S-shaped rotor structure for stainless steel roots flowmeter

A technology of waist wheel flowmeter and rotor structure, applied in the direction of volume measurement, liquid/fluid solid measurement, measurement device, etc., can solve the problems of reduced service life and increased use cost, and achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below, in conjunction with accompanying drawing and specific embodiment, make preferred description to the invention:

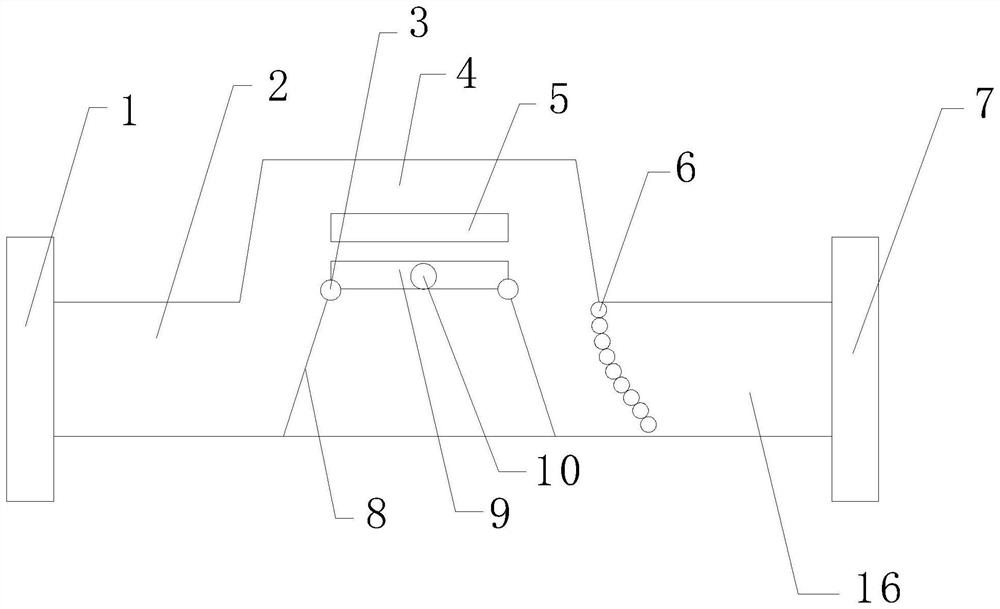

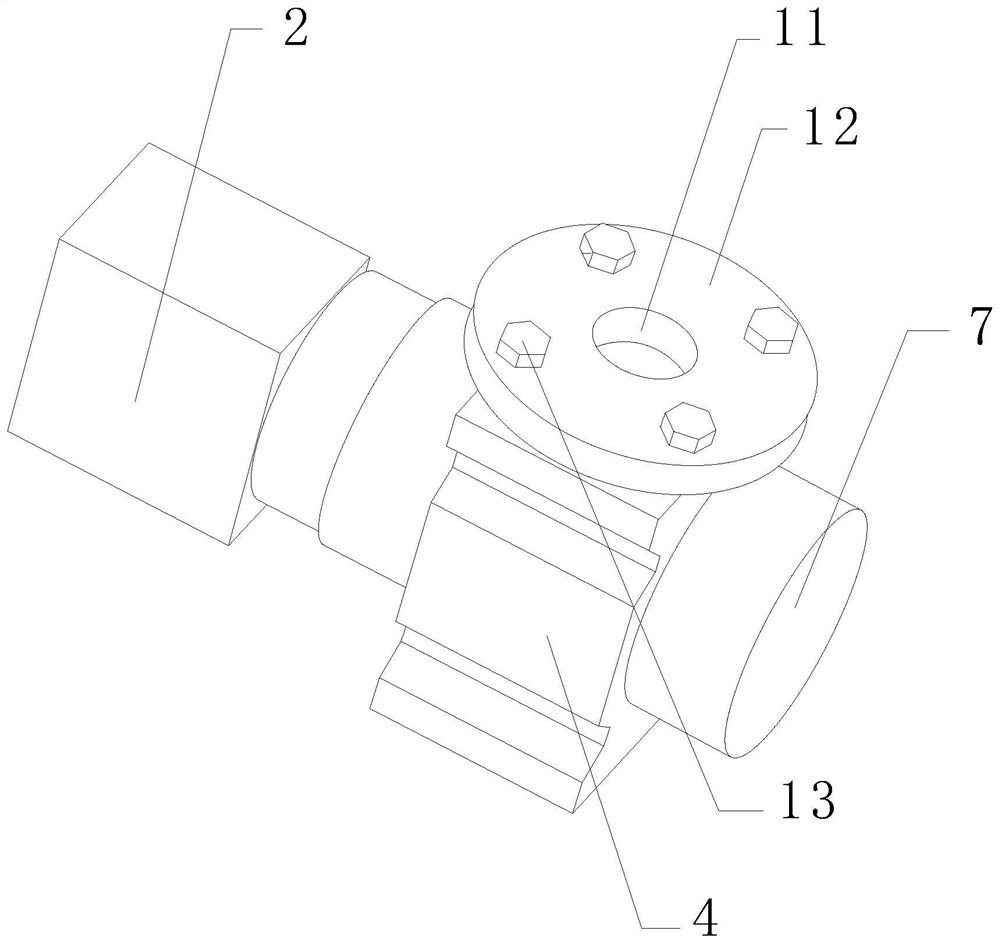

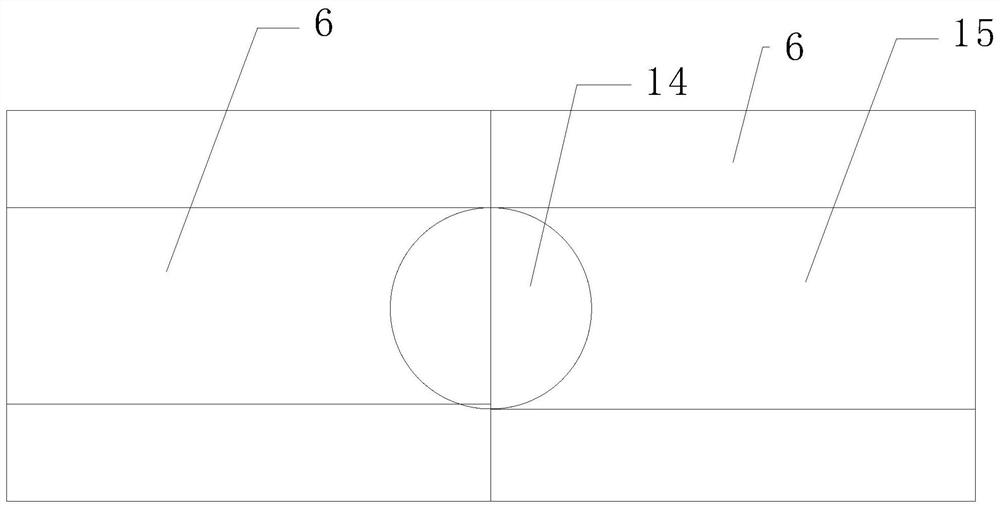

[0023] see Figure 1-4 According to an embodiment of the present invention, an S-shaped rotor structure for a stainless steel waist wheel flowmeter includes an air inlet 1, a waist wheel flowmeter 5, a structural body 2, a hexagonal screw 13, a fixing hole 11, and a flange 12 , the swing plate 9 and the metering chamber 4, the swing plate 9 is fixedly connected to the inside of the metering chamber 4 through the action of the roller 10, the lower surface of both ends of the swing plate 9 is fixedly connected with a rotating shaft 3, and the rotating shaft 3 One end is fixedly connected with a deflector 8, the number of the rotating shaft 3 and the deflector 8 is two, and the two rotating shafts 3 and the deflector 8 are arranged symmetrically through the central axis of the swing plate 9 One side of the rotating shaft 3 is provided with a plurality of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com