Drilling tool capable of realizing low-roundness error drilling

A roundness error and drilling tool technology, which is applied in the field of drilling tools, can solve the problems of short service life of the tool, and achieve the effects of improving processing efficiency, enhancing rigidity, and reducing roundness error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

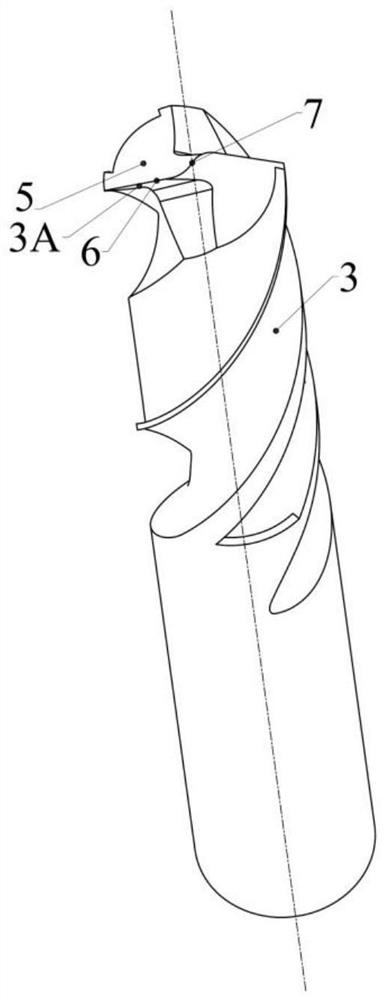

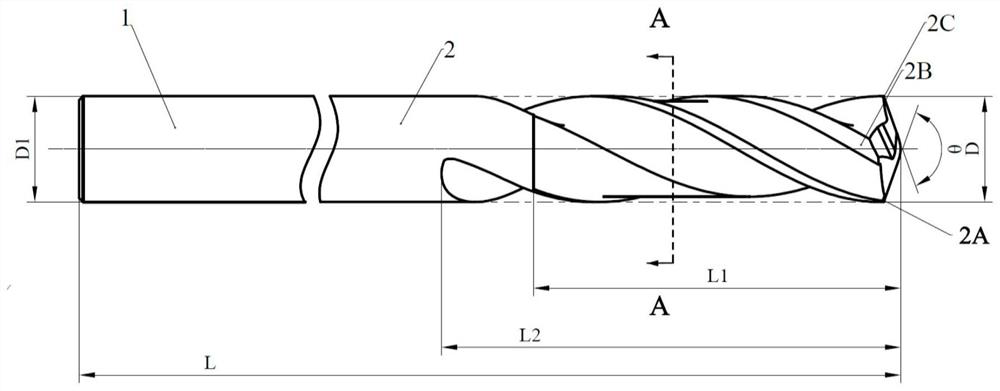

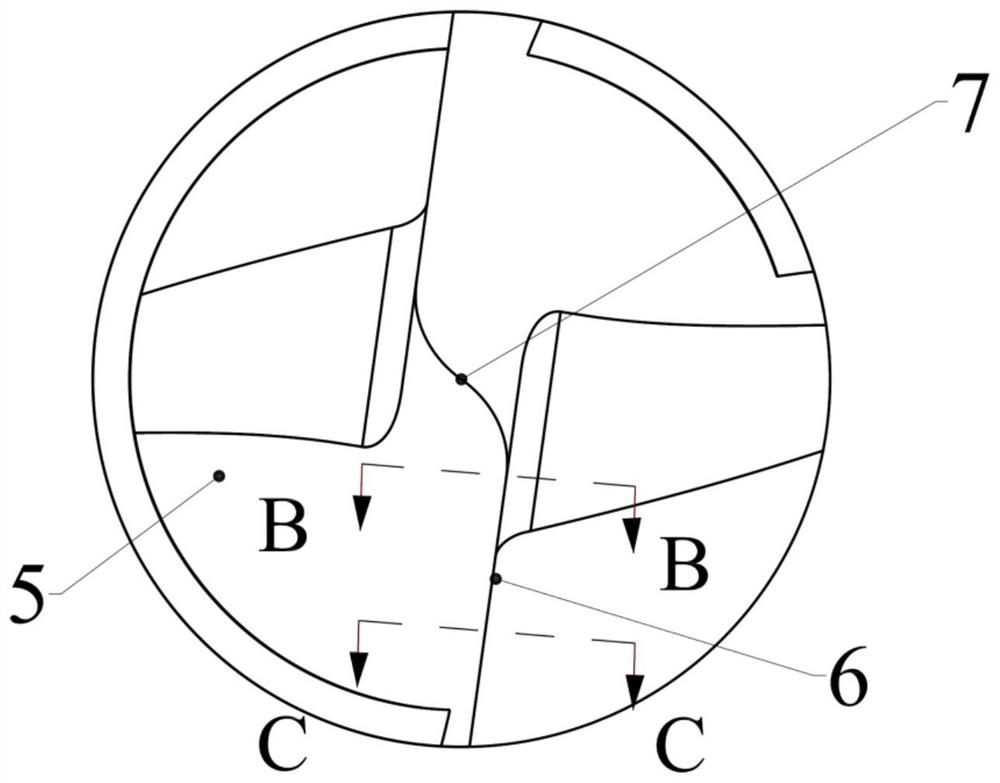

[0016] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that the drawings are in simplified form and are not made in exact proportions, and are only used for intuitive and visual explanation of the embodiments of the present invention.

[0017] Referring to the accompanying drawings, the present invention is a drilling tool capable of making holes with low roundness errors. It includes a shank 1 and a blade 2 connected to the shank 1. Chip flute3. The two blades and the two main flutes 3 are helically symmetrically distributed along the central axis of the drill bit. In order to solve the problem of drill centering, the force of the tool is balanced during the drilling process, and the roundness error is reduced. The two blades A parabolic chisel edge 7 is designed at the center of the front end face of the blade portion 2 . The two blade lobes form a parabolic chisel edge 7 at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com