Autonomous Control Method of Spacecraft Orbit Control Load Power Consumption

A technology for autonomous control and spacecraft, applied in the electrical field of spacecraft, can solve the problems of large transient voltage fluctuation of power supply bus, hidden danger of electricity consumption, increase of instantaneous peak power, etc., to prevent spacecraft electricity safety problems and guarantee The effect of electricity supply and demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments. The embodiments cannot be repeated here, but the embodiments of the present invention are not limited to the following embodiments.

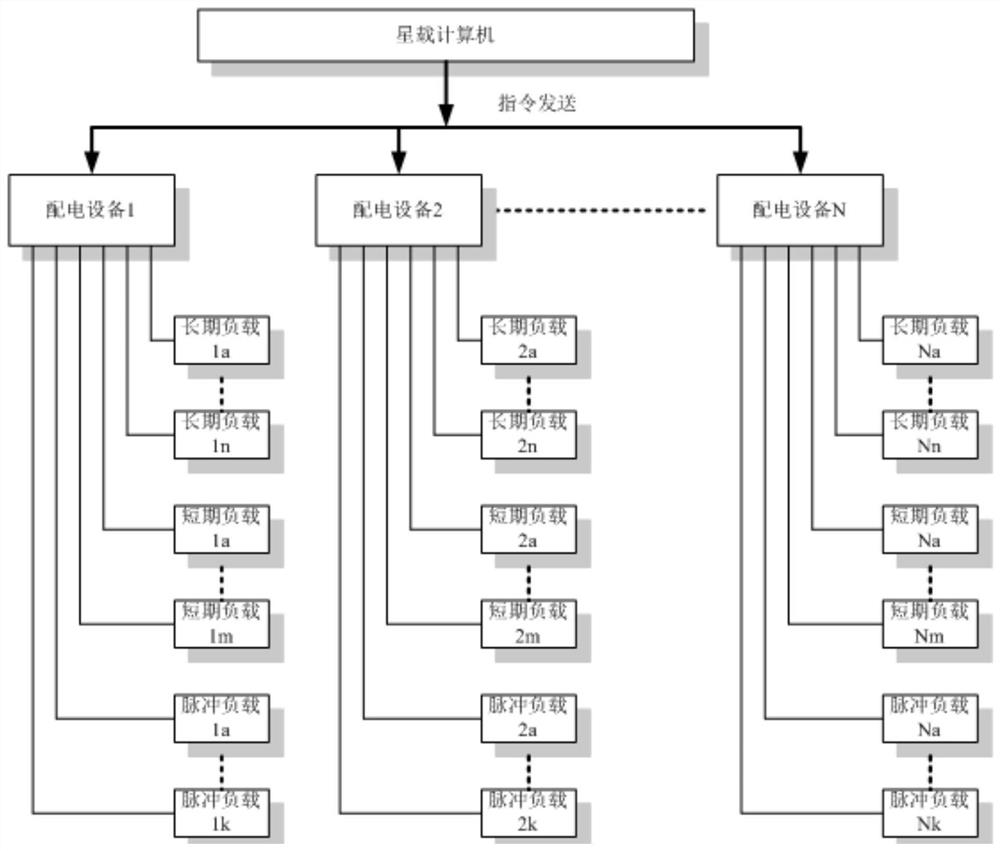

[0026] combine figure 1 As shown, the present invention proposes a method for supporting autonomous control of load power consumption during spacecraft orbit control, which is based on the typical electrical system topology architecture of the spacecraft and expands the autonomous management function of the spacecraft during orbit flight. Conducted more in-depth research on the key flight event of the spacecraft - the load power management and control of orbit control, and realized short-term load or pulse load on orbit control engines, attitude control engines, heaters, load equipment, etc. during spacecraft orbit control. The autonomous scheduling of time-sharing work and the autonomous control of the power consu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com