A kind of steelmaking auxiliary material drying device

A technology of drying device and auxiliary materials, applied in drying, drying machine, drying gas arrangement and other directions, can solve the problems of uneven drying, small heating area and low efficiency, and achieve high drying efficiency and large heating area. , The effect of uniform heating area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

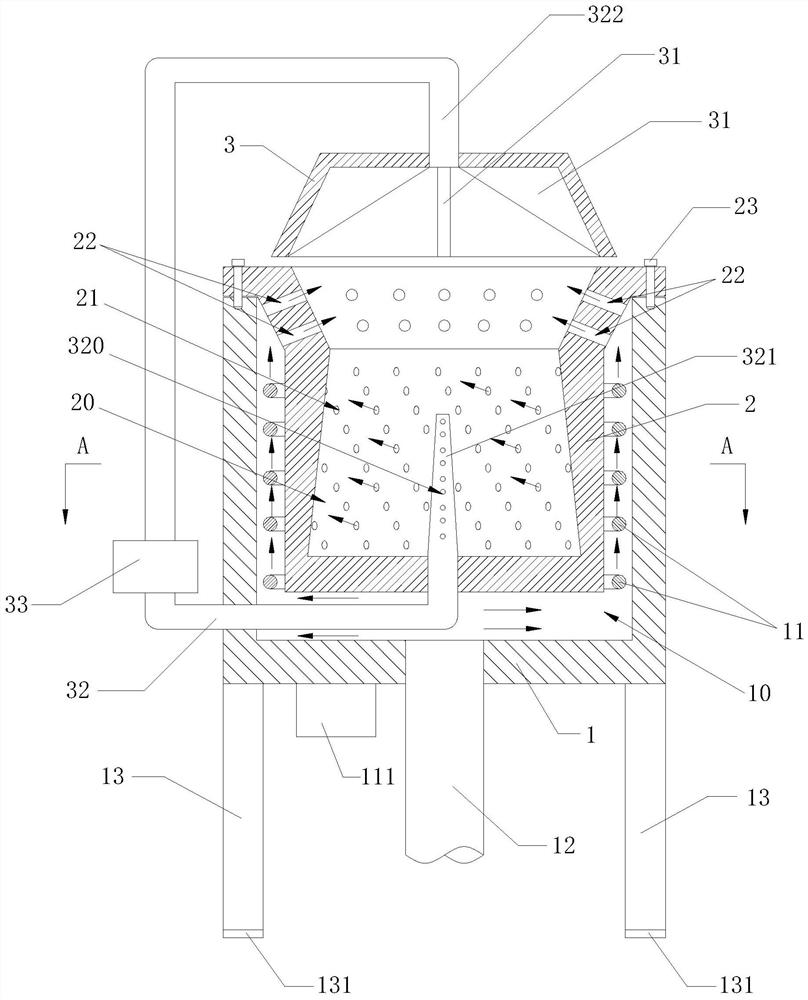

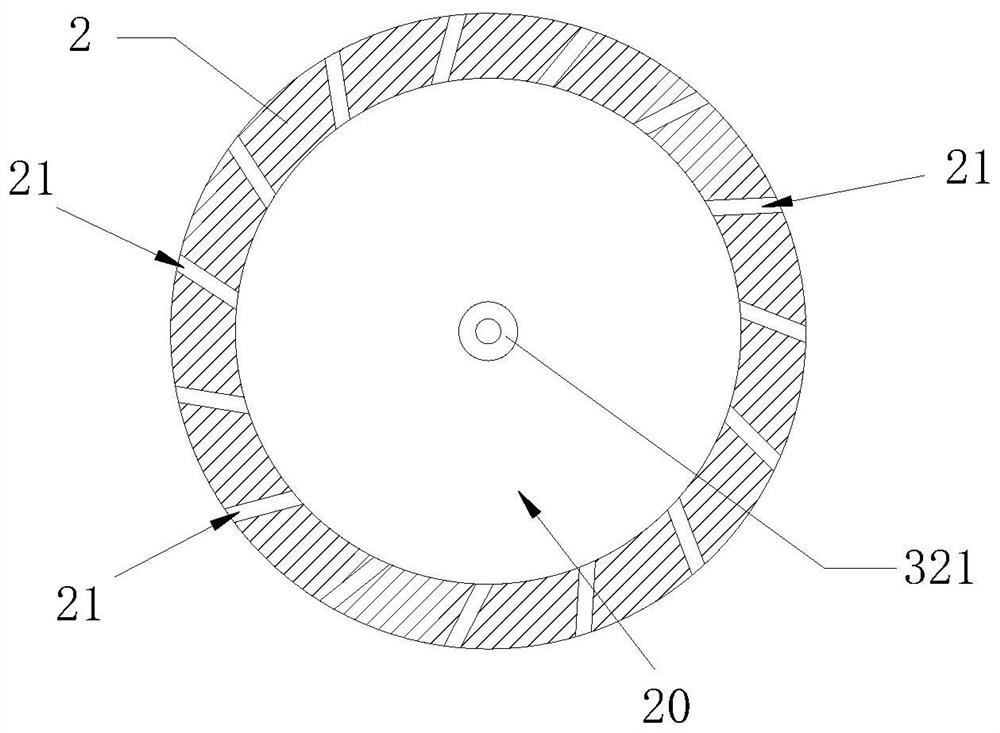

[0016] refer to figure 1 and figure 2 , a steel-making auxiliary material drying device, comprising an outer casing 1, a drying box 2, a main gas transmission pipe 12 and a secondary gas transmission pipe 32, the above-mentioned drying box 2 is provided with a drying chamber 20 with an open top, and the steel-making auxiliary materials are placed in the Drying in the drying chamber 20, the diameter of the drying chamber 20 gradually increases from the middle to the upper and lower ends, the upper and lower parts of the drying chamber 20 are in the shape of a truncated cone, the above-mentioned outer shell is sleeved on the outer side of the drying box 2, and the outer shell 1 is connected to the drying chamber. A shunt chamber 10 is formed between the chambers 20 , and a plurality of first air inlet holes 21 are evenly distributed on the lower side wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com