Continuous-conveyance type coating system

A technology for conveying paint and nitrogen, which is applied in the field of paint, can solve problems such as inability to guarantee conveying and spraying, and affect the effect of spraying, and achieve a simple and practical effect suitable for popularization and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is further described in conjunction with the following examples.

[0015] Application Scenario 1:

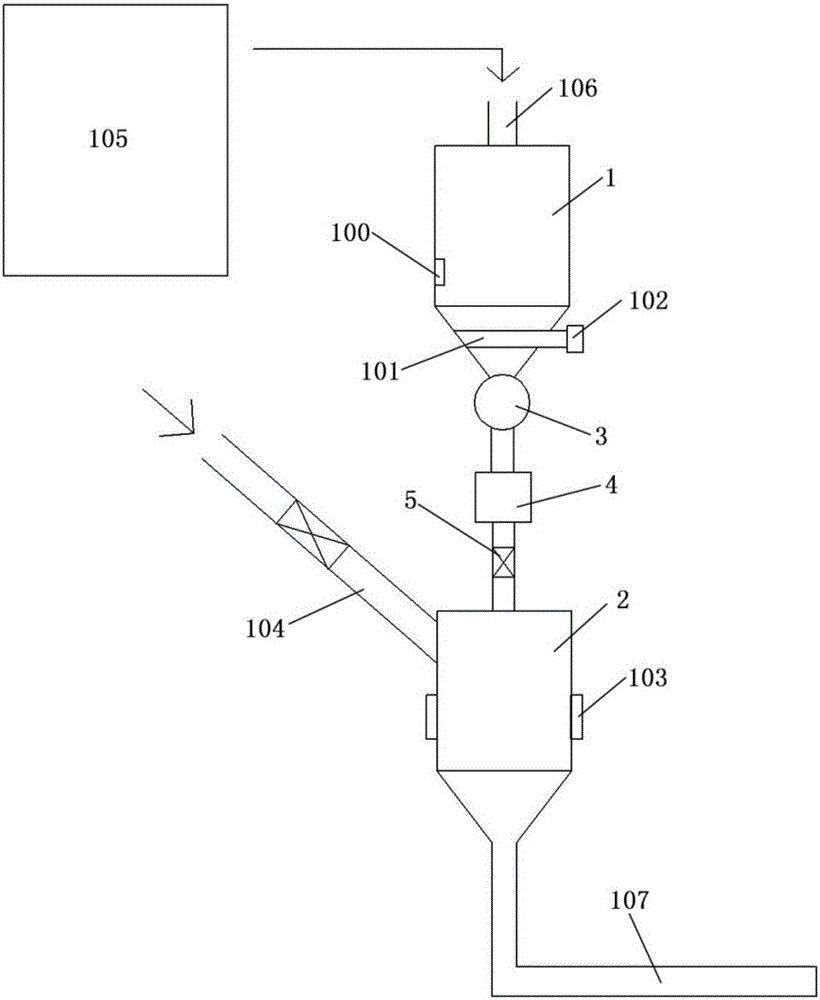

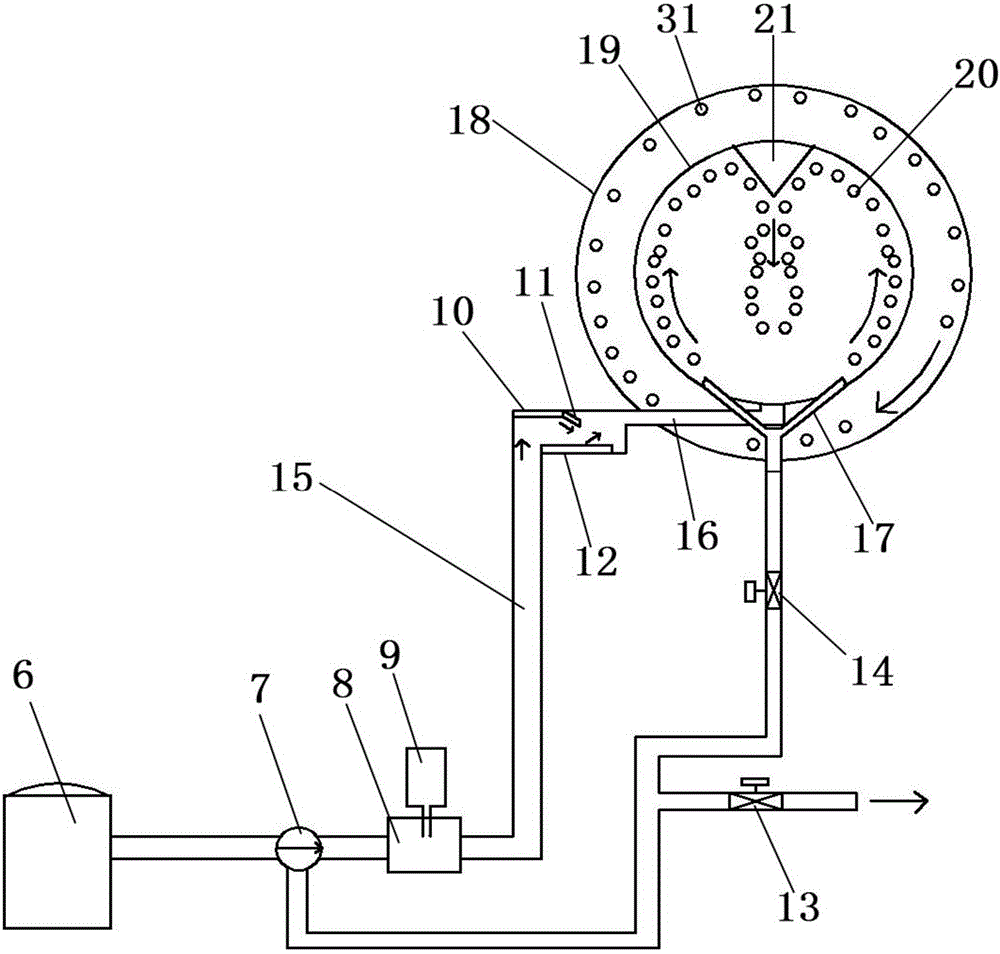

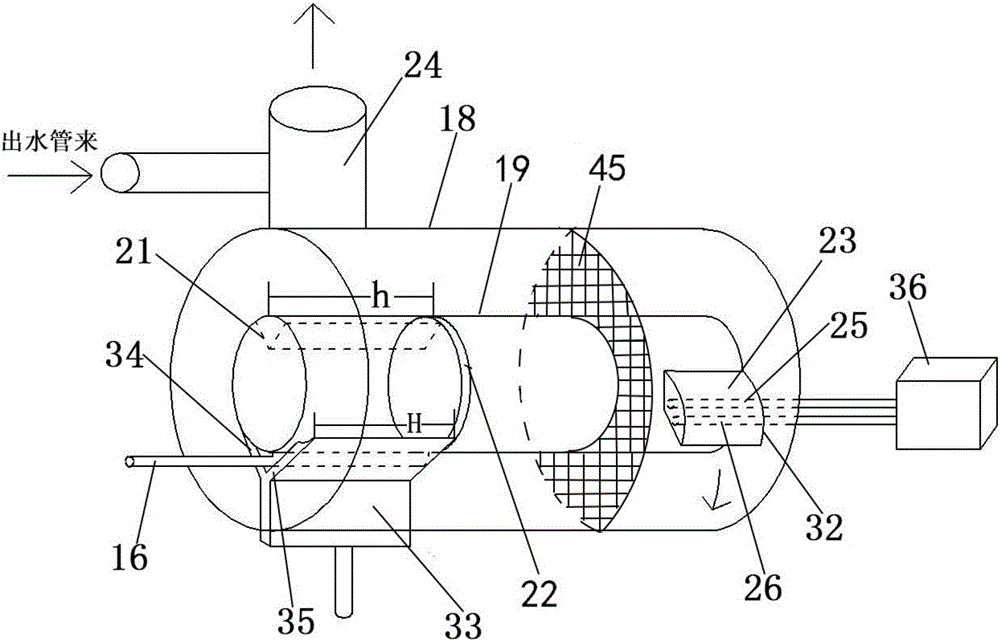

[0016] Such as figure 1 The continuous conveying paint system shown includes a storage hopper 1, a vibrating bucket 2, a screw conveyor 3, a feeder 4 and an isolation manual valve 5. A material level detector 100 is arranged on the inner wall of the storage hopper 1, and the screw The conveyor 3 is set at the bottom of the storage hopper 1, the feeder 4 and the isolation manual valve 5 are set on the pipeline between the screw conveyor 3 and the vibrating bucket 2, and the bottom of the storage hopper 1 is located at the screw conveyor 3 The top of the vibrating bucket 2 is also provided with a rotating rod 101 for preventing clogging, and the rotating rod 101 is driven by a motor 102 to rotate; the vibrating bucket 2 is provided with a plurality of vibrating devices 103, and the upper part of the vibrating bucket 2 is connected with a nitrogen deli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com