Three-dimensional morphology measuring method and device

A measurement method and technology of three-dimensional topography, applied in the field of measurement, can solve the problems of poor measurement accuracy, long time, low sensitivity of three-dimensional topography, etc., and achieve the effect of accurate and fast measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

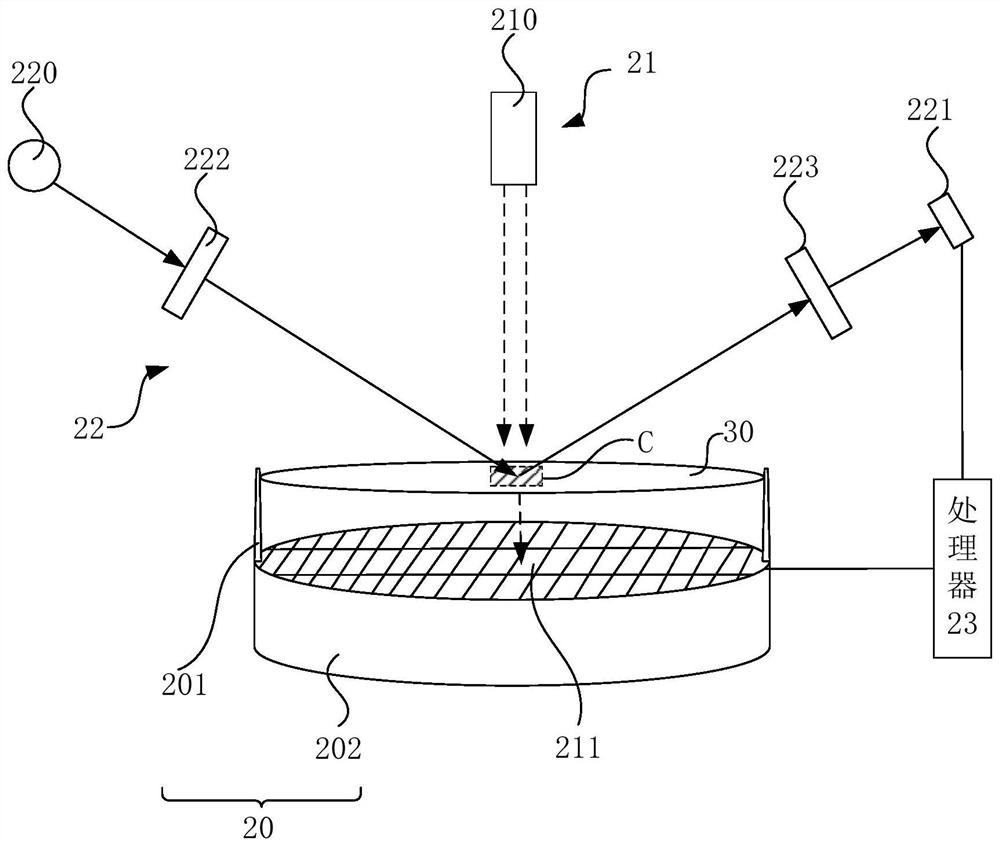

[0022] The specific implementations of the three-dimensional shape measurement method and the measurement device provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

[0023] A specific embodiment of the method for measuring the three-dimensional shape of the present invention is based on the optical critical dimension measurement method combined with the X-ray imaging method to obtain the three-dimensional shape of the sample.

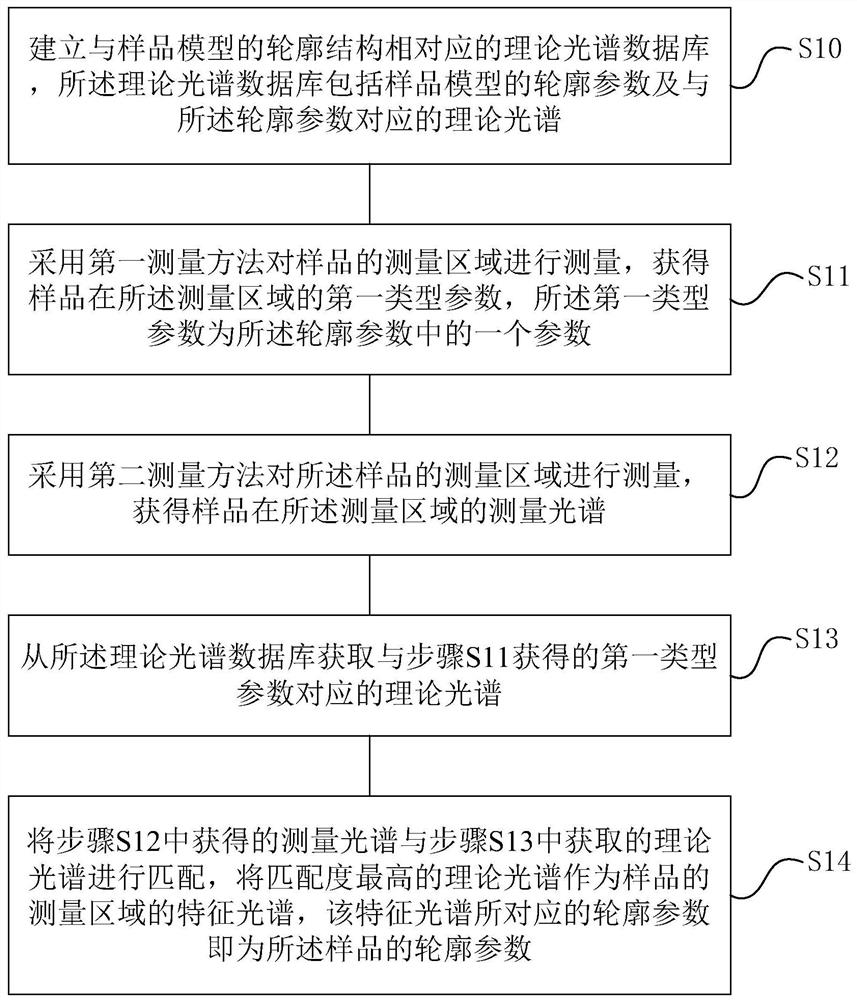

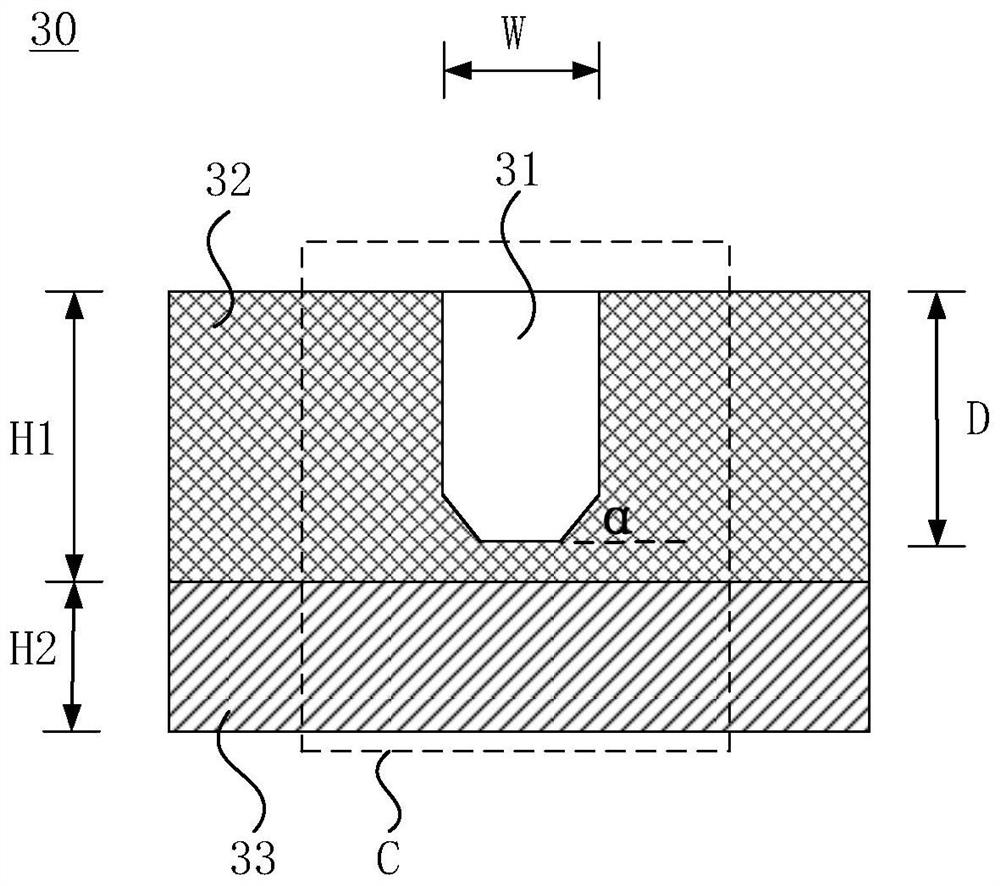

[0024] The basic working principle of optical critical dimension measurement (OCD) can be described as: (1) establish a theoretical spectral database corresponding to the profile structure of the sample model; (2) obtain the measurement spectrum of the sample through optical critical dimension measurement equipment; (3 ) Find the characteristic spectrum that best matches the measured spectrum from the theoretical spectrum database, so as to determine the profile parameters of the sample. Th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap