Loading mechanism of video monitoring camera

A technology of video monitoring and loading mechanism, which is applied in the field of surveillance cameras, can solve problems such as prone to danger, staying at a high place, troublesome adjustment process, etc., and achieve the effect of reducing danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

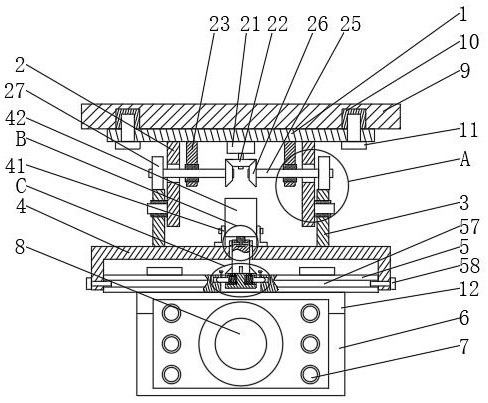

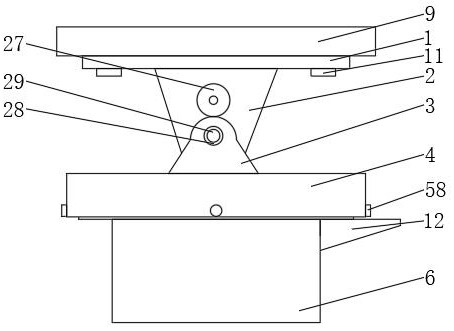

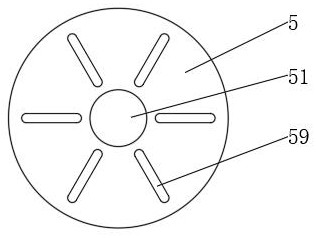

[0026] A loading mechanism for a video surveillance camera, comprising a mounting plate 1, a support plate 2, a rotating plate 3, a rotating cover 4, a turntable 5, a camera box 6, a fill light 7, a lens 8, a wall surface 9, an expansion screw barrel 10 and Fixed slot 49, the lower end of the mounting plate 1 is fixedly connected with a support plate 2, the lower end of the support plate 2 is rotatably connected with a rotating plate 3, and the lower end of the rotating plate 3 is fixedly connected with a rotating cover 4, and the rotating cover 4 is connected with a turntable 5 for rotation, the lower end of the turntable 5 is connected with a camera box 6 by bolts, the inside of the camera box 6 is provided with a supplementary light 7, and the inside of the camera box 6 is provided with a lens 8, so The upper end of the installation plate 1 is connected with a wall surface 9 by bolts, and the inside of the wall surface 9 is fixedly connected with an expansion screw cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com