A kind of equipment for coconut cutting and shelling

An equipment and coconut technology, applied in metal processing and other directions, can solve the problems of time-consuming and manpower, waste of coconut juice, and high labor intensity, and achieve the effects of saving time, facilitating processing and increasing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

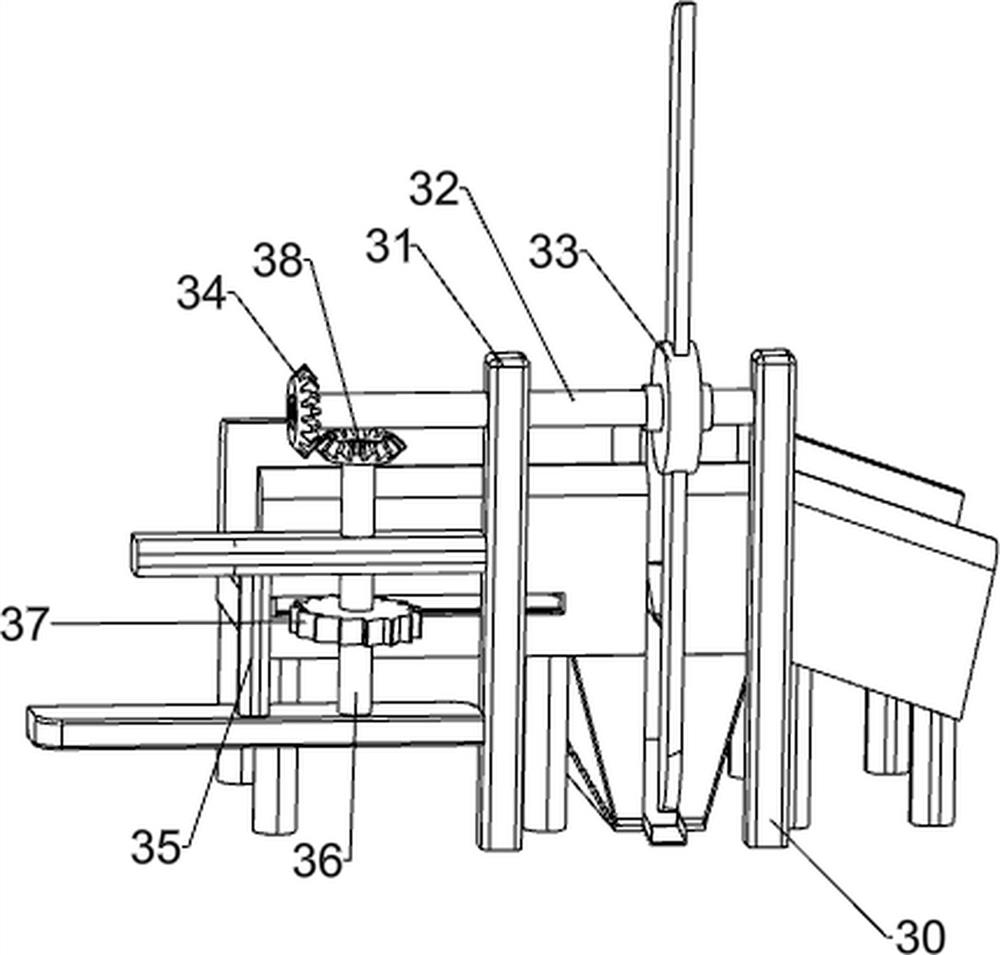

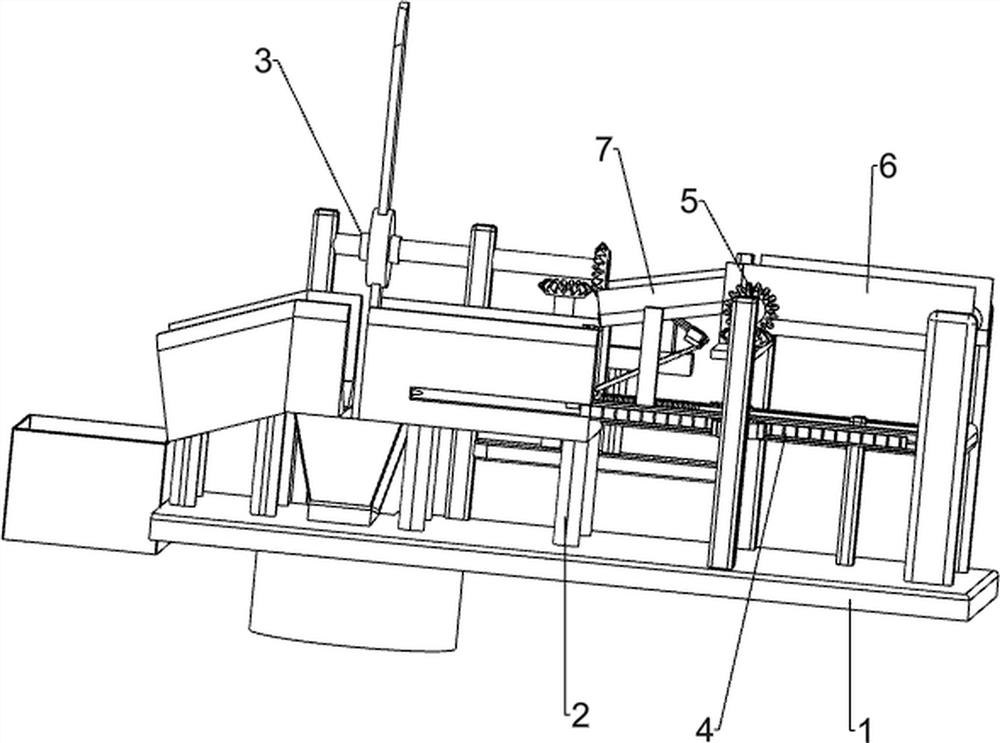

[0026] like figure 1 As shown, a coconut cutting and shelling equipment includes a base 1, a blanking mechanism 2, a cutting mechanism 3, a propulsion mechanism 4 and a feeding mechanism 5, and a blanking mechanism 2 is provided on the left side of the top of the base 1. After the top of the base 1 A cutting mechanism 3 is provided on the side near the feeding mechanism 2 , a pushing mechanism 4 is provided on the right side of the top of the base 1 , and a feeding mechanism 5 is provided on the top of the base 1 near the pushing mechanism 4 , and the pushing mechanism 4 is located below the feeding mechanism 5 .

[0027] When it is necessary to open the coconut shell, first, the staff first places the coconut on the feeding mechanism 5, and then controls the propulsion mechanism 4 to move to the left, so that the propulsion mechanism 4 drives the feeding mechanism 5 to move, and the feeding mechanism 5 transmits the coconut to the left. Then, control the propelling mechanism ...

Embodiment 2

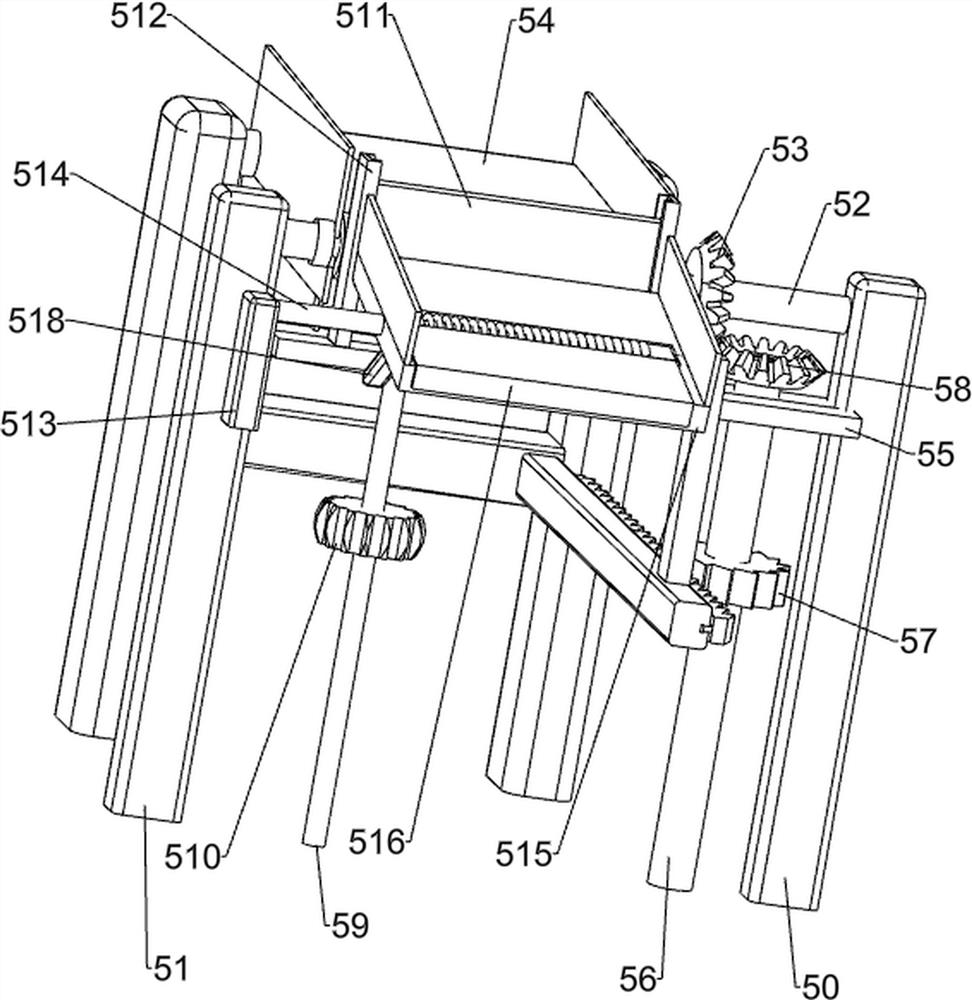

[0029] like figure 2 , image 3 , Figure 4 and Figure 5As shown, a coconut cutting and shelling equipment, on the basis of Embodiment 1, the unloading mechanism 2 includes a first support 20, a feeding chute 21, a second support 22, a discharging chute 23, a collection container 24 , a storage bucket 25 and a storage box 26, a first bracket 20 is evenly and symmetrically arranged in the middle of the top of the base 1, a feeding slot 21 is arranged between the tops of the four first brackets 20, and a second bracket is evenly and symmetrically arranged on the left side of the top of the base 1 22. A discharge chute 23 is provided between the top of the second bracket 22, a collection container 24 is provided between the feed chute 21 and the discharge chute 23, and a storage bucket 25 is placed under the discharge port of the collection container 24. A storage box 26 is provided on the side, and the storage box 26 is located below the discharge chute 23 .

[0030] When ...

Embodiment 3

[0038] like figure 1 As shown, an equipment for coconut cutting and shelling, on the basis of Embodiment 1 and Embodiment 2, also includes a first protective plate 6, and the first protective plate 6 is symmetrically arranged on both sides of the pulley assembly 54.

[0039] When the propulsion mechanism 4 controls the pulley assembly 54 to convey the coconut to the left, the coconut can be prevented from rolling off from the pulley assembly 54 by the first protective plate 6 .

[0040] A second protective plate 7 is also included, and the second protective plate 7 is symmetrically arranged on both sides of the blanking plate 515 .

[0041] When the coconut rolls along the inclined surface of the blanking plate 515 , the coconut can be prevented from rolling off from the blanking plate 515 by the second protective plate 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com