Co-based catalyst and application thereof

A catalyst and sulfide technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of complicated treatment process and difficult removal, and achieve the effect of good cycle stability, good mechanical strength and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

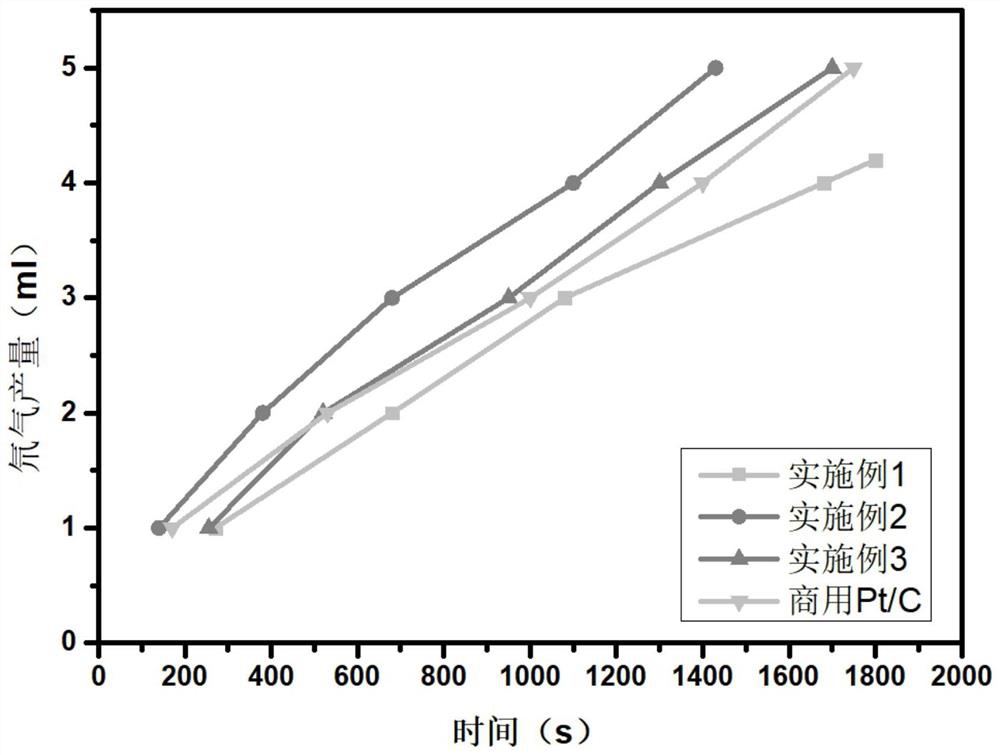

[0026] Example 1: The preparation method of a CO based catalyst (cobalt nitrate and sulfur feed ratio of 0.19: 1) is as follows:

[0027] Accurately weigh 0.095 nitrate cobalt in a mortar, adding 0.5 g of sulfur powder, then add 1 ml of anhydrous ethanol in a mortar, sufficiently polishing, until the grinding dry (absolute ethanol is volatilized during grinding) . The sample after grinding drying was placed in a vacuum oven at 60 ° C for 12h, and finally the completely dried powder was placed in a tube furnace, in N 2 Under the atmosphere, the temperature increased from the temperature of 5 ° C / min at a temperature of 5 ° C / min, then held at a constant temperature at 450 ° C, and finally cooled to room temperature, and the product in the mortar was uniform, that is, the CO group catalyst was obtained.

Embodiment 2

[0028] Example 2: The preparation method of a CO based catalyst (cobalt nitrate and sulfur feed ratio of 0.38: 1) is as follows:

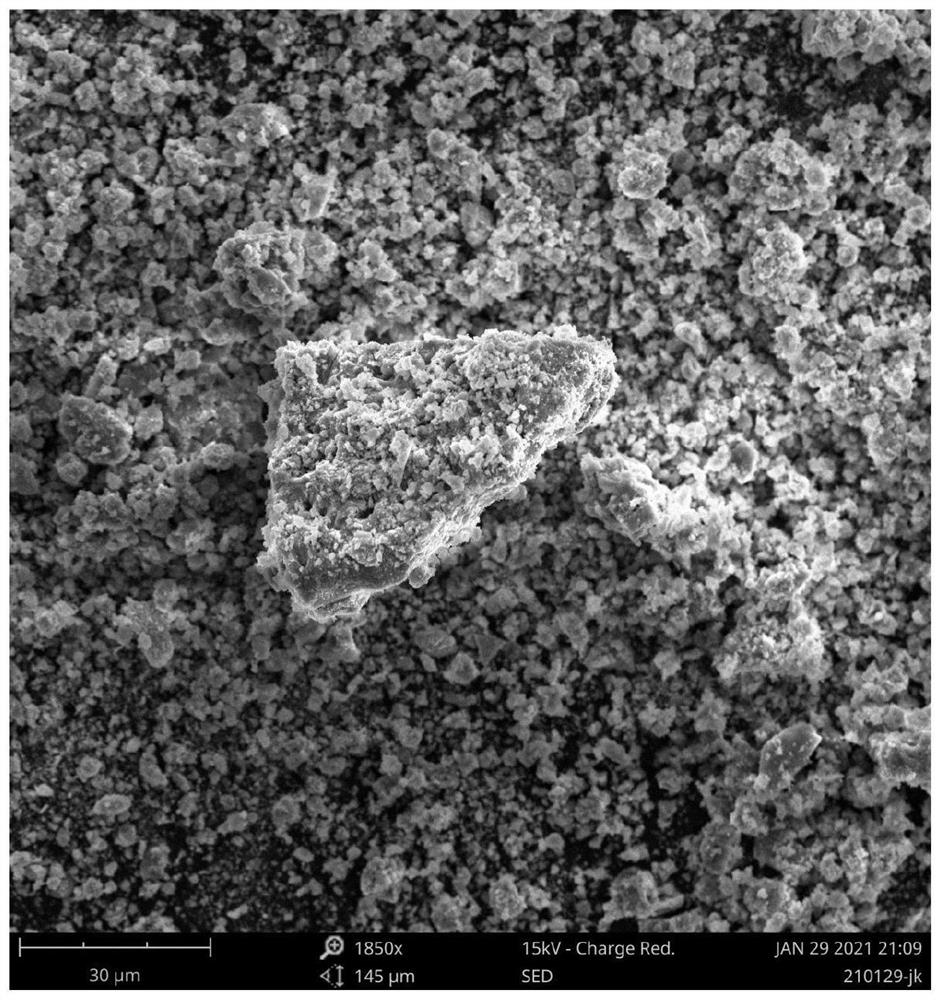

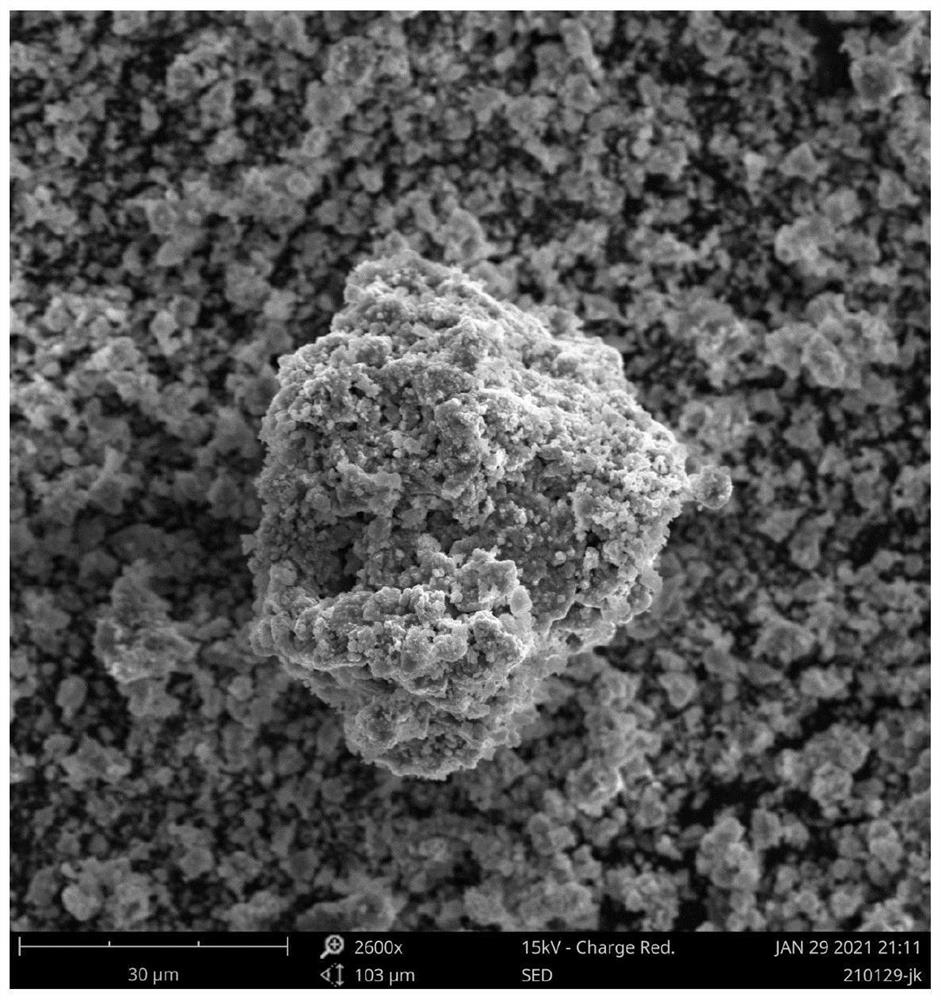

[0029] Accurately weighed 0.190 g of cobalt nitrate in a mortar, and 0.5 g of sulfur was added thereto, then 1 ml of anhydrous ethanol was added to the mortar, and sufficiently polishing is carried out until the grinding dries (absolute ethanol during the grinding process. ). The sample after grinding drying was placed in a vacuum oven at 60 ° C for 12h, and finally the completely dried powder was placed in a tube furnace, in N 2 Under the atmosphere, the temperature increased from the temperature of 5 ° C / min at a temperature of 5 ° C / min, then held at a constant temperature at 450 ° C, and finally cooled to room temperature, and the product in the mortar was uniform, that is, the CO group catalyst was obtained. Example 2 SEM map of the CO base catalyst prepared figure 1 Indicated.

Embodiment 3

[0030] Example 3: The preparation method of a CO based catalyst (cobalt nitrate and sulfur feed ratio of 0.57: 1) is as follows:

[0031] Accurately weigh 0.285 g of cobalt nitrate in a mortar, then weigh 0.5 g of sulfur powder, then add 1 ml of anhydrous ethanol in a mortar, sufficiently polishing, until the grinding dry (absolute ethanol is volatilized during grinding) ). The sample after grinding drying was placed in a vacuum oven at 60 ° C for 12h, and finally the completely dried powder was placed in a tube furnace, in N 2 Under the atmosphere, the temperature increased from the temperature of 5 ° C / min at a temperature of 5 ° C / min, then held at a constant temperature at 450 ° C, and finally cooled to room temperature, and the product in the mortar was uniform, that is, the CO group catalyst was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com