tofu cutting machine

A technology of tofu machine and cutter, applied in metal processing and other directions, can solve the problems of low per capita daily output, difficulty in industrial production, waste of raw materials, etc., to avoid tofu breakage or personnel injury, which is beneficial to industrial production and reduces workstations. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in combination with specific embodiments.

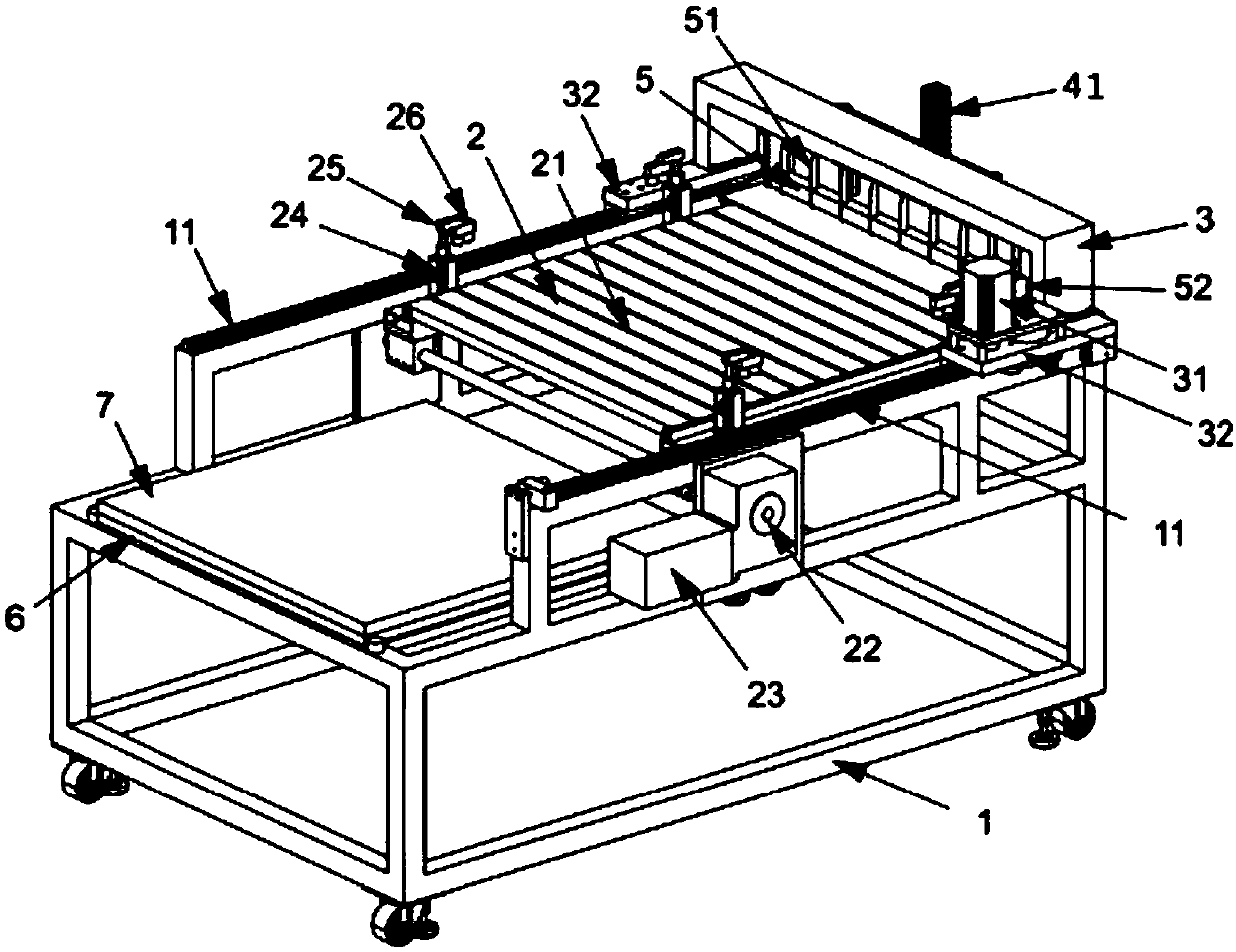

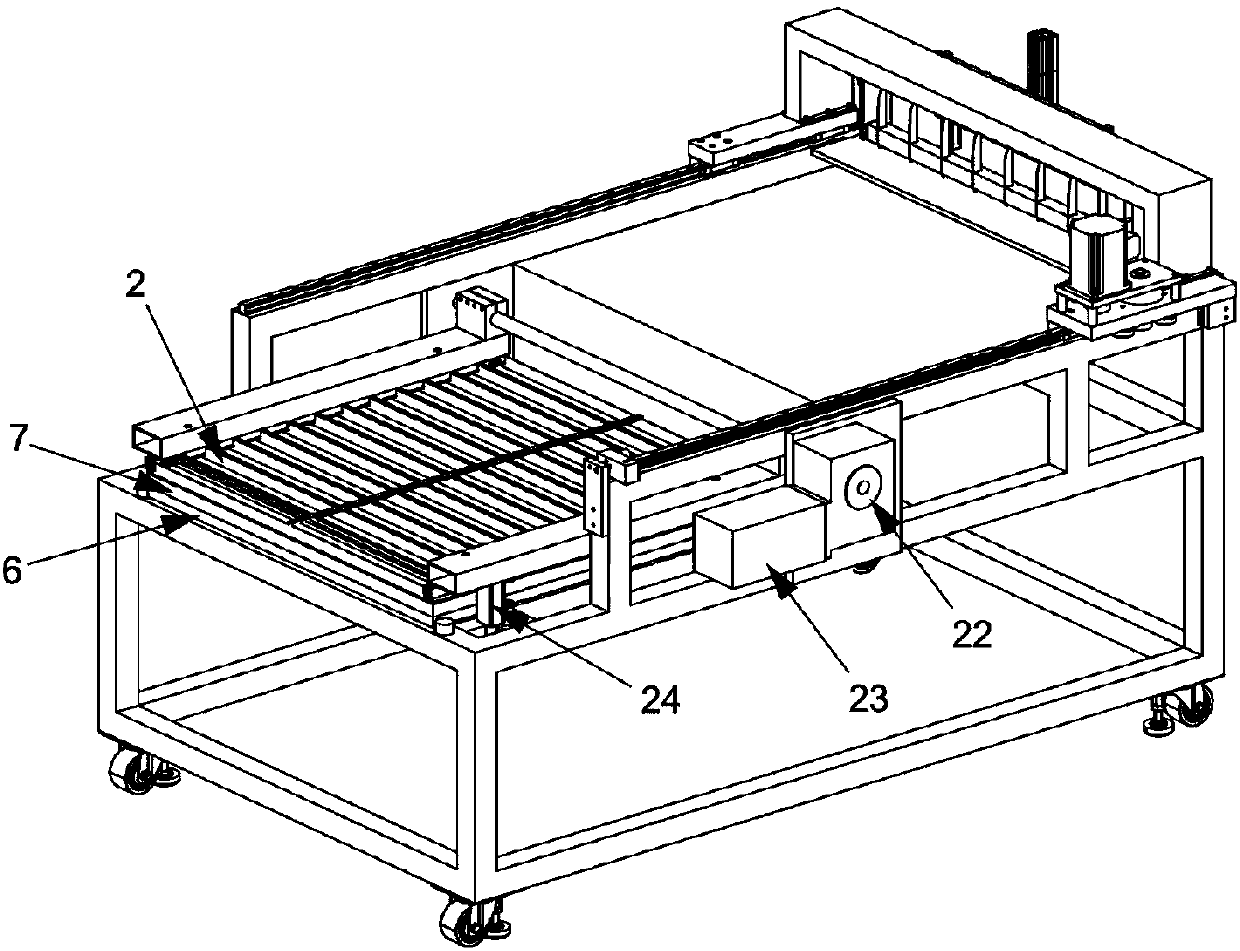

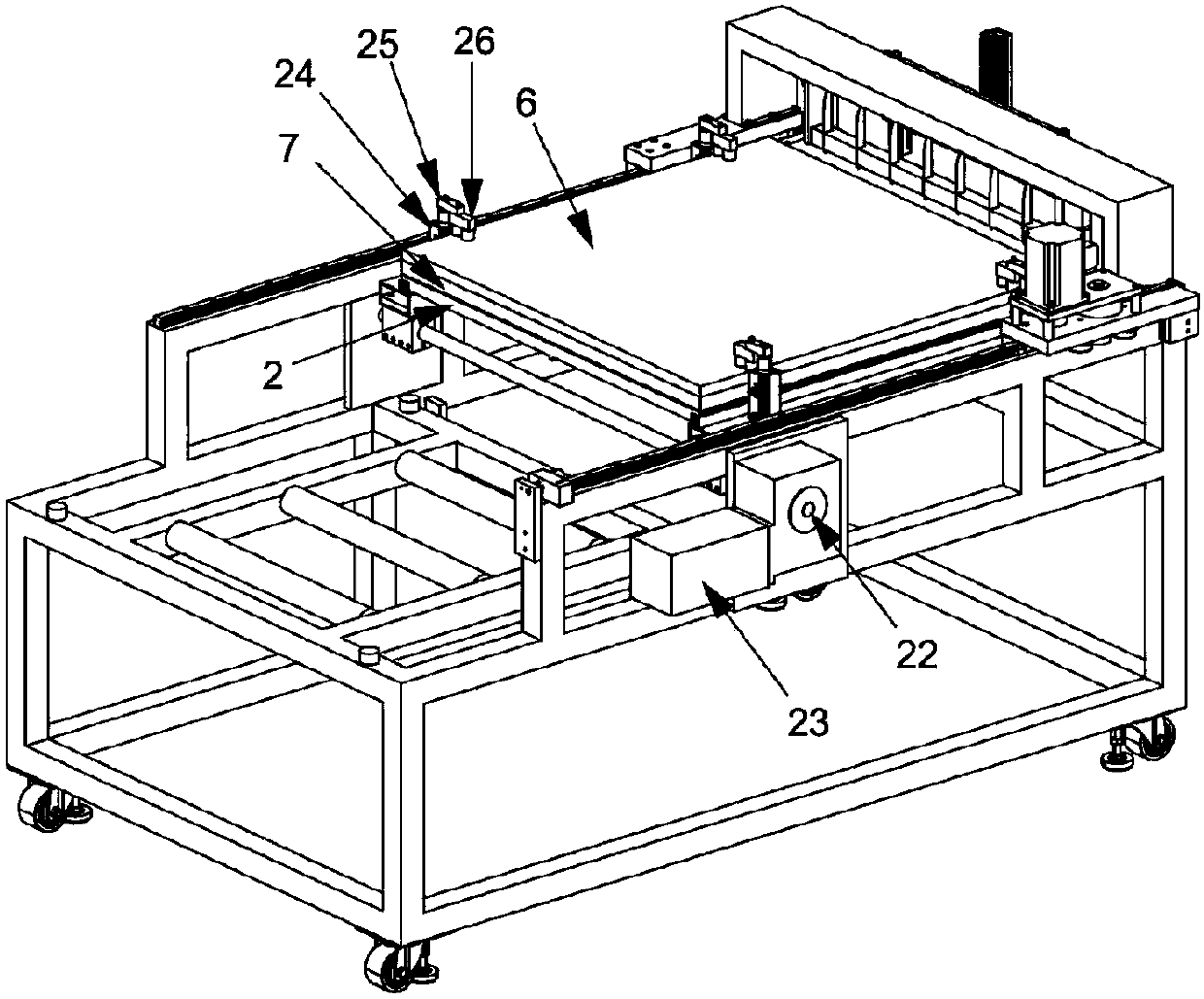

[0028] Such as Figure 1 to Figure 8 As shown, the bean curd cutting machine includes a frame 1, which is provided with a turnover plate 2 for loading tofu embryos 7, and a guide rail 11 is also provided on the front and rear sides of the frame 1, and the guide rail 11 is provided with a sliding fit The cutting knife support 3; Be provided with the horizontal cutting knife 4 that cooperates with cutting knife support 3, servomotor 31, horizontal cutting knife 4 is connected in the outer end of cutting knife support 3 by a horizontal cutting knife power unit 41, and horizontal cutting knife power The device 41 drives the horizontal cutter 4 to move up and down in the vertical direction, and the servo motor 31 drives the cutter support 3 to slide above the turnover plate 2 along the guide rail 11 .

[0029] As an improvement of the above-mentioned embodiment, both ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com