Intelligent construction waste sorting device

A sorting device and construction waste technology, which is applied in construction waste recycling, magnetic separation, solid separation, etc., can solve the problems of manual operation, low sorting efficiency, and easy blockage of the filter, so as to avoid manual operation and save resource effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

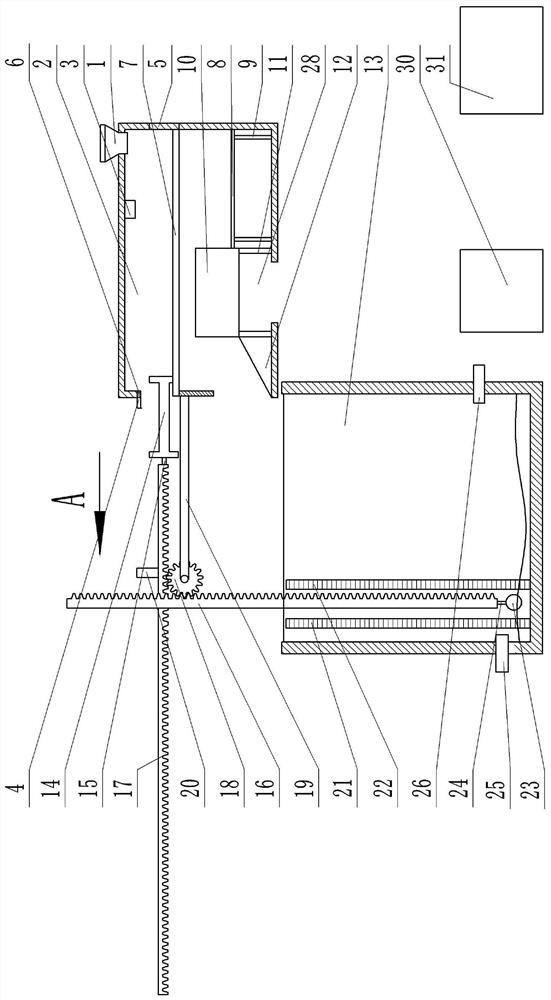

[0025] as attached figure 1 Shown:

[0026] The box body 2 is a construction waste sorting device for separating metal and fine materials in the construction waste. The box body 2 is provided with a funnel 1, and the funnel 1 is used for throwing construction waste, and the funnel 1 is arranged on the uppermost end of the box body 2.

[0027] The inside of the box body 2 is provided with a conveyor belt 8, and one end of the conveyor belt 8 is correspondingly arranged below the funnel 1. The conveyor belt 8 is connected to the inside of the box body 2 through a bracket 9. The uppermost end of the box body 2 is provided with an electromagnet 3, and the electromagnet 3 and Conveyor belt 8 is arranged correspondingly, and electromagnet 3 has magnetic force after being energized, can absorb the metal in the construction waste. The electromagnet 3 is energized, and the construction waste is put into the funnel 1, and the waste falls on the conveyor belt 8, and the electromagnet 3...

Embodiment 2

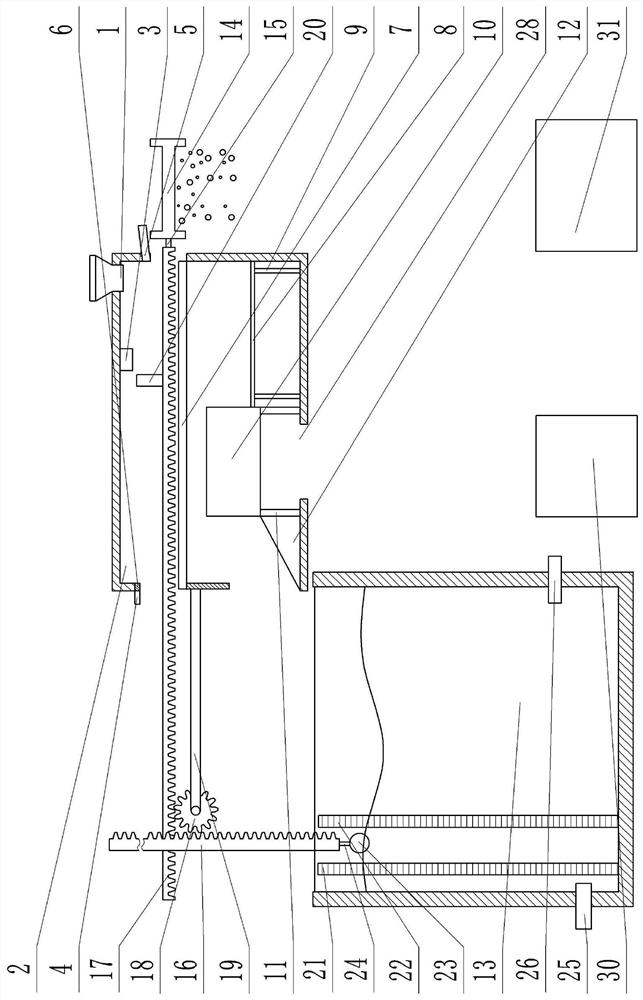

[0045] as attached Figure 5 Shown:

[0046] In the settling tank 13, a side near the first reversing door 5 is provided with a second floating ball 34, the second floating ball 34 can float on the water surface of the settling tank 13, and the second floating ball 34 both sides are provided with the second floating ball for limiting the second floating ball. The third filter screen 32 and the fourth filter screen 33 that the ball 34 moves laterally, the second floating ball 34 is provided with a connecting rod 36 fixedly connected, and the uppermost part of the connecting rod 36 is fixedly connected with a magnet 35 .

[0047] During the specific operation, when the garbage in the settling tank 13 increases, the water level rises, so that the first floating ball 23 floats upwards, so that the push rod 24 also moves upwards, the vertical rack 16 moves upwards, and the gear 18 moves clockwise. Rotate, so that the transverse rack 17 moves towards the direction close to the box ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com