolve it for 10 minutes to obtain a ruthenium chloride-n-butanol solution for later use; after soaking the foamed nickel in dilute hydrochloric acid with a concentration of 0.5% for 10 min, the foam The nickel is taken out and the residual hydrochloric acid on its surface is rinsed with water and dried to obtain a clean foamed nickel for later use;

[0030] 2) Use a pipette to take 10 μL of the ruthenium chloride-n-butanol solution obtained in step 1) and apply it to a clean 1*1 cm2 nickel foam, and then calcine it in a muffle furnace at high temperature in an air environment. The process is as follows: in an air environment, the temperature is uniformly heated from room temperature to 450 °C at a rate of 5 °C / min, the constant temperat...

Embodiment 2

[0032] A RuO 2 The preparation of foamed nickel composite electrode (ruthenium oxide content 0.38mg) includes the following steps:

[0033] 1) Accurately weigh 30 mg of ruthenium chloride and add it to 1 ml of n-butanol, then ultrasonically dissolve it for 10 minutes to obtain a ruthenium chloride-n-butanol solution for later use; after soaking the foamed nickel in dilute hydrochloric acid with a concentration of 0.5% for 10 min, the foam The nickel is taken out and the residual hydrochloric acid on its surface is rinsed with water and dried to obtain a clean foamed nickel for later use;

[0034] 2) Use a pipette to take 20 μL of the ruthenium chloride-n-butanol solution obtained in step 1) and apply it to the cleaned 1*1 cm2 nickel foam, and then calcine it in a muffle furnace at high temperature in an air environment. The process is as follows: in an air environment, the temperature is uniformly heated from room temperature to 450 °C at a rate of 5 °C / min, the constant temp...

Embodiment 3

[0037] A RuO 2 The preparation of foamed nickel composite electrode (ruthenium oxide content 0.57mg) includes the following steps:

[0038]1) Accurately weigh 30 mg of ruthenium chloride and add it to 1 ml of n-butanol, and then ultrasonically dissolve it for 10 minutes to obtain a ruthenium chloride-n-butanol solution for later use; after soaking the foamed nickel in dilute hydrochloric acid with a concentration of 0.5% for 10 minutes, the foam The nickel is taken out, and the residual hydrochloric acid on its surface is rinsed with water and dried to obtain a clean foamed nickel for later use;

[0039] 2) Use a pipette to take 30 μL of the ruthenium chloride-n-butanol solution obtained in step 1) and apply it to a clean 1*1 cm2 nickel foam, and then calcine it in a muffle furnace at high temperature in an air environment. The process is as follows: in the air environment, the temperature is uniformly heated from room temperature to 450 °C at a rate of 5 °C / min, the constant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com