Grain drying tower of conveyor with bidirectional conveying belt

A technology for conveying belts and conveyors, which is applied in the direction of conveyors, conveyor objects, food processing, etc., can solve the problem of high grain fragmentation rate, achieve the effect of improving grain quality, reducing fragmentation rate, and increasing available space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

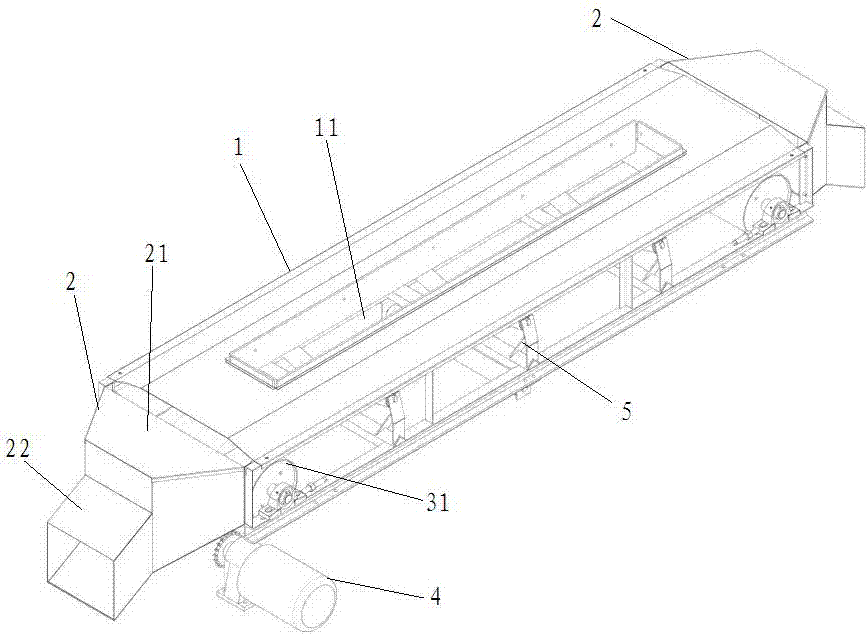

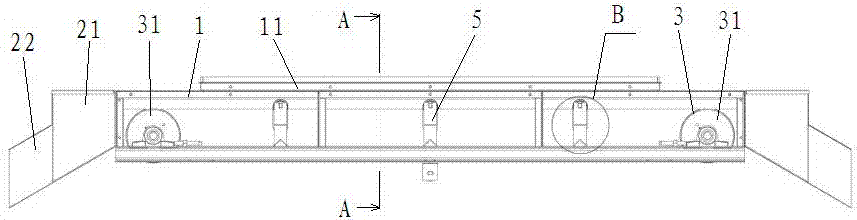

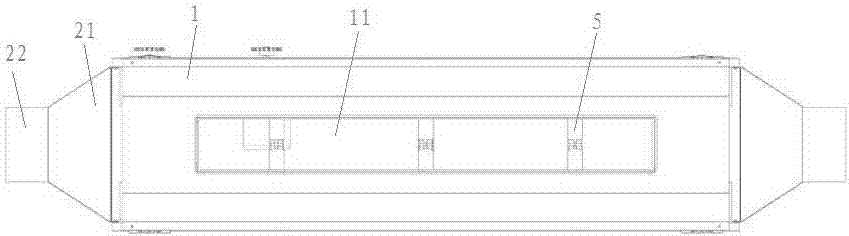

[0019] A kind of grain drying tower with two-way feeding belt conveyor of the present invention comprises tower body, is provided with hoisting device and two-way feeding belt conveyor in the tower body, the specific structure of two-way feeding belt conveyor is as follows Figure 1~Figure 5 As shown, the housing 1 is included, the two ends of the length direction of the housing 1 are provided with a hopper 2, the upper part of the housing 1 is provided with a feeding port 11, and the inside of the housing is provided with a conveyor belt 3 below the feeding port 11. The conveying belt 3 includes two rotating rollers 31 arranged in parallel and a belt wound around the periphery of the rotating rollers 31 . The two-way feeding belt conveyor also includes a driving machine 4 for driving the rotating roller 31 to move, and the driving machine 4 can rotate in both directions to control the conveying direction of the conveying belt 3 . The two rotating rollers 31 are respectively l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com