Wine liquid storage tank

A technology of piggy bank and wine liquid, which is applied in the field of liquor processing, can solve the problems of time-consuming, inability to separate the piggy bank, and rising costs, and achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

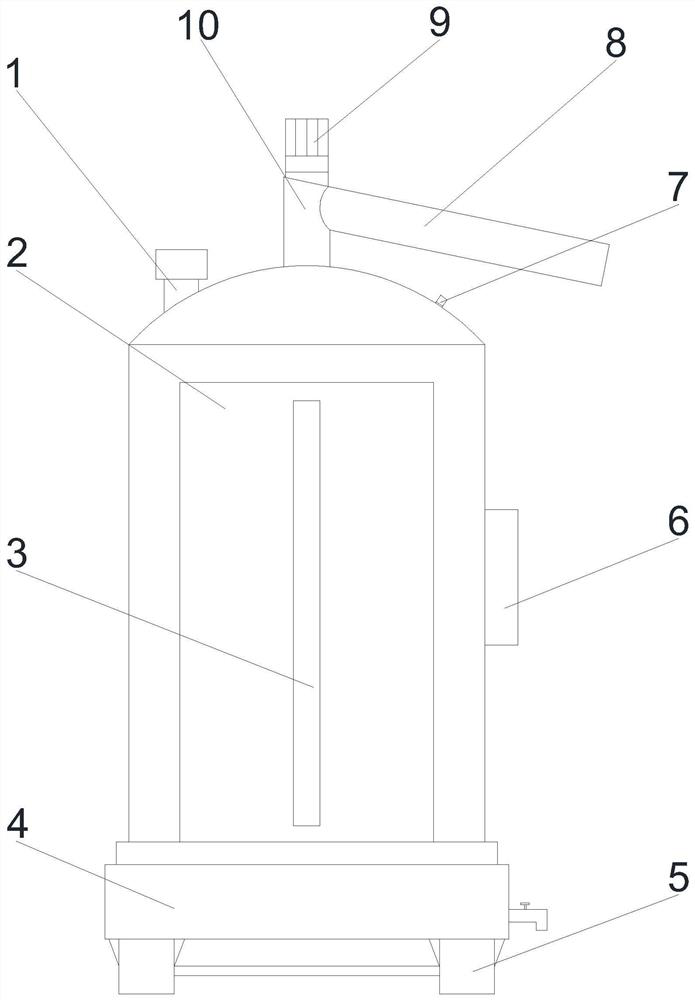

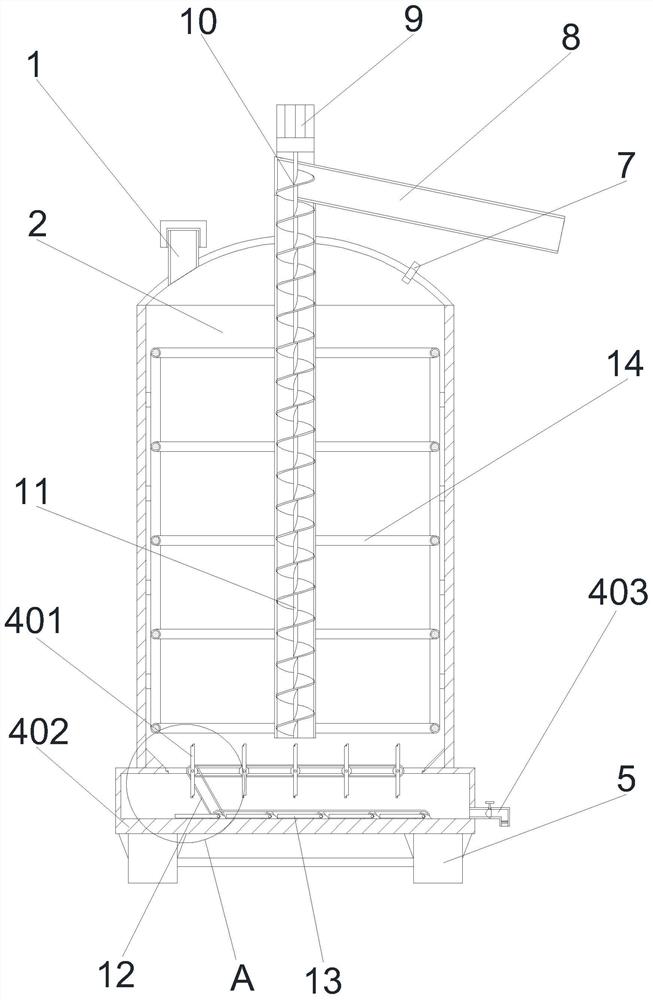

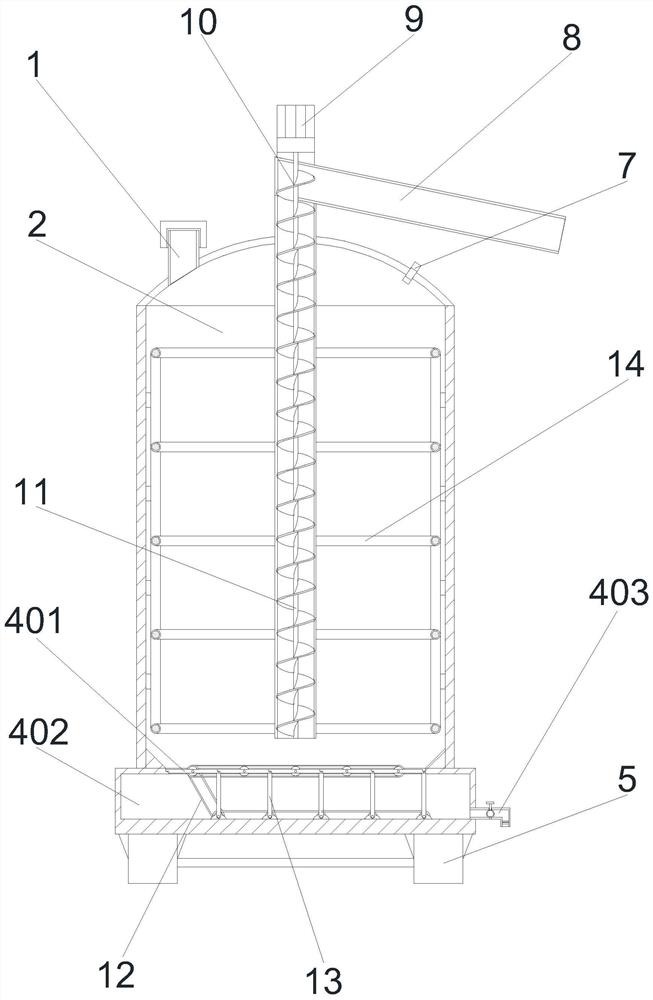

[0051] Please refer to Figure 1 to Figure 4 , a wine liquid storage tank, comprising a tank body 1, a separation mechanism 4 and a wine taking assembly, the top of the tank body 1 is provided with a feed port 1, and the bottom of the tank body 1 is provided with the separation mechanism 4, The wine taking assembly is arranged on the upper part of the tank body 1;

[0052] The separation mechanism 4 includes a separation chamber 402, a first driver and at least one separation partition 401, the upper part of the separation chamber 402 is provided with a first opening 16, and the bottom of the tank body 1 is provided with a 16, the first opening 16 is connected to the second opening, the separation partition 401 is rotatably connected to the first opening 16, the first driving member and the The separation partition 401 is driven and connected, and the bottom of the separation bin 402 is provided with a mixing outlet 403;

[0053] The upper surface of the separation chamber 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com