Profile steel, profile steel-UHPC composite plate, bridge deck slab and steel-UHPC composite beam bridge

A bridge deck and composite plate technology, applied in bridges, bridge parts, bridge materials, etc., can solve the problems of insufficient tensile capacity of the joint bottom surface, difficult to apply to large-span bridges, increased average plate thickness, etc., and achieves low construction difficulty. , The effect of high rigidity and small pouring amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

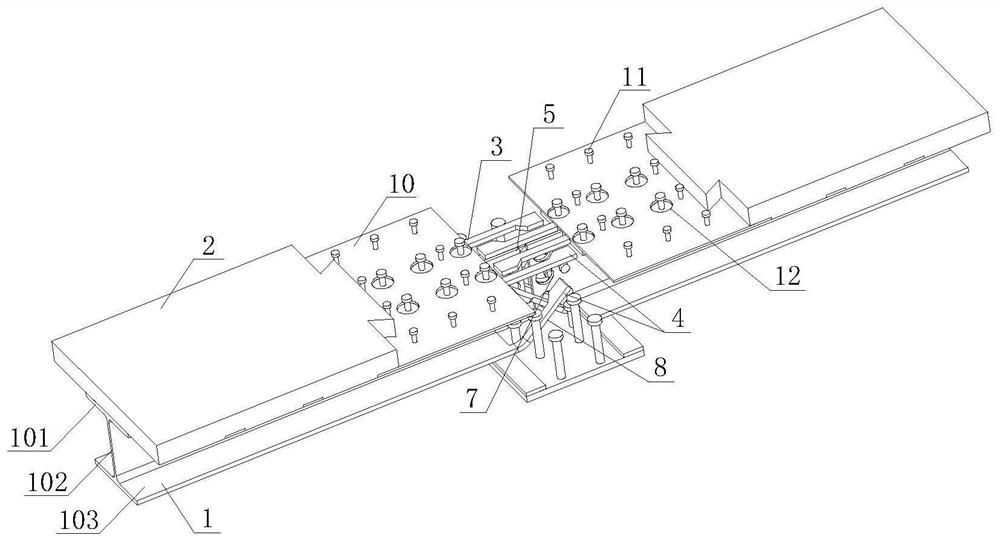

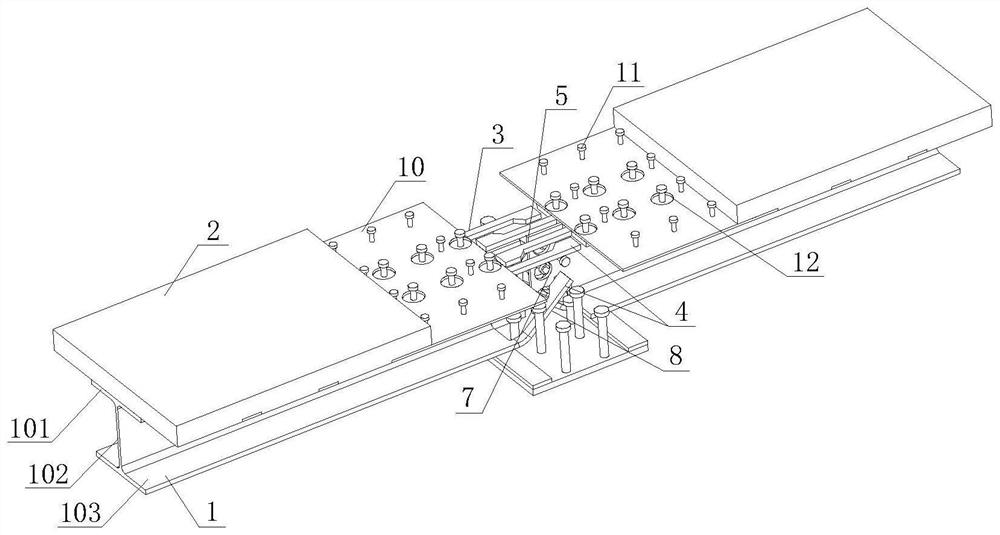

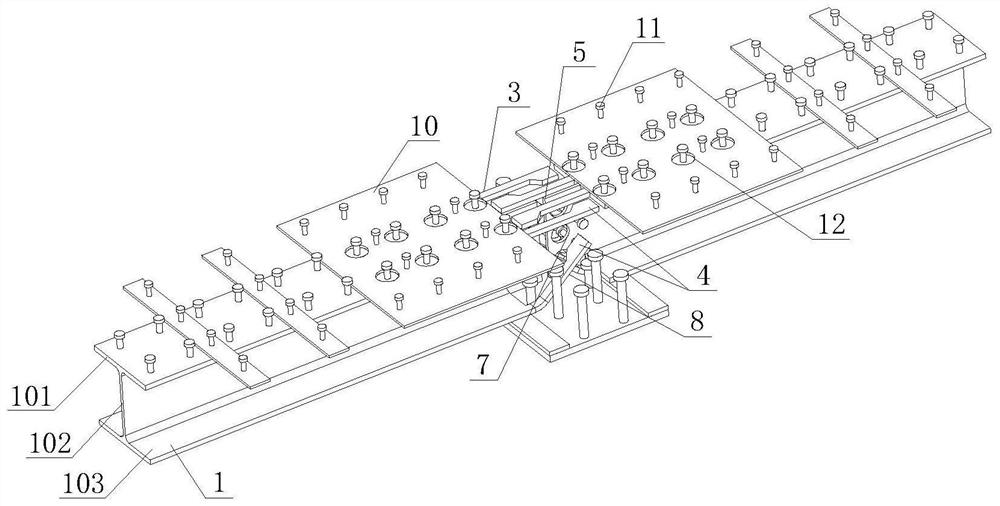

[0057] Such as Figure 1-Figure 8 As shown, the section steel of this embodiment includes an upper flange plate 101, a web 102 and a lower flange plate 103, the upper flange plate 101 is arranged on the top of the web 102, and the lower flange plate 103 is arranged on the bottom of the web 102, The end of at least one of the upper flange plate 101, the web 102 and the lower flange plate 103 extends outwards and is provided with an extension section (in this embodiment, the ends of the upper flange plate 101, the web 102 and the lower flange plate 103 The ends are all extended outwards and provided with extensions); the extensions at the end of the upper flange plate 101 are a plurality of first long straight bars 3 arranged at intervals, and the ends of the first long straight bars 3 are provided with enlarged parts 4 (Such as Figure 1-8 As shown, the shape of the enlarged part 4 is a rectangle with a transition edge); the extension section at the end of the web 102 is an ep...

Embodiment 2

[0069] Such as Figure 20-21 As shown, the section steel of this embodiment includes an upper flange plate 101 and a web 102, the upper flange plate 101 is arranged on the top of the web 102, and the ends of the upper flange plate 101 and the web 102 are all extended outward. Extension section; the extension section at the end of the upper flange plate 101 is a plurality of first long straight bars 3 arranged at intervals, and the end of the first long straight bar 3 is provided with an enlarged part 4; the extension section at the end of the web 102 For the epitaxial steel plate 5 (such as Figure 20 shown) or at least one second long straight strip 6 (such as Figure 21 As shown), the epitaxial steel plate 5 is provided with a plurality of first through holes 7 , and the end of the second long straight bar 6 is provided with an enlarged portion 4 .

[0070] The steel-UHPC composite panel of this embodiment includes a UHPC panel 2 and a plurality of the above-mentioned sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com