Preparation method of flower-like silicon dioxide abrasive particles

A silicon dioxide and flower-shaped technology, applied in the direction of silicon dioxide, silicon oxide, chemical instruments and methods, etc., can solve the problem of low polishing rate of spherical silicon oxide abrasive grains, achieve more effective contact sites, and reduce surface roughness Degree, effect suitable for promotional use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

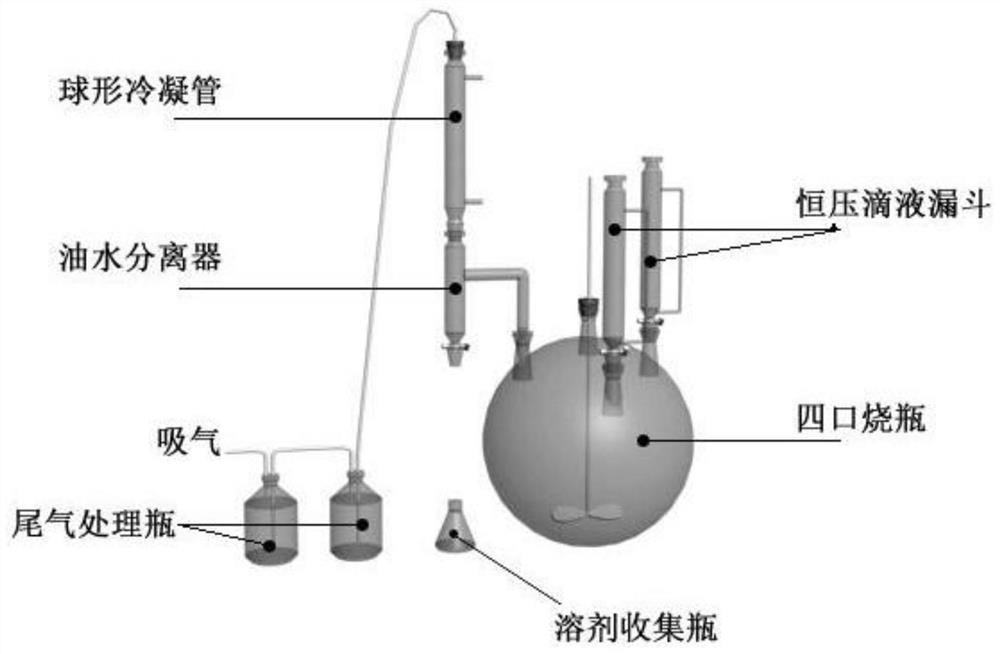

[0020] A kind of preparation method of flower-shaped silica abrasive grain provided by the invention comprises the following steps:

[0021] S01: Add polyvinylpyrrolidone (PVP) into n-amyl alcohol, stir until the polyvinylpyrrolidone is completely dissolved, add absolute ethanol and 0.36M sodium citrate solution, stir until the solution becomes cloudy, then add 25wt.% ammonia water, stir And the mixed solution was heated, then slowly added tetraethyl orthosilicate (TEOS) dropwise, continued to stir, continued the reaction at a constant temperature of 70°C for 2h, sealed and cooled for 24h, and obtained flower-like silica seeds; among them, PVP, n-pentanol , absolute ethanol, 0.36M sodium citrate solution, 25wt.% ammonia water, and the mass ratio of TEOS are: 6-10: 122-244: 20: 10: 4-9: 5-10.

[0022] S02: passing 8wt.% of the water glass solution through a cation exchange resin pretreated with HCl to obtain a silicic acid solution with an activity of 2 to 3wt.%.

[0023] S03:...

Embodiment 1

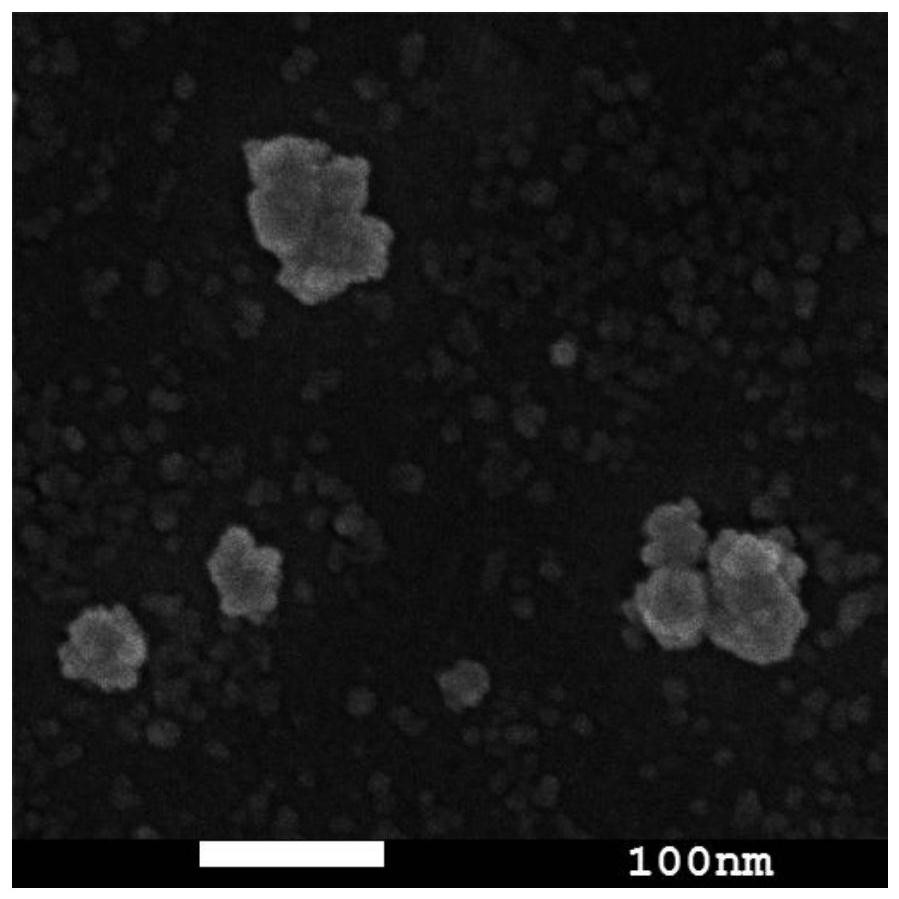

[0027] This example provides a method for preparing flower-shaped silica nano-abrasive particles. The flower-shaped silica nano-abrasive particles are prepared by a dual-system microemulsion template method. The method steps are as follows:

[0028] (1) Add 6g of PVP into a three-necked flask with 300ml of n-pentanol, stir until the PVP is completely dissolved, add 25ml of absolute ethanol and 10ml of 0.36M sodium citrate solution, stir until the solution becomes cloudy, then add 5ml 25wt.% ammonia water, stirred and heated the mixed solution to 70°C, then slowly added 5ml of tetraethyl orthosilicate (TEOS) dropwise, after the dripping, continued to stir, kept the temperature at 70°C for 2h, then poured it into a beaker, Sealed and cooled overnight to obtain flower-shaped silica seeds.

[0029] (2) A certain amount of 8wt.% water glass (Na 2 SiO 3 ) solution was passed through the cation exchange resin pretreated with HCl to obtain a freshly prepared 2 wt.% active silicic ac...

Embodiment 2

[0034] This example provides a method for preparing flower-shaped silica nano-abrasive particles. The flower-shaped silica nano-abrasive particles are prepared by a dual-system microemulsion template method. The method steps are as follows:

[0035] (1) Add 7g of PVP into a three-necked flask containing 300ml of n-pentanol, stir until the PVP is completely dissolved, add 25ml of absolute ethanol and 10ml of 0.36M sodium citrate solution, stir until the solution becomes cloudy, then add 6.75 ml25wt.% ammonia water, stirred and heated the mixed solution to 70°C, then slowly added 6ml of tetraethyl orthosilicate (TEOS) dropwise, after the dripping, continued to stir, 70°C constant temperature to continue the reaction for 2h, then poured into a beaker, Sealed and cooled overnight to obtain flower-shaped silica seeds.

[0036] (2) Pass the 8wt.% water glass solution through the cation exchange resin pretreated with HCl to obtain a 3wt.% active silicic acid solution;

[0037] (3) A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com