Ru-based catalyst and preparation method and application thereof

A catalyst, the technology of cyanoguanidine, which is applied in the field of Ru-based catalyst and its preparation, can solve the problems of complicated treatment process and difficult removal, and achieve the effects of small particles, good mechanical strength and good cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

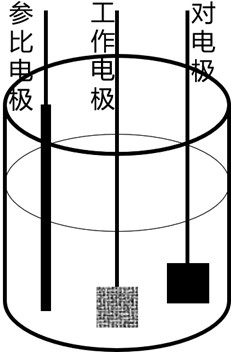

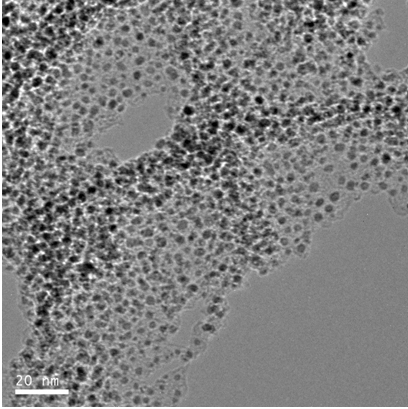

[0027] Embodiment 1: The preparation method of a kind of Ru-based catalyst (loading capacity 1%) is as follows:

[0028] Accurately weigh 1.0 g of the carrier precursor cyanoguanidine in a mortar, then weigh 30 mg of trinitronitrosyl ruthenium (II) into it, then add 1 mL of absolute ethanol to the mortar, and perform a full grinding operation until Grind and dry (volatilize with absolute ethanol). The ground and dried samples were placed in a vacuum oven for 60 o C dried for 12h, and finally the completely dried powder was placed in a tube furnace under N 2 Atmosphere, 900 o C high temperature calcination 1h (heating rate 5 o C / min), after it is naturally cooled, it is taken out and ground evenly to obtain the Ru-based catalyst with the stated load.

Embodiment 2

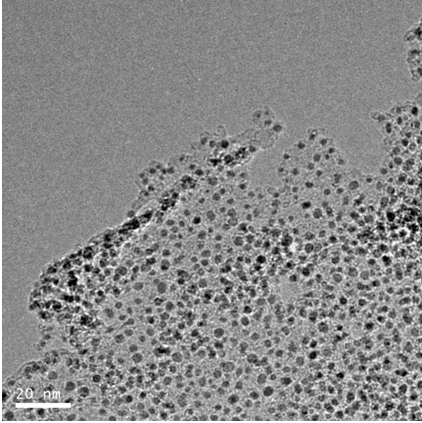

[0029] Embodiment 2: the preparation method of a kind of Ru-based catalyst (loading capacity 2%) is as follows:

[0030] Accurately weigh 1.0 g of the carrier precursor cyanoguanidine in a mortar, then weigh 60 mg of trinitronitrosyl ruthenium (II) and add it, then add 1 mL of absolute ethanol to the mortar, and perform a full grinding operation until Grind and dry (volatilize with absolute ethanol). The ground and dried samples were placed in a vacuum oven for 60 o C dried for 12h, and finally the completely dried powder was placed in a tube furnace under N 2 Atmosphere, 900 o C high temperature calcination 1h (heating rate 5 o C / min), after it is naturally cooled, it is taken out and ground evenly to obtain the Ru-based catalyst with the stated load.

Embodiment 3

[0031] Embodiment 3: the preparation method of a kind of Ru-based catalyst (loading capacity 4%) of deuterium gas produced by electrolysis of heavy water is as follows:

[0032] Accurately weigh 1.0 g of the carrier precursor cyanoguanidine in a mortar, then weigh 120 mg of trinitronitrosyl ruthenium (II) and add it, then add 1 mL of absolute ethanol to the mortar, and perform a full grinding operation until Grind and dry (volatilize with absolute ethanol). The ground and dried samples were placed in a vacuum oven for 60 o C dried for 12h, and finally the completely dried powder was placed in a tube furnace under N 2 Atmosphere, 900 o C high temperature calcination 1h (heating rate 5 o C / min), after it is naturally cooled, it is taken out and ground evenly to obtain the Ru-based catalyst with the stated load.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com