a flame stabilizer

A flame stabilizer and wall surface technology, which is applied in combustion methods, combustion chambers, combustion equipment, etc., can solve the problems of large temperature difference on the wall surface and affect the wall surface temperature of the flame stabilizer, so as to reduce wall temperature, reduce thermal stress, and facilitate combustion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

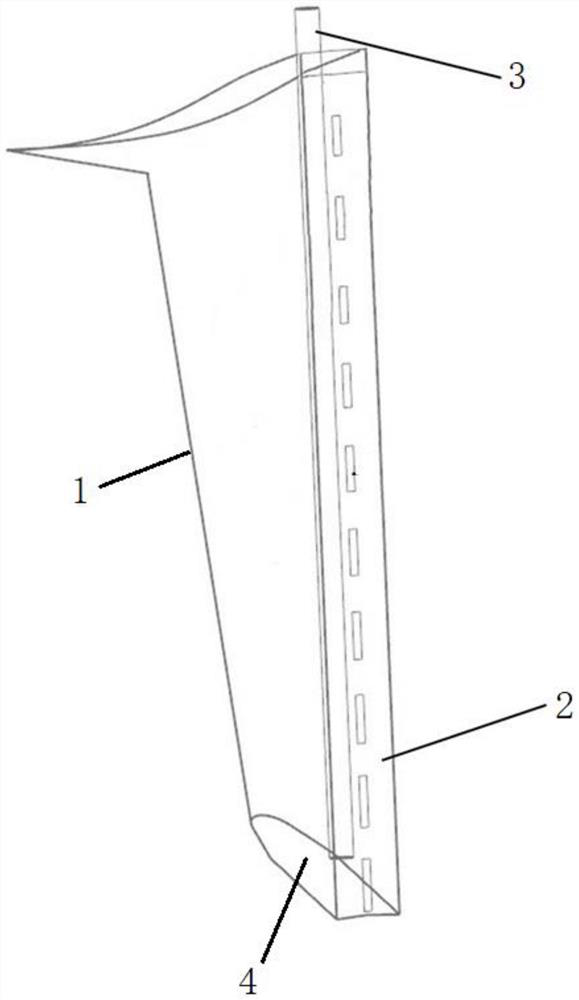

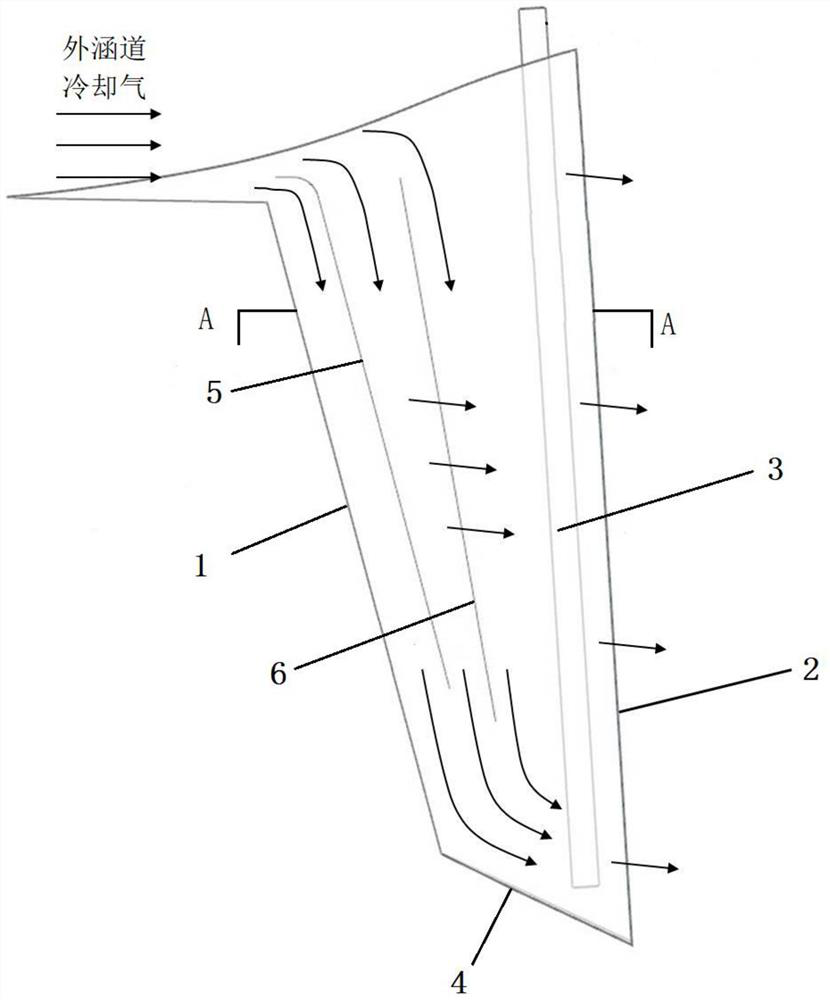

[0028] The flame stabilizer described in the prior art is as figure 1 As shown, it is a hollow cylinder with an open top and a closed bottom end, including a windward wall 1, a rear end wall 2 and a bottom end 4, the windward wall 1 and the rear end wall 2 are connected by a side wall, and the flame is stable An oil injection rod 3 with the same extension direction is also arranged in the device, an outlet 21 is arranged on the rear end wall 2, and the open end of the flame stabilizer communicates with the outer duct.

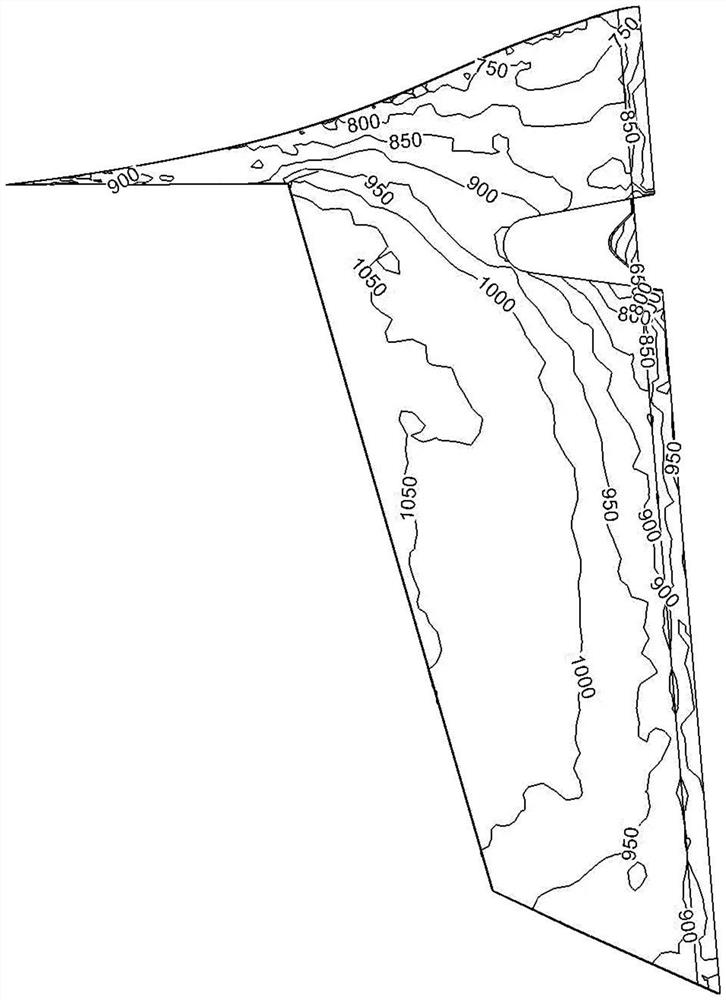

[0029] At this time, the wall temperature contour of the flame holder is as follows: figure 2 As shown in Fig. 1, due to the sudden expansion of the flow channel of the cooling air in the outer channel when it enters the flame holder, a wall-attached separation zone is formed inside the leading edge, and the outer channel cold flow cannot effectively cool the windward side of the flame holder, and the flame is stable. The temperature on the windward side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com