Wire and cable stripping equipment and stripping method thereof

A wire and cable and cable technology, applied in the field of wire and cable stripping equipment, can solve the problems of life danger, cable use danger, waste of time and energy, etc., and achieve the effect of strong adaptability and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

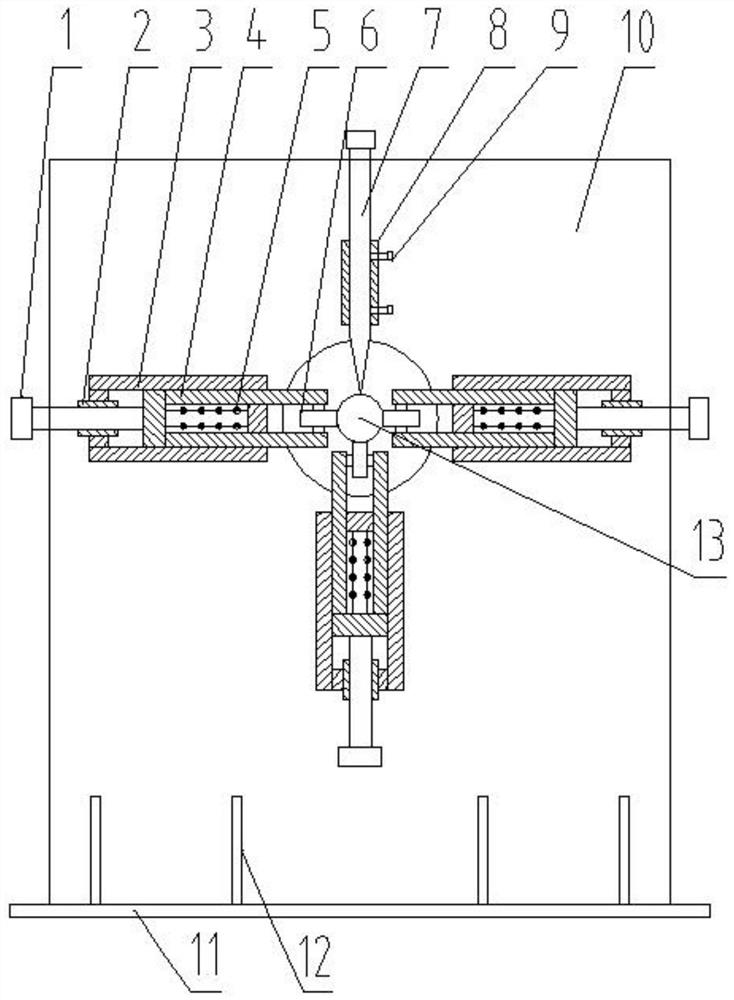

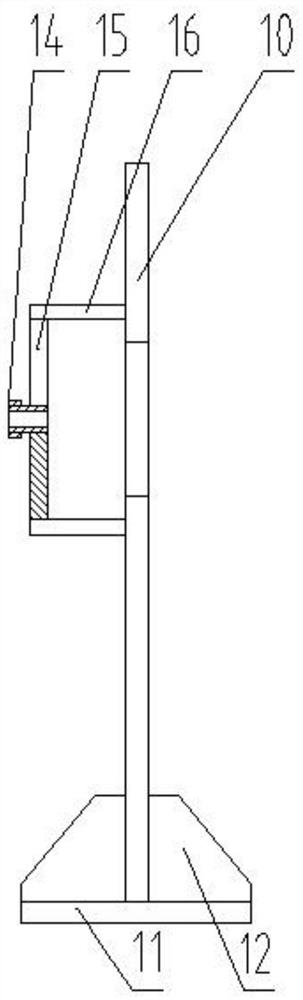

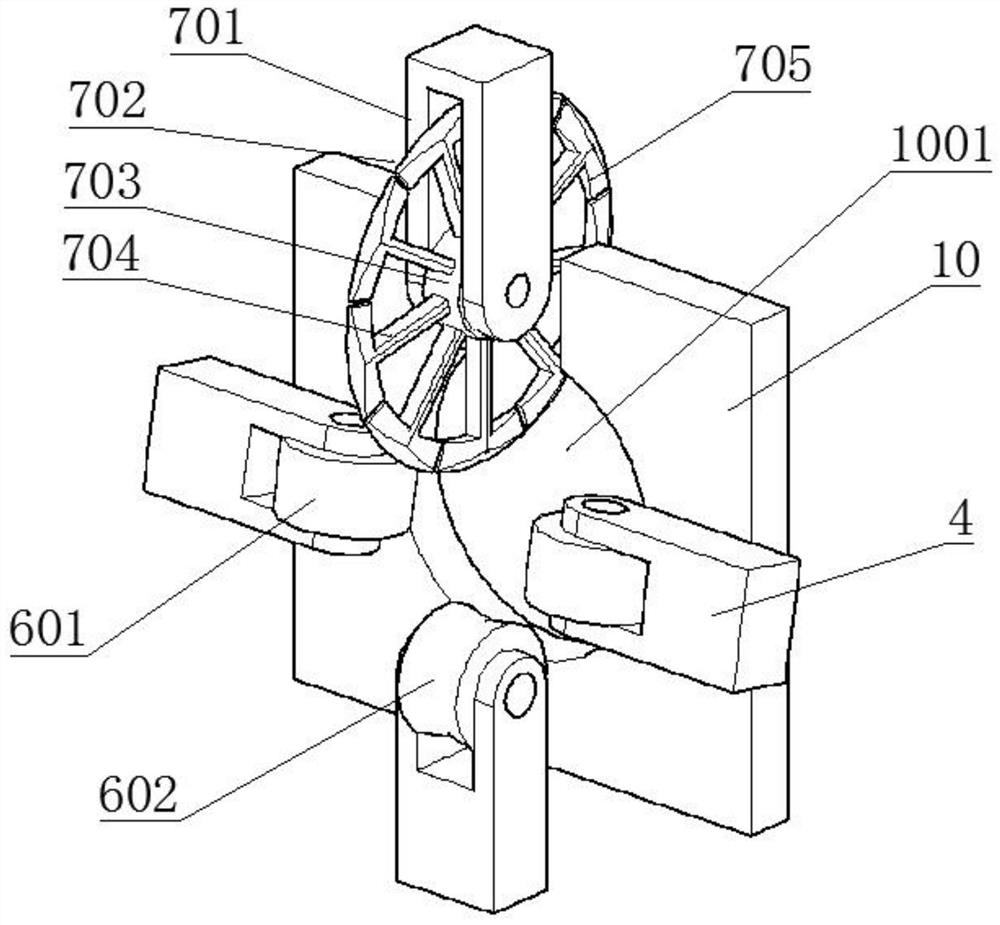

[0024] see Figure 1-2 , a kind of electric wire and cable stripping equipment, comprises roller 6, cutter 7, fixed plate 10, peeling sheath 14, is characterized in that: described fixed plate 10 is rectangular plate structure, and the middle part of described fixed plate 10 is provided with circular The through hole, the left, right and bottom of the circular through hole are provided with rollers 6, the rollers 6 are fixed on the front end of the slider 4, the slider 4 is a columnar structure as a whole, the front side of the slider 4 A bar-shaped groove is provided, the slider 4 is arranged in the cylindrical sliding sleeve 3, the sliding sleeve 3 is fixed on the front part of the fixed plate 10, and the front end of the sliding block 4 protrudes from the sliding sleeve 3 , the strip groove on the slider 4 is provided with a spring 5, one end of the spring 5 is connected with the slider 4, and the other end is connected with the end of the sliding sleeve 3, and the rear par...

Embodiment 2

[0027]A kind of wire and cable stripping equipment, including roller 6, cutter 7, fixed plate 10, peeling cover 14, it is characterized in that: described fixed plate 10 is rectangular plate-shaped structure, and the middle part of described fixed plate 10 is provided with circular through hole, the left, right and lower parts of the circular through hole are provided with rollers 6, and the rollers 6 are fixed on the front end of the slider 4, the slider 4 is in a columnar structure as a whole, and the front side of the slider 4 is provided with There is a strip-shaped groove, the slider 4 is arranged in the cylindrical sliding sleeve 3, the sliding sleeve 3 is fixed on the front part of the fixed plate 10, the front end of the sliding block 4 protrudes from the sliding sleeve 3, A spring 5 is arranged in the strip groove on the slider 4, one end of the spring 5 is connected with the slider 4, and the other end is connected with the end of the sliding sleeve 3, and the rear po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com