Pneumatic device of glass cutting machine

A pneumatic device and cutting machine technology, applied in the direction of glass cutting device, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of not being able to rotate the glass, not being able to move the whole device, and inconvenient glass, so as to increase stability and facilitate cutting operations Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

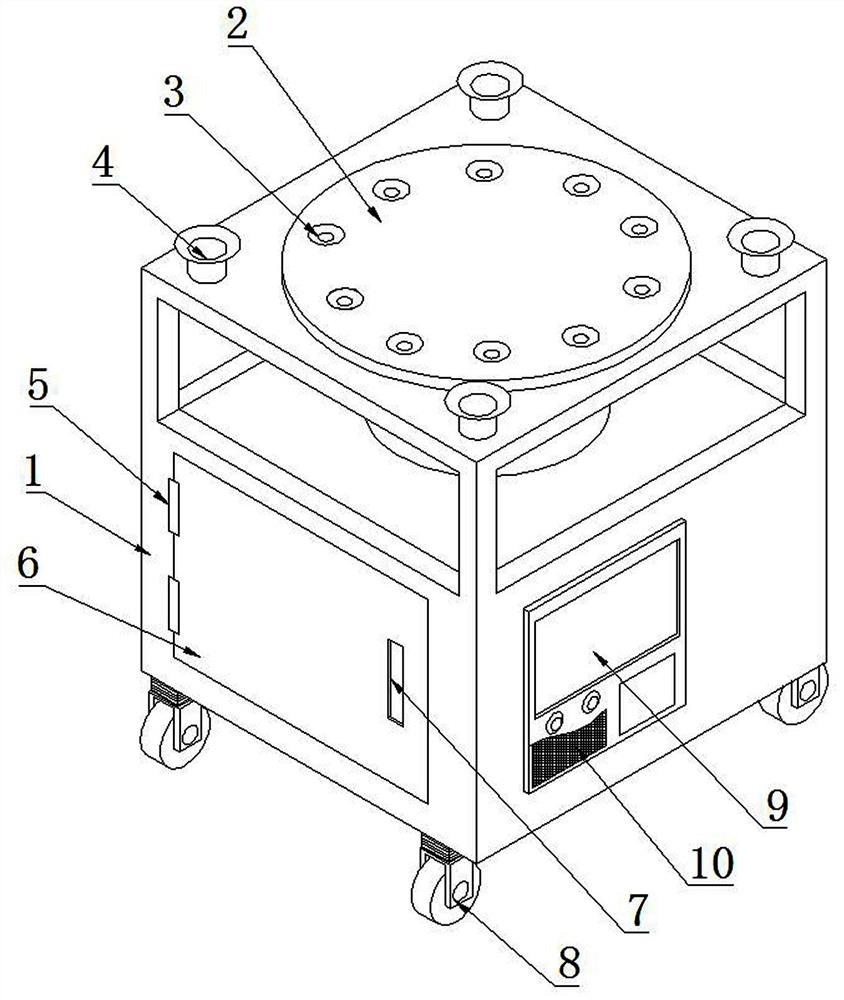

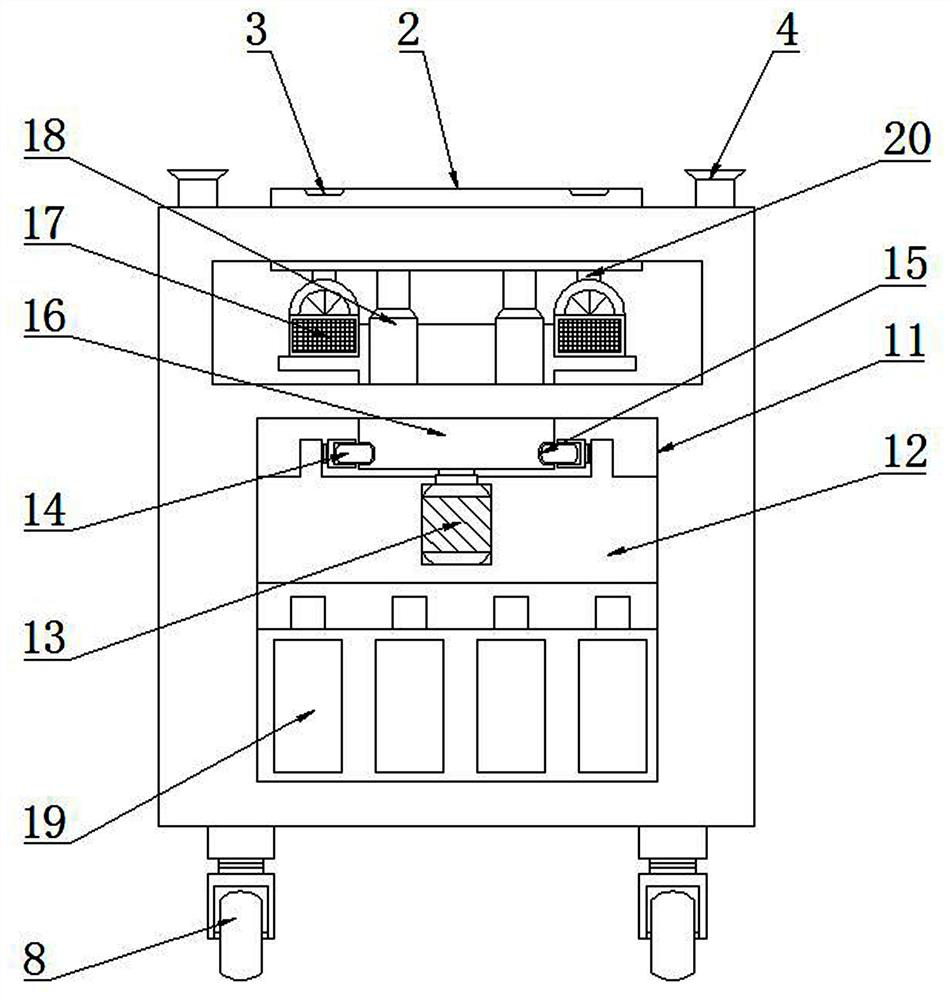

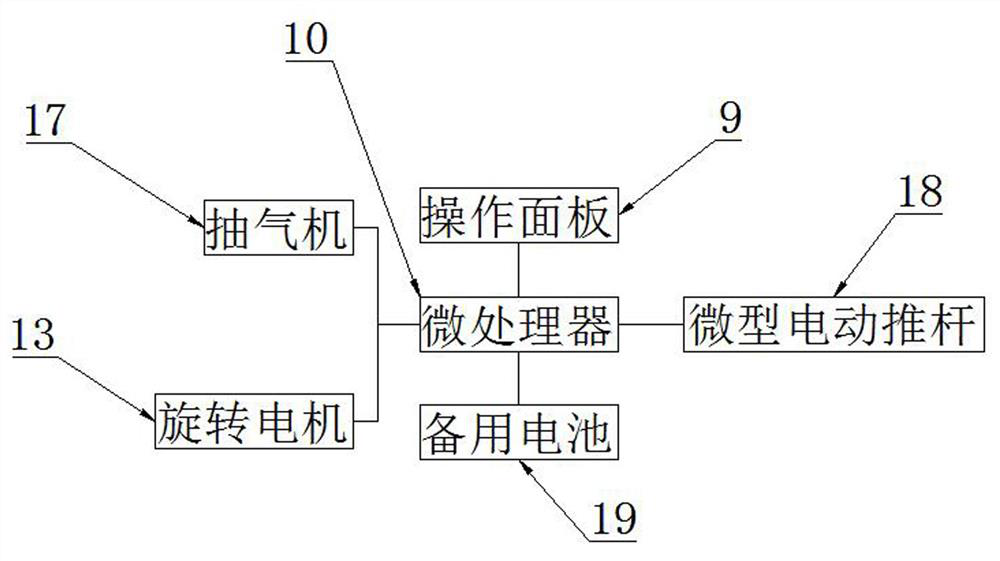

[0022] see Figure 1-3 , the present invention provides the following technical solutions: a pneumatic device for a glass cutting machine, including a workbench 1, a chamber 11 is provided inside the workbench 1, and the workbench 1 can support the glass cutting operation by setting the workbench 1. Under the action of the steering wheel 8, the overall device can be moved to the designated position, which is convenient for the user to cut the glass to be cut on the surface of the workbench 1. The inside of the chamber 11 is fixedly connected with a support plate 12, and the inside of the support plate 12 is fixedly connected with a rotating The motor 13 is provided with a rotating motor 13 that can drive the connecting plate 16 and the turntable 2 to rotate, which is convenient for the user to adjust the angle of the glass, and is also convenient for the user to perform cutting operations later. The output shaft of the rotating motor 13 is fixedly connected with the connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com