A konjac stringing device for restaurants

A konjac and stringing technology is applied in the field of konjac stringing devices used in restaurants, which can solve the problems of low efficiency and waste time, and achieve the effect of improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

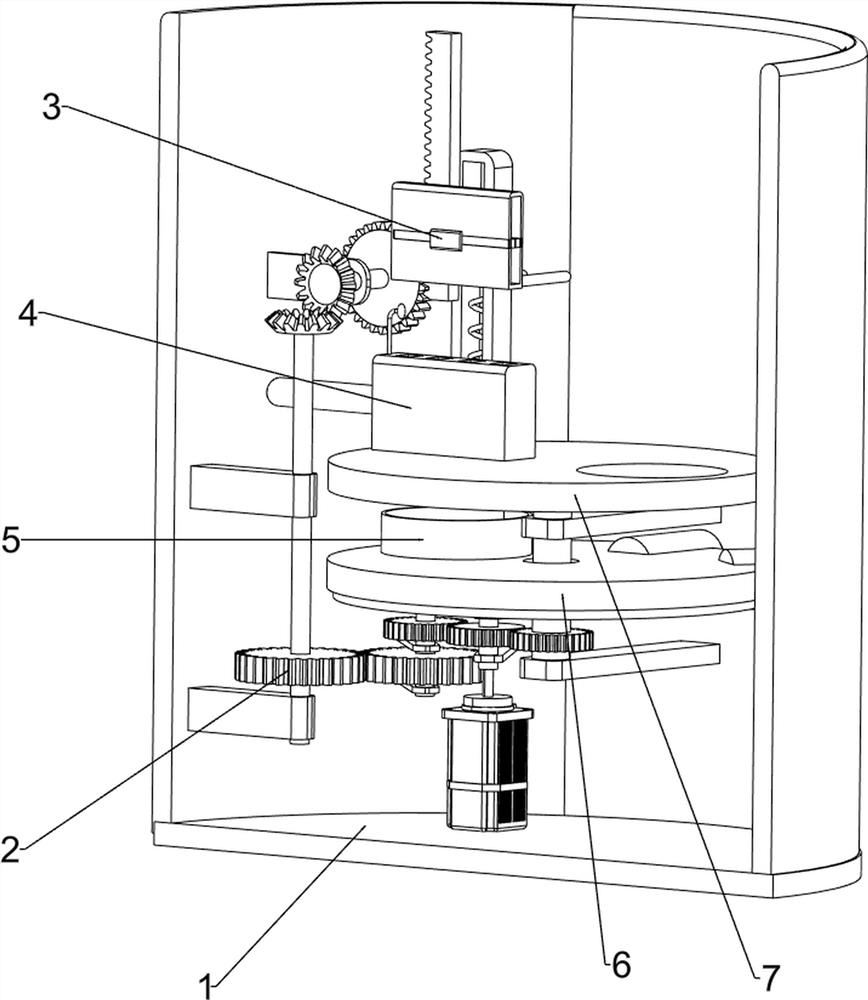

[0059] A konjac stringing device for restaurants, such as figure 1 As shown, it includes a base 1, a lifting mechanism 2, a clamping mechanism 3 and a blanking frame 4, a lifting mechanism 2 is arranged on the inner wall of the base 1, a blanking frame 4 is arranged in the middle of the inner left wall of the base 1, and the lifting mechanism 2 and the lower The material frame 4 is provided with a clamping mechanism 3 .

[0060] When it is necessary to string konjac, first insert the bamboo stick into the lifting mechanism 2, and then continue to insert it into the clamping mechanism 3 for clamping, and put the cut konjac into the unloading frame 4, press the konjac with your hand, and then Start the lifting mechanism 2, the lifting mechanism 2 moves downward, and drives the clamping mechanism 3 to move downward, thereby driving the bamboo sticks to move downward and insert them into the konjac below, so that a string can be formed, and then the clamping mechanism 3 releases t...

Embodiment 2

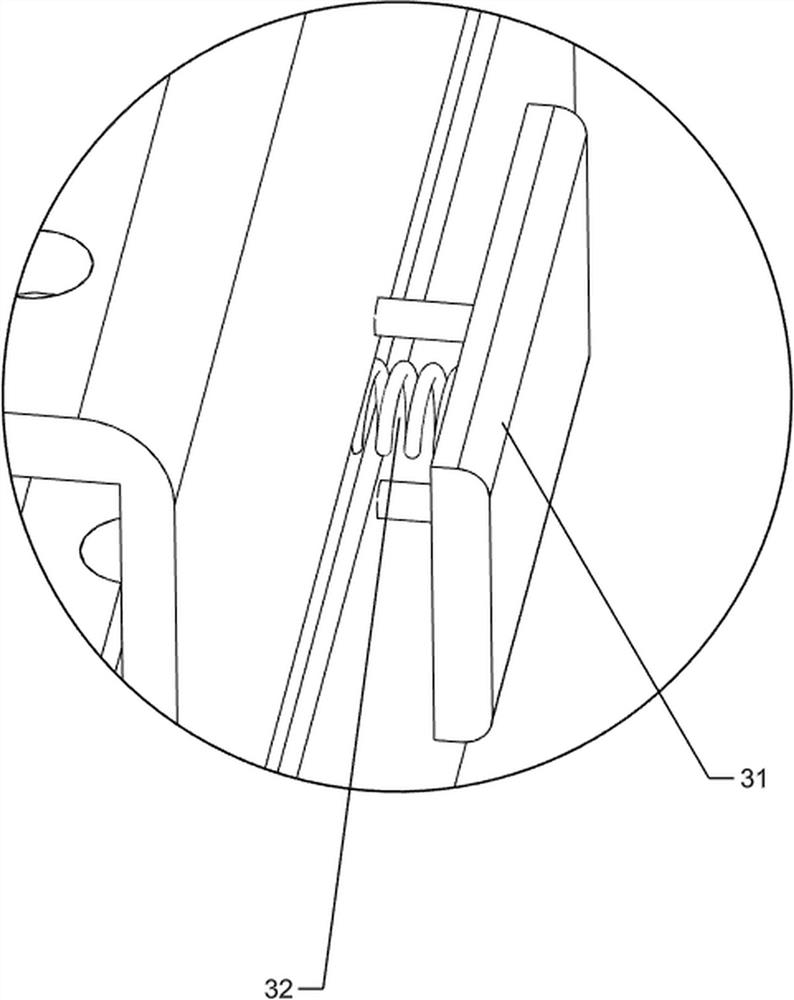

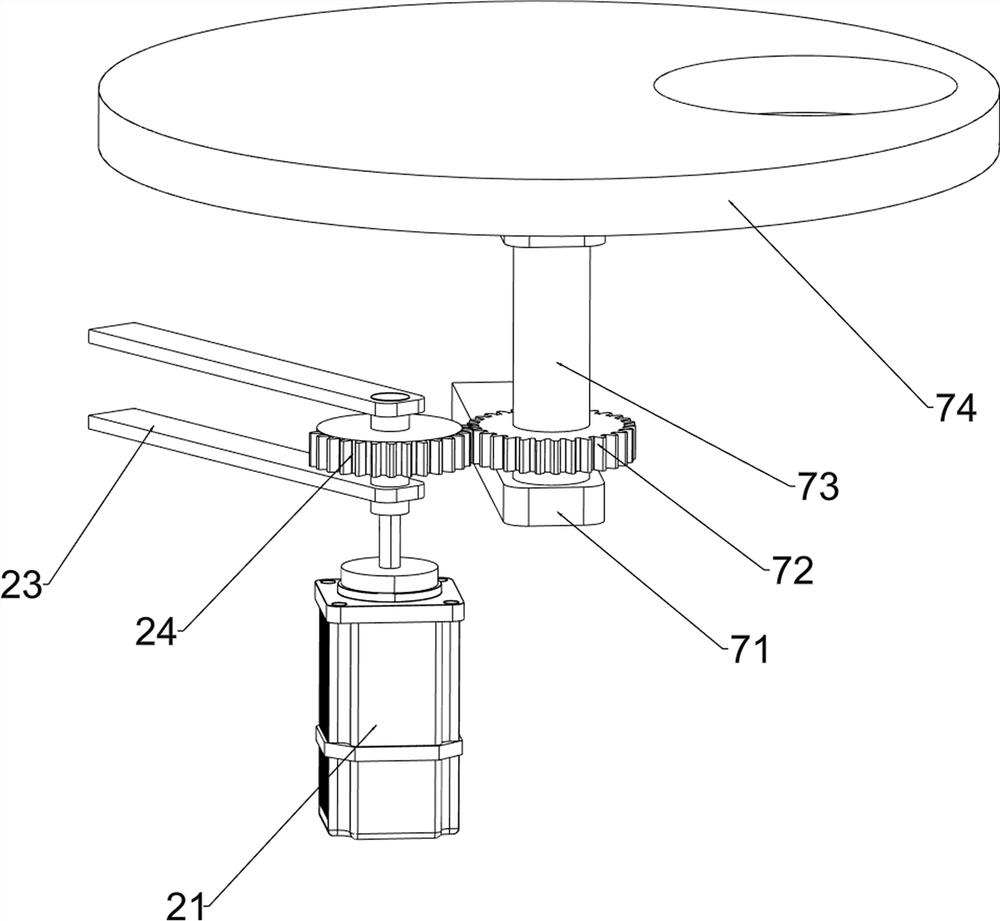

[0062] On the basis of Example 1, as figure 2 , image 3 and Figure 4As shown, the lifting mechanism 2 includes a motor 21, a first rotating shaft 22, a first supporting plate 23, a missing gear 24, a second rotating shaft 25, a second supporting plate 26, a first circular gear 27, a second circular gear 28, Three supporting plates 29 , bevel gear assembly 210 , third rotating shaft 211 , fourth supporting plate 212 , third circular gear 213 , rack 214 , slider 215 , guide rail 216 , first spring 217 , connecting rod 218 and clamp frame 219 , a motor 21 is installed on the inner and lower walls of the base 1, and a first support plate 23 is provided on the upper and lower parts of the left wall of the base 1. The right part of the first support plate 23 is rotatably provided with a first rotating shaft 22. The output shaft of the motor 21 is connected, the middle of the first rotating shaft 22 is provided with a missing gear 24, the lower part of the inner left wall of the...

Embodiment 3

[0067] On the basis of Example 2, as figure 1 and Figure 5 As shown, it also includes a collecting frame 5, a rotating disk 6 and a rotating mechanism 7, a rotating mechanism 7 is provided on the inner wall of the base 1, a rotating disk 6 is provided on the rotating mechanism 7, and the rotating disk 6 is slidably connected with the inner rear wall of the base 1. , a collection frame 5 is provided on the left side of the top of the rotating disc 6 .

[0068] In the process of collecting bunches of konjac, after the cut konjac is placed in the unloading frame 4, the rotating mechanism 7 is pressed against the konjac, and there is no need for people to resist it manually. The opened bunches of konjac fall into the collection frame 5 through the rotating mechanism 7. After the collection frame 5 is full, people turn the rotary disk 6 to drive the collection frame 5 to rotate to the outside, and take out the bunches of konjac. The missing gear 24 continues to rotate to make the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com