Placing structure for elevator

A hoist and rotating mechanism technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of time-consuming and labor-intensive, increase the labor load of staff, increase the length of fire extinguisher handling, etc., to improve transfer efficiency and reduce work volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

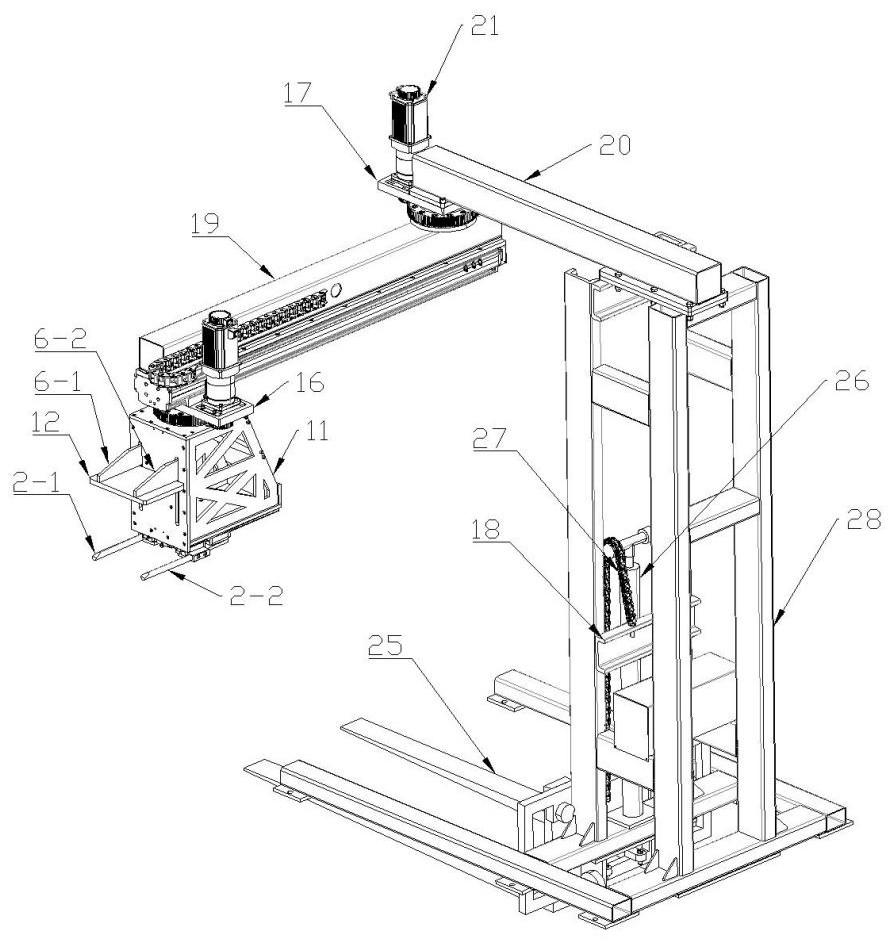

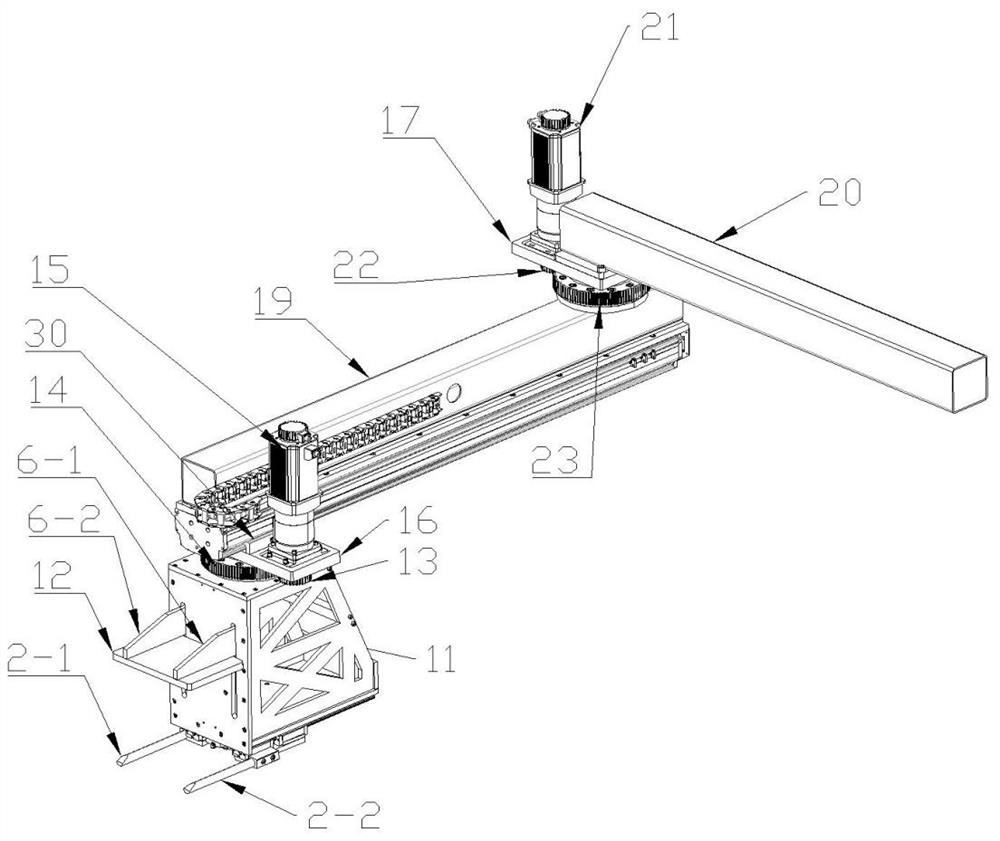

[0026] Such as figure 2 As shown, a placement structure for a hoist includes a material receiving and unloading device and a swing arm device. The swing arm device includes a swing arm rotation mechanism and a forward and backward movement mechanism. The arm member rotates with the swing arm member, and the connecting and unloading device is installed on the forward and backward moving mechanism, and the forward and backward moving mechanism drives the connecting and unloading device to move forward and backward.

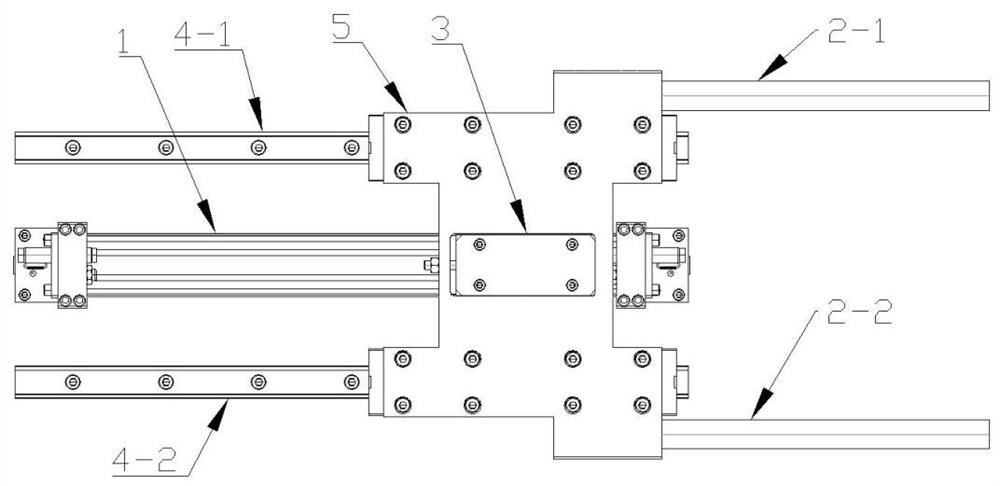

[0027] The receiving and unloading device comprises a support 11, a shoveling mechanism and a rotating mechanism, the shoveling mechanism is installed on the bottom of the support 11, and the rotating mechanism is installed on the top of the support 11, and the shoveling mechanism includes a shoveling power component and a shoveling component, and the shoveling power The shoveling power part of the component is connected to the shoveling component and pushes the sh...

Embodiment 2

[0043] A placement structure for a hoist, which differs from Embodiment 1 in that a hoisting device is added, which facilitates subsequent placement of materials.

[0044] Such as figure 1 As shown, the lifting device is installed on the support frame I 28, including a lifting power component and a material receiving part, and the lifting power component is connected with the material receiving part and drives the material receiving part to move up and down.

[0045] The lifting power component includes a chain III 27 and an oil cylinder 26, the upper part of the piston rod of the oil cylinder 26 can be provided with a sprocket, the chain III 27 bypasses the sprocket, and the two ends of the chain III 27 are respectively connected with the fixed rod 18 and the material receiving part. Engaged with the sprocket, the chain III27 and the sprocket can also be replaced by belts and pulleys; the piston rod of the oil cylinder 26 moves up and down, driving the chain III27 to move, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com