Screening facility used before agricultural seed sowing

A screening equipment and technology for agricultural seeds, applied in agriculture, seed and rhizome treatment, screening, etc., can solve the problems of incapability, screening, and impossibility of seed screening, and achieve the effect of preventing seed quality from declining and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

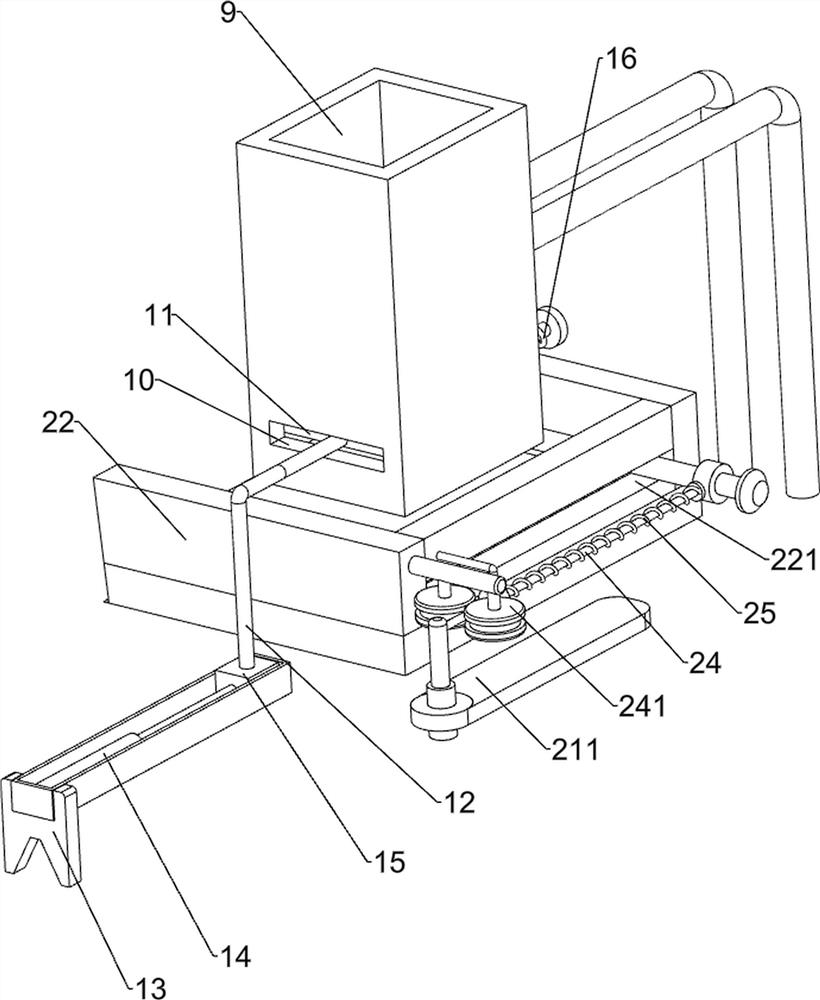

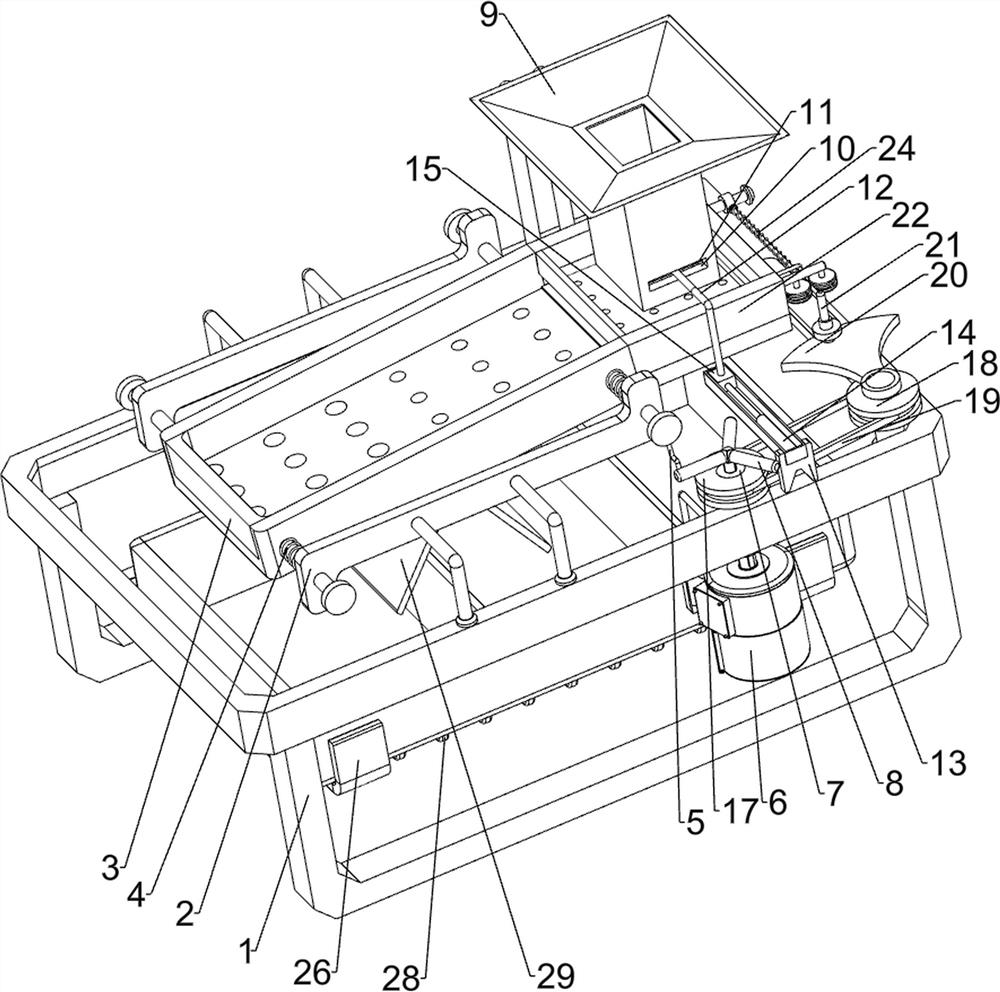

[0021] A pre-sowing screening equipment for agricultural seeds, such as Figure 1-Figure 4 As shown, it includes a frame 1, a screening assembly, a drive assembly and a blanking assembly. The frame 1 is used to install the entire device. The drive assembly that provides power to push is provided at the top, and the rear right part of the frame 1 is provided with a blanking assembly that performs blanking by sliding.

[0022] When the seeds need to be screened, first pour an appropriate amount of seeds into the feeding assembly, then put the seed collection container under the screening assembly, start the drive assembly to work, so that the seeds in the feeding assembly slide down to the screening assembly , and then drive the screening component to screen the size of the seeds. After all the seeds are screened, close the drive component and take away the seed collection container.

[0023] like figure 1 and figure 2 As shown, the screening assembly includes a fixed plate ...

Embodiment 2

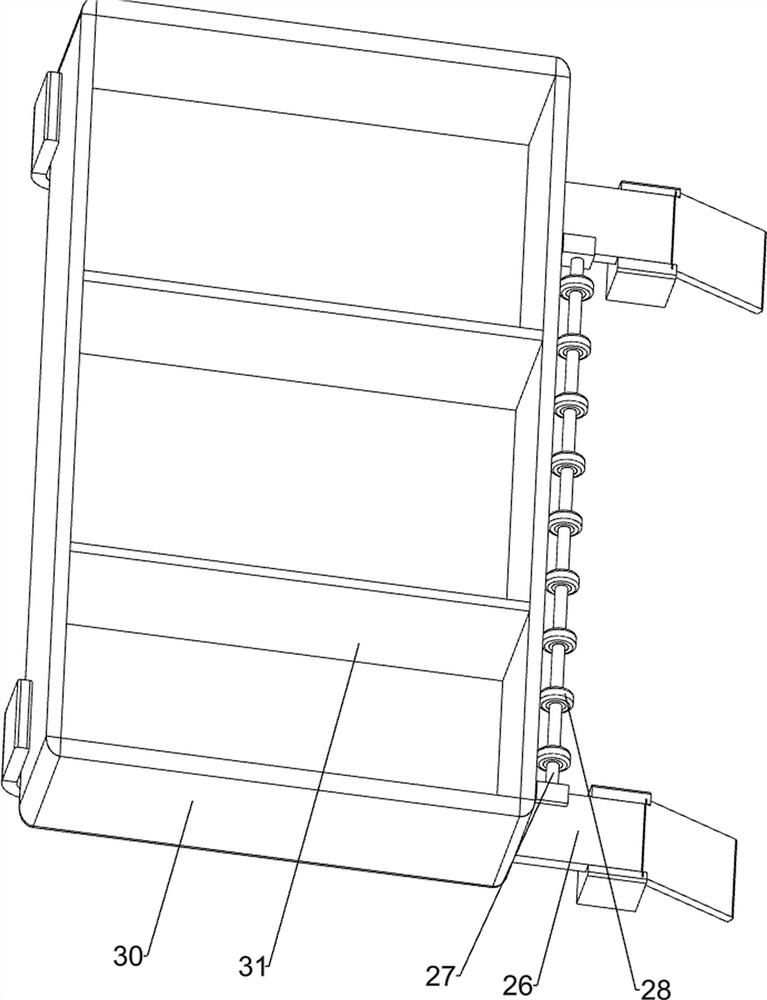

[0029] On the basis of Example 1, such as figure 1 , figure 2 and Figure 4 Shown, also include toggling bar 23, steel wire 24, pulley 241 and the 3rd spring 25, there is a word hole 221 in the lower part of dust removal frame 22 right sides, and the sliding type in the word hole 221 is provided with toggling lever 23, A steel wire 24 is connected between the toggle lever 23 and the first fixed rod 21. The right side of the dust removal frame 22 is rotatably provided with two pulleys 241. The steel wire 24 cooperates with the pulley 241. A third spring 25 is connected between them.

[0030]When the first fixed rod 21 moved forward, the steel wire 24 was pulled to move forward, and the third spring 25 was compressed to drive the toggle rod 23 to slide forward to stir the seeds. When the first fixed rod 21 moved backward, Under the effect of the third spring 25, the steel wire 24 and its upper device are moved backward and reset to stir the seeds again. In this way, the dust...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap